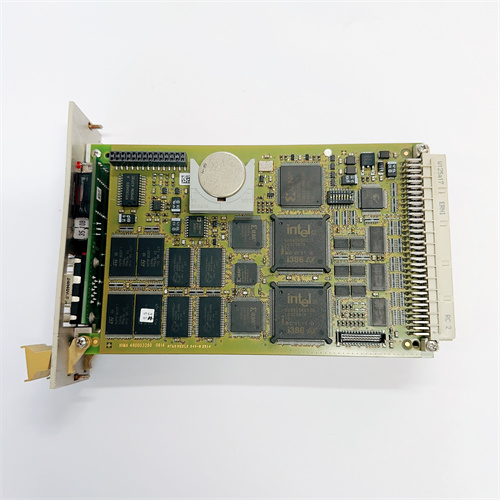

Description

The HIMA H51Q-H B5233-2 997235233 is a high-availability quad redundant controller module designed for HIMA’s H51q safety system platform. This advanced safety logic solver provides SIL 3 certified processing capability for critical emergency shutdown, fire & gas, and burner management applications in the most demanding industrial environments. The HIMA H51Q-H B5233-2 997235233 represents the pinnacle of fault-tolerant safety controller technology, delivering 1oo4D (one-out-of-four with diagnostics) architecture for applications requiring maximum availability without compromising safety integrity.

Product Overview and Description

The HIMA H51Q-H B5233-2 997235233 functions as the main processing unit within HIMA’s H51q high-availability safety system, executing safety function logic and diagnostic self-tests with quad redundant computation and quadruple voting logic. This module incorporates four independent microprocessor channels operating in parallel, each executing identical safety application programs and continuously cross-checking results through hardware comparators and software voting algorithms. The HIMA H51Q-H B5233-2 997235233 maintains safe operation with up to three simultaneous processor failures, providing unprecedented fault tolerance for safety-critical applications. Designed for continuous operation in extreme environments, the module features rugged industrial construction, extended temperature component selection (-40°C to +70°C), conformal-coated circuit boards, and comprehensive electromagnetic compatibility for high-interference industrial environments. Front-panel LED indicators provide immediate visibility of processor health, synchronization status, and channel voting results.

Key Parameters and Specifications

- Safety Integrity: SIL 3 per IEC 61508, SIL 4 per EN 50129, AK 7 per DIN V 19250, PL e per ISO 13849.

- Architecture: 1oo4D (one-out-of-four with diagnostics), quad redundant processing.

- Processors: 4x 32-bit RISC CPUs, lockstep operation with hardware comparison.

- Program Memory: 32 MB application memory, 16 MB data memory with ECC protection.

- Cycle Time: <25 ms typical for 1000 safety functions, deterministic execution.

- Fault Tolerance: Safe operation with up to 3 simultaneous processor channel failures.

- Diagnostic Coverage: >99.9% DCavg, continuous self-test of all critical components.

- Communication: Safeethernet, PROFIsafe, SafetyNET, redundant communication paths.

- I/O Capacity: 1024 safety I/O points distributed, 256 local I/O modules.

- Voting Logic: 2oo4D, 2oo3, 1oo2D, 1oo3 configurable per application requirements.

- Power Consumption: 15 W typical, 25 W maximum from 24 VDC redundant power supply.

- Certifications: TÜV Rheinland functional safety certified, CE, UL, CSA, ATEX, IECEx, DNV-GL, SIL 4 certified for rail applications.

- MTBF: >100 years demonstrated, >500 years calculated per SN 29500.

- Proof Test Interval: 20 years minimum without dangerous failure accumulation.

Advantages and Functional Benefits

The HIMA H51Q-H B5233-2 997235233 delivers unparalleled safety and availability advantages:

- Quadruple Redundancy: Four independent processing channels with hardware comparison and software voting maintain safe operation with up to three simultaneous processor failures, enabling continued production during fault conditions and extended maintenance windows.

- Hot-Repair Capability: Faulted processor channels can be replaced online without process interruption or safety function degradation; the HIMA H51Q-H B5233-2 997235233 automatically reintegrates replacement channels with full synchronization.

- Extended Proof Test Interval: >99.9% diagnostic coverage enables 20-year proof test intervals, eliminating routine functional testing costs and reducing operational expenditures by approximately 70% over system lifecycle.

- Mixed Criticality Support: Simultaneous execution of SIL 1 through SIL 3 functions on single platform with complete separation and no adverse interaction, reducing hardware requirements by up to 75%.

- Cyber-Secure Architecture: Built-in cybersecurity features including secure boot, encrypted communication, and role-based access control per IEC 62443-3-3.

Application Fields and Use Cases

The HIMA H51Q-H B5233-2 997235233 is exclusively deployed in applications demanding maximum safety integrity and operational availability:

- Offshore Production Platforms: Complete platform emergency shutdown, fire & gas detection, and process shutdown in single system; continued operation through single/multiple channel faults eliminates production deferment.

- FPSO Vessels: Integrated marine and process safety systems with SIL 3 certification and classification society approval; dynamic positioning interface and cargo handling safety.

- Refineries: Critical process unit safety systems requiring maximum availability; alkylation unit, hydrocracker, and catalytic cracker protection with zero unplanned trips.

- Nuclear Facilities: Safety-related control and monitoring functions requiring highest reliability and fault tolerance.

- Chemical Processing: High-hazard batch reactor protection, toxic material storage safety systems, and interlocking.

- Railway Signaling: SIL 4 certified interlocking and train control systems requiring 1oo4D architecture.

Competitor Comparison

The HIMA H51Q-H B5233-2 997235233 occupies the highest tier of safety controller technology. Honeywell Safety Manager FSC provides SIL 3 capability with 1oo2D architecture but maximum fault tolerance of single channel failure, versus HIMA H51Q-H B5233-2 997235233‘s three-channel fault tolerance. Siemens S7-400F/FH offers SIL 3 with 1oo2D fail-safe and 1oo2D high-availability configurations but requires 4 modules to achieve quad redundancy at significantly higher cost and panel space. Yokogawa ProSafe-RS provides SIL 3 with 1oo2D architecture; quad redundant configurations not available. The HIMA H51Q-H B5233-2 997235233 maintains unique market position as the only commercially available 1oo4D safety controller with TÜV SIL 3 certification and 20-year proof test interval. While Rockwell Automation GuardLogix 5580 offers enhanced diagnostics, it cannot match the HIMA H51Q-H B5233-2 997235233‘s fault tolerance and extended maintenance intervals. The HIMA H51Q-H B5233-2 997235233 represents the reference standard for applications where both safety integrity and operational availability are equally critical.

Selection Recommendations and Precautions

- Application Suitability: The HIMA H51Q-H B5233-2 997235233 is designed for maximum availability applications; for standard SIL 3 requirements without extreme fault tolerance needs, HIMA’s H41q or HIMax platforms provide cost-optimized alternatives. Consult HIMA application engineering for platform selection guidance.

- Firmware Compatibility: The HIMA H51Q-H B5233-2 997235233 requires specific firmware versions matched to system configuration; all four processor channels must maintain identical firmware revisions. Field firmware upgrades require HIMA service engineer authorization and specialized equipment.

- Redundancy Configuration: Quad redundant operation requires the HIMA H51Q-H B5233-2 997235233 installed in H51q-specific backplane with dedicated synchronization buses. Standard H51 backplanes do not support quad redundant communication between processor channels.

- Voting Logic Selection: Configure voting logic based on application safety requirements and availability targets; 2oo4D provides maximum safety integrity, 1oo4D provides maximum availability. The HIMA H51Q-H B5233-2 997235233 supports per-function voting configuration.

- Environmental Verification: Confirm installation environment meets specifications: -40°C to +70°C operating, 5-95% RH non-condensing, vibration <2g. The HIMA H51Q-H B5233-2 997235233 requires forced air cooling for installations above 50°C ambient.

- Spare Parts Strategy: The HIMA H51Q-H B5233-2 997235233 is manufactured to order with 20-26 week lead time; maintain minimum 100% spares inventory (one complete spare controller) for mission-critical installations. HIMA recommends spares reservation program for this high-value, long-lead item.

- Safety Manual Compliance: Complete review of HIMA H51q Safety Manual (HI 801 101 E) before configuration, installation, or maintenance. All work on HIMA H51Q-H B5233-2 997235233 must be performed by TÜV-certified functional safety engineers per IEC 61511 requirements.

- Proof Test Planning: Develop and document proof test procedures leveraging the HIMA H51Q-H B5233-2 997235233‘s 20-year interval; however, regulatory authorities may require more frequent demonstration. Consult applicable industry standards and local regulations.

- Cyber Security: The HIMA H51Q-H B5233-2 997235233 supports defense-in-depth security architecture; implement network segmentation, application whitelisting, and secure remote access per HIMA security guideline HI 802 311 E. Change default passwords prior to network connection.

- Obsolescence Management: HIMA commits to 15-year product lifecycle from introduction; the HIMA H51Q-H B5233-2 997235233 remains in active production with guaranteed spare parts availability. Engage HIMA lifecycle management services for long-term support agreements.

DS200DACAG1A GE PLC

DS200DCCAG4D GE PLC

DS200DCFBG1BI GE PLC

DS200DCPAG1A GE PLC

DS200DCVAG1A GE PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922