Description

Product Description

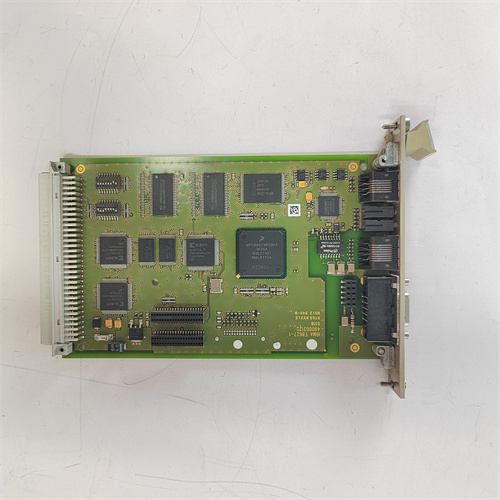

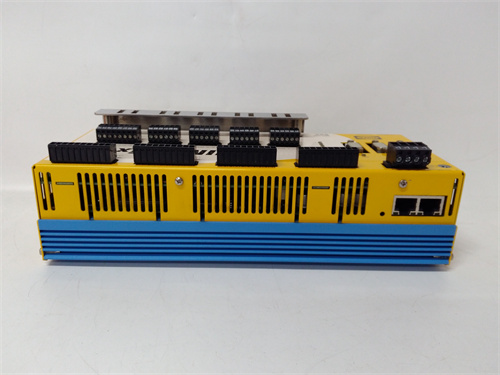

The HIMA F35, with the specific order code 982200416, is a central processing unit (CPU) module for the HIMA F3 series of safety programmable logic controllers (PLCs). This module serves as the core computing and logic-solving engine for Safety Instrumented Systems (SIS), engineered to execute certified safety logic with the highest levels of reliability and deterministic performance. The HIMA F35 CPU is designed to manage complex safety functions, process data from dedicated safety I/O modules, and implement fail-safe responses to bring industrial processes to a safe state.

Product Parameters

- Manufacturer / Brand: HIMA.

- Series: F3 Series Safety PLC.

- Model: F35 (Central Processing Unit).

- Order Code: 982200416.

- Safety Certification: TÜV-certified according to IEC 61508 for use in Safety Instrumented Systems up to SIL 3.

- Architecture: Designed with a redundant, self-testing internal structure (often dual-channel with comprehensive diagnostics) to detect internal faults and ensure fail-safe behavior.

- Processor: Features a high-performance safety microprocessor.

- Memory: Includes sufficient user memory for complex safety applications and integrated non-volatile memory for storing the safety program and parameters.

- Communication Ports: Equipped with multiple ports, including an engineering port (USB/Ethernet) for programming and a system port for peer-to-peer communication with other HIMA CPUs or integration with higher-level systems via protocols like Profinet, Modbus TCP, or OPC UA.

- I/O System Connectivity: Connects to the F3 series I/O modules via the high-speed, deterministic F-FactoryBus (FFB).

- Diagnostics: Comprehensive self-diagnostics and status indicators (LEDs) for power, run state, errors, and communication.

- Programming: Programmed using HIMA’s dedicated Safety Engineering Tool (Hi-Safe or similar), utilizing certified function blocks and languages like F-FBD (Function Block Diagram).

Advantages and Features

- High Safety Integrity: Provides a pre-certified hardware platform for SIL 3 applications, significantly reducing the effort and time required for system validation.

- Deterministic and Fast Execution: Offers predictable scan times and fast processing, which is critical for meeting the response time requirements of safety loops.

- Comprehensive Fault Detection: Extensive internal diagnostics continuously monitor the CPU’s health, ensuring that any detected fault leads to a defined safe state.

- Flexible Communication: Supports integration with various control systems and networks, allowing it to function as a standalone safety system or as an integrated part of a larger automation architecture.

- User-Friendly Engineering: The dedicated engineering software provides a library of pre-certified function blocks, simplifying the development of safety logic while maintaining compliance.

Application Cases in Industry

- Oil & Gas (Emergency Shutdown – ESD): The HIMA F35 CPU serves as the logic solver for a platform-wide ESD system, processing signals from emergency buttons and sensors to execute valve shutdown sequences.

- Chemical Processing (Reactor Protection): Manages complex interlocking and quenching sequences for batch reactors to prevent runaway reactions and over-pressurization.

- Power Generation (Burner Management – BMS): Implements the safety logic for boiler start-up, flame supervision, and master fuel trip in a burner management system.

- Rail Transportation (Interlocking Systems): Used in railway signaling systems to ensure the safe routing of trains and prevent collisions.

- Manufacturing (Press and Robot Safety): Provides safety functions for hazardous machinery, such as light curtain monitoring and safe stop functions for industrial presses and robotic cells.

Comparison with Competing Products

Direct competitors are safety CPUs from other dedicated safety system vendors, such as the Siemens SIMATIC S7-1500 F or the Rockwell Automation GuardLogix 5570. The HIMA F35 differentiates itself through its singular focus on functional safety and its heritage as an independent safety specialist. Compared to a safety-rated PLC from a general automation provider, the HIMA system is often perceived as a more “pure” safety controller, with a software toolchain and architecture dedicated solely to safety applications. While Siemens and Rockwell offer deep integration with their standard control platforms, HIMA’s strength is its independence, which can be advantageous for applications requiring clear separation between basic process control and safety systems.

Selection Suggestions and Precautions

- Selection Suggestions:

- Select the HIMA F35 CPU for designing a new, high-integrity Safety Instrumented System (SIS) or for modernizing an existing HIMA-based safety system.

- Assess the required program size, scan time performance, and communication needs of your safety application to ensure the F35 model is sufficient.

- Plan the overall system architecture, including the number and type of F3 I/O modules required, and ensure they are compatible with the CPU and the chosen rack.

- Precautions:

- Qualified Personnel Mandatory: Safety system design, programming, and maintenance must be performed by personnel trained and competent in functional safety standards (IEC 61511) and the HIMA toolset.

- Safety Lifecycle Compliance: The CPU is a component within a larger SIS. Its implementation must follow the full safety lifecycle, including hazard analysis, design, validation, installation, and ongoing proof testing.

- Software and Firmware Management: Use only the official HIMA Safety Engineering Tool and approved firmware versions. Unauthorized software or firmware modifications can invalidate the safety certification.

- Configuration Backup: Always maintain secure, version-controlled backups of the safety application program and hardware configuration. Loss of this data can lead to extensive re-engineering and re-validation.

- Genuine Parts and Support: Source the HIMA F35 using the exact order code 982200416 from authorized HIMA distributors. The use of non-genuine parts jeopardizes system certification and safety integrity. Ensure access to HIMA’s technical support for configuration and troubleshooting.

DSQC639 3HAC025097-001/11

1100-COD93

51401583-100

51401583-200 PLC

VGG-4422-U-A240 PLC

FDPS364R WESTINGHOUSE PLC

CS31ICSA04B5 PLC

P0951CE PC

9907-014 PLC

690-431450B0-B00W00-B400 PLC DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922