Description

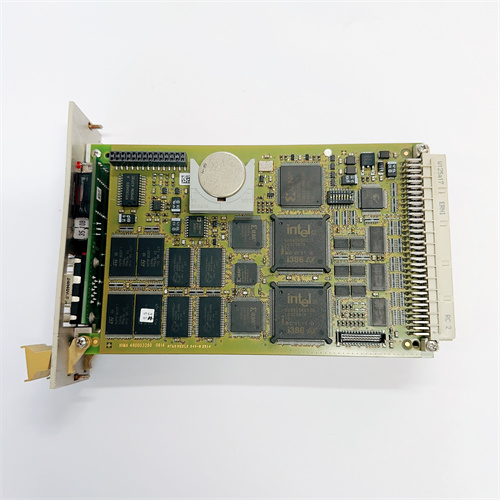

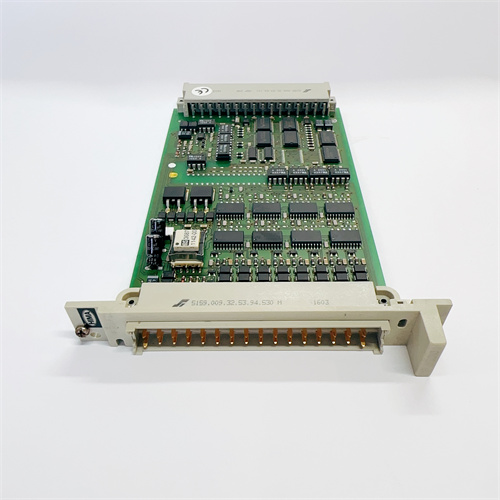

The HIMA F3330 984333002 is a high-performance safety-related digital output module, a core component of HIMA’s renowned HIMax and H41q/H51q safety systems, engineered to deliver uncompromising reliability and precision for industrial safety automation applications worldwide. As a SIL 3-certified safety module, the HIMA F3330 984333002 is designed to convert safety controller signals into actionable output commands for critical industrial actuators, ensuring fail-safe operation and compliance with the strictest global functional safety standards. What defines the HIMA F3330 984333002 is its robust fault-tolerant design, which eliminates single points of failure and guarantees continuous operation even in the event of internal component malfunctions—an essential trait for safety-critical industrial processes. Every unit of the HIMA F3330 984333002 is manufactured to HIMA’s rigorous quality standards, with industrial-grade components that withstand extreme temperature fluctuations, electrical noise, and mechanical vibration in harsh plant environments. The HIMA F3330 984333002 integrates seamlessly with HIMA’s full portfolio of safety controllers, input modules, and communication gateways, creating a unified safety automation ecosystem that streamlines system design, installation, and commissioning for plant engineers and integrators.

Product Parameters

- Brand & Model: HIMA F3330 984333002

- Product Type: Safety-Related Digital Output Module

- Functional Safety Rating: SIL 3 (per IEC 61508), AK 6 (per DIN V 19250), Category 4 (per EN ISO 13849-1)

- Number of Output Channels: 8 independent digital output channels

- Output Voltage Range: 24 V DC (18 – 30 V DC nominal)

- Output Current: 2 A per channel (continuous), 5 A per channel (inrush, 100 ms)

- Output Type: Electromechanical relays (normally open/normally closed configurable)

- Fault Detection: Redundant channel monitoring, short-circuit detection, overcurrent protection, module self-diagnosis

- Response Time: < 5 ms (signal transmission from controller to output)

- Operating Temperature: -40 °C to +70 °C (-40 °F to +158 °F)

- Storage Temperature: -40 °C to +85 °C (-40 °F to +185 °F)

- Power Supply: 24 V DC (powered via HIMA safety system backplane)

- Mounting: Rack-mount (HIMA HIMax/H41q/H51q system racks), DIN rail compatible

- Communication Interface: Backplane bus (HIMA proprietary safety bus)

- Certifications: ATEX, IECEx, UL, CSA, CE, DNV GL (for marine applications)

- Dimensions (W x H x D): 45 mm x 210 mm x 120 mm (1.77” x 8.27” x 4.72”)

Advantages and Features

- Industry-Leading Safety Certification: The HIMA F3330 984333002 holds SIL 3, AK 6, and Category 4 ratings, meeting the most stringent global functional safety standards for safety-critical industrial processes, eliminating compliance risks for end-users.

- Redundant Fault-Tolerant Design: Equipped with dual internal circuits and real-time self-diagnosis, the module detects faults instantaneously and switches to fail-safe mode, eliminating single points of failure and ensuring uninterrupted safety operation.

- High Channel Density & Flexibility: 8 independent configurable output channels (NO/NC) deliver high spatial efficiency in control cabinets, while adjustable current ratings support a wide range of actuators (valves, motors, emergency stops) without additional hardware.

- Ultra-Fast Response Time: A < 5 ms signal response time ensures the HIMA F3330 984333002 triggers critical safety actions (e.g., emergency shutdowns) in milliseconds, minimizing the risk of equipment damage or human harm in fault scenarios.

- Seamless HIMA Ecosystem Integration: As a native component of HIMA’s HIMax and H41q/H51q safety systems, the module plug-and-plays with HIMA controllers and input modules, reducing configuration time and eliminating compatibility issues with third-party hardware.

- Rugged Industrial Construction: Industrial-grade relays and corrosion-resistant components enable the HIMA F3330 984333002 to operate in extreme temperatures, high vibration, and electrical noise—ideal for oil & gas, chemical, and power generation environments.

- Comprehensive Fault Protection: Built-in short-circuit, overcurrent, and reverse polarity protection safeguards the module and connected actuators from electrical damage, reducing maintenance costs and extending service life.

- Global Compliance & Certification: A full suite of international certifications (ATEX, IECEx, UL, DNV GL) makes the module suitable for deployment in all global industrial markets, including hazardous areas and marine applications.

- Hot-Swappable Capability: The HIMA F3330 984333002 supports hot-swapping in HIMA safety racks, allowing module replacement without powering down the entire safety system—minimizing process downtime during maintenance.

Application Fields & Application Cases

Core Application Fields

The HIMA F3330 984333002 is engineered for safety-critical industrial automation processes where unplanned safety system failure poses severe risks to personnel, equipment, and the environment. It is a staple component in the oil & gas, petrochemical, chemical, power generation, pharmaceutical, and marine industries, deployed to control emergency shutdown (ESD) systems, fire & gas (F&G) protection systems, and interlock systems for key equipment including:

- Pressure/vacuum relief valves

- Emergency shutdown valves (ESVs)

- Pump/motor emergency stops

- Burner management systems (BMS)

- Tank overfill protection systems

- Hazardous area ventilation controls

- Nuclear power plant auxiliary safety systems

Real-World Application Cases

- Oil & Gas (Onshore Refinery, Europe): A major European petroleum refinery integrated the HIMA F3330 984333002 into its ESD system for crude distillation units, controlling 8 emergency shutdown valves per module. The module’s SIL 3 rating and fast response time enabled the refinery to meet EU functional safety regulations, while hot-swappable capability reduced maintenance downtime by 90% during scheduled system checks.

- Petrochemical (Chemical Plant, Middle East): A petrochemical plant in the Middle East deployed the HIMA F3330 984333002 as part of a fire & gas protection system for ethylene production units. The module’s rugged design withstood extreme ambient temperatures (up to 65 °C) and electrical noise from nearby compressors, triggering automatic ventilation and fuel shutoff within 3 ms of a gas leak detection—preventing a potential explosion.

- Power Generation (Combined Cycle Power Plant, Asia): A 1.5 GW combined cycle power plant used the HIMA F3330 984333002 to control interlock systems for gas turbines and heat recovery steam generators (HRSGs). The module’s fault-tolerant design prevented a single channel failure from triggering an unnecessary plant shutdown, preserving continuous power generation and avoiding $1.2M in lost revenue from unplanned downtime.

- Marine (LNG Carrier, Global): A leading LNG carrier operator installed the HIMA F3330 984333002 in the ship’s cargo handling safety system, controlling emergency isolation valves for LNG storage tanks. The module’s DNV GL marine certification and resistance to saltwater corrosion ensured reliable operation in the marine environment, while its fail-safe design prevented tank overpressure and potential LNG leaks during transoceanic voyages.

- Pharmaceutical (Batch Production Plant, North America): A pharmaceutical plant used the HIMA F3330 984333002 in its clean room process safety interlock system, controlling emergency stops for sterile production lines. The module’s compact design saved valuable space in clean room control cabinets, and its low electromagnetic interference (EMI) avoided disruption to sensitive lab equipment nearby.

Comparison with Competing Products

The HIMA F3330 984333002 outperforms key competitors in the safety digital output module market (including Siemens S7 F-series, Allen-Bradley GuardLogix, and Phoenix Contact PSR series) across core performance, safety, and usability metrics, making it the gold standard for safety-critical industrial applications.

| Comparison Metric | HIMA F3330 984333002 | Competitor Products (General) |

|---|---|---|

| Functional Safety Rating | SIL 3 / AK 6 / Category 4 (highest global ratings) | SIL 2/SIL 3 (variable); limited AK 6 compliance |

| Response Time | < 5 ms | 10 – 20 ms (most models) |

| Operating Temperature | -40 °C to +70 °C | -20 °C to +60 °C (narrow range) |

| Fault Detection | Redundant channel monitoring + full module self-diagnosis | Basic channel fault detection; no real-time self-diagnosis |

| Hot-Swappable | Yes (HIMA system racks) | No (requires system shutdown for replacement) |

| Channel Current | 2 A continuous / 5 A inrush | 1 A continuous / 3 A inrush (standard) |

| Hazardous Area Certifications | ATEX/IECEx for Zone 0/1/2 | ATEX/IECEx for Zone 1/2 only (most models) |

| Total Cost of Ownership | Low maintenance; 15+ year service life; hot-swappable reduces downtime | Higher maintenance; 8–10 year service life; system shutdowns for replacement increase downtime costs |

Additional competitive advantages: The HIMA F3330 984333002 is backed by HIMA’s 60+ years of expertise in functional safety, with a global technical support network offering 24/7 remote troubleshooting and on-site service— a benefit many competitors lack. Unlike third-party modules that require custom programming for integration with HIMA safety systems, the HIMA F3330 984333002 is a native component, eliminating integration costs and reducing commissioning time by up to 50%.

Selection Suggestions

- Align with Safety Requirements: Select the HIMA F3330 984333002 for processes requiring SIL 3/AK 6/Category 4 safety ratings (e.g., ESD, F&G systems); it is the optimal choice for high-risk industrial applications where compliance with the strictest safety standards is mandatory.

- HIMA Ecosystem Compatibility: Prioritize the module if your facility already uses HIMA HIMax, H41q, or H51q safety controllers—its native integration eliminates compatibility issues and streamlines system design and commissioning.

- Operating Environment Consideration: Choose the HIMA F3330 984333002 for facilities with extreme operating conditions (subzero temperatures, high heat, electrical noise, vibration) or hazardous areas (ATEX/IECEx Zones 0/1/2), as its rugged design outperforms competitor modules in these environments.

- Process Downtime Sensitivity: Opt for the module if your process cannot tolerate unplanned shutdowns for maintenance—its hot-swappable capability allows module replacement without powering down the safety system, minimizing production downtime.

- Actuator Load Requirements: Select the HIMA F3330 984333002 for controlling high-current actuators (2 A continuous) such as large valves and motors, as competitor modules typically offer only 1 A continuous current per channel (requiring additional power relays).

- Global Deployment Planning: Choose the module for international plant projects, as its full suite of global certifications (ATEX, IECEx, UL, DNV GL) eliminates the need for region-specific hardware modifications.

Precautions

- Certified Installation: The HIMA F3330 984333002 must be installed by a HIMA-certified safety system engineer; improper installation (e.g., incorrect wiring, rack mounting) will compromise safety performance and void the manufacturer’s warranty.

- Power Supply Compliance: Power the module only via the HIMA safety system backplane (24 V DC); do not connect external power supplies, as this will cause internal component damage and fault detection errors.

- Wiring Best Practices: Use shielded twisted-pair cable for output wiring to minimize electrical noise and interference; ensure proper grounding (per HIMA installation guidelines) to prevent signal degradation and false fault alerts.

- Channel Loading Limits: Do not exceed the 2 A continuous/5 A inrush current rating per channel; overloading channels will burn out internal relays and cause permanent module damage.

- Hazardous Area Installation: When installing the HIMA F3330 984333002 in ATEX/IECEx hazardous areas, follow the manufacturer’s explosion-proof installation guidelines and use only HIMA-approved accessories (cable glands, enclosures) to maintain certification compliance.

- Firmware & Software Updates: Only update the module’s firmware and associated HIMA safety system software with official HIMA releases; unapproved third-party firmware will cause system incompatibility and safety failures.

- Hot-Swap Procedure: When hot-swapping the HIMA F3330 984333002, follow HIMA’s step-by-step procedure to ensure the safety system remains in fail-safe mode during replacement; improper hot-swapping may trigger an unintended process shutdown.

- Spare Parts Management: Maintain at least one spare HIMA F3330 984333002 module for safety-critical production lines; HIMA’s global spare parts network ensures fast delivery, but advance stockpiling minimizes downtime in the event of module failure.

- Regular Testing: Perform monthly functional tests of the module’s output channels and fault detection capabilities (per HIMA’s recommended maintenance schedule) to verify proper operation—untested faults may lead to safety system failure in critical scenarios.

- Environmental Protection: Mount the HIMA F3330 984333002 in a sealed control cabinet to protect against dust, moisture, and chemical exposure; avoid direct installation in process areas with corrosive fumes or heavy dust.

IS200ECTBG2A GE

IS200EDCFG1A GE

IS200EDCFG1B GE

IS200EDFFH3A GE

IS200EGDMH GE PLC

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922