Description

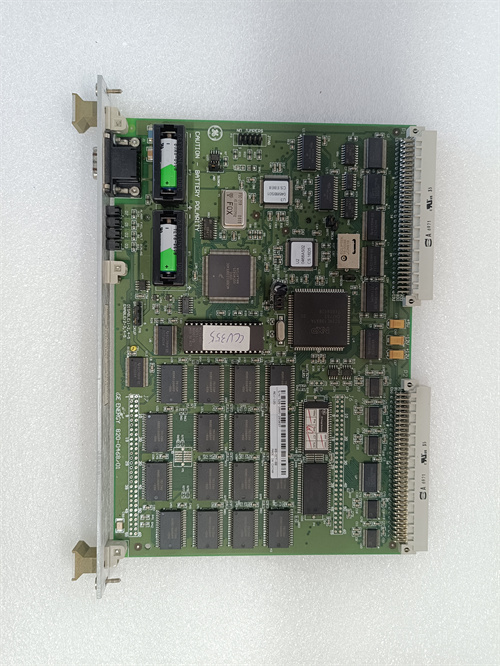

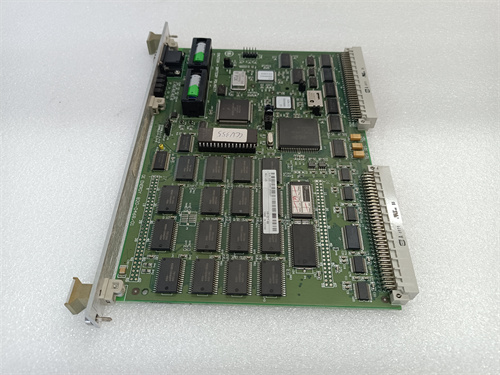

Product Description

The GE WESDAC D20A is a legacy, microprocessor-based Remote Terminal Unit (RTU) from General Electric’s WESDAC product line, designed for supervisory control and data acquisition (SCADA) systems in geographically distributed industries. This unit functions as an intelligent field data concentrator and controller, installed at remote sites such as electrical substations, pipeline block valves, or water pumping stations. The primary function of the GE WESDAC D20A is to acquire data from field instruments (status, analog values), execute local control logic, and communicate this information to a central master station via various communication links. It also acts on commands received from the master, such as opening or closing a valve or breaker. As a foundational component of early distributed control networks, the D20A RTU provided the critical link between centralized operators and far-flung assets, enabling remote monitoring and control long before modern networking was commonplace.

Technical Parameters and Features

- Device Type: Microprocessor-Based Remote Terminal Unit (RTU).

- Architecture: Modular design, typically consisting of a central processor module, power supply, and various plug-in I/O modules (digital input, analog input, digital output/counter, communication).

- Processing: Features an early-generation microprocessor (e.g., Motorola 68000 series) capable of executing ladder logic or proprietary control programs stored in non-volatile memory.

- Input/Output (I/O): Supports a range of I/O modules for:

- Digital Input (DI): Status points (breaker position, alarm contacts).

- Analog Input (AI): 4-20 mA or voltage signals from transducers (pressure, flow, temperature).

- Digital Output/Counter (DO/CT): Control relays and pulse accumulation.

- Communication: Equipped with multiple serial communication ports supporting legacy protocols essential for SCADA, such as:

- DNP3.0 (Distributed Network Protocol) – A very common protocol for utility SCADA.

- Modbus RTU/ASCII.

- GE’s proprietary protocols (e.g., MEGATEC, CDC 8969).

- Links could be over leased line, radio, or early dial-up modem.

- Power Supply: Designed for harsh field environments, often accepting a wide range of DC or AC input voltages.

- Environmental Rating: Typically housed in a rugged, wall-mount or rack-mount enclosure suitable for outdoor or industrial cabinet installation.

Advantages and Key Features

- Ruggedized for Harsh Environments: The GE WESDAC D20A was engineered for reliability in unattended remote sites, with robust construction and wide operating temperature ranges, making it a workhorse for utility and pipeline applications.

- True Distributed Intelligence: Unlike simple remote I/O, it could execute autonomous control logic (e.g., interlock sequences, PID loops) locally, reducing dependency on constant communication with the master and improving response time for local events.

- Standard Protocol Pioneer: Its support for DNP3.0 made it a key player in standardizing utility SCADA communications, providing features like report-by-exception, time-stamped events, and data integrity checks that were advanced for its time.

- Modular and Configurable: The modular I/O system allowed users to tailor the D20A RTU’s point count and types to the exact needs of each remote site, from a few dozen to several hundred points.

- Long Service Life and Proven Track Record: These units have demonstrated exceptional longevity, with many still in operation decades later, a testament to their build quality and the critical nature of the infrastructure they monitor.

Application Case Studies in Various Fields

- Electrical Transmission & Distribution: Installed in a remote 69kV substation, the GE WESDAC D20A monitors breaker status, transformer temperatures, and line voltages, reporting to the utility’s EMS/SCADA master and executing automatic capacitor bank switching based on voltage levels.

- Oil & Gas Pipeline SCADA: Used at a block valve site along a crude oil pipeline. It monitors pipeline pressure, controls the block valve actuator, and detects leaks via pressure rate-of-change calculations, communicating alarms via satellite link.

- Water/Wastewater Distribution: Sits at a remote well field or booster pump station, monitoring pump status, discharge pressure, and tank levels, and providing local pump alternation control.

- Mining Operations: Monitors critical parameters like water levels in sumps, conveyor belt status, and ventilation fan operation in remote areas of a mine site.

Comparison with Competing Products

In its era, the GE WESDAC D20A competed with RTUs from manufacturers like Motorola (MOSCAD), S&C Electric, and Schlumberger. Compared to modern programmable logic controllers (PLCs) or newer RTUs:

- Purpose-Built for SCADA vs. General-Purpose: The D20A was designed from the ground up as a communications-centric RTU with robust protocols like DNP3.0 at its core. A modern PLC can function as an RTU but often requires additional protocol converters and configuration to match the native, optimized SCADA functionality of the WESDAC system.

- Legacy Architecture vs. Modern IT Integration: Its architecture reflects late-20th-century technology. While extremely reliable, it lacks the Ethernet connectivity, web servers, and cybersecurity features expected in modern “IIoT-ready” RTUs or PACs.

- Proprietary vs. Open Systems: Configuration was done with specialized, proprietary tools. Modern systems tend to use more open programming standards (IEC 61131-3). The D20A‘s value today is largely in maintaining existing, working installations.

Selection Advice and Important Notes

- Legacy System Support Only: The GE WESDAC D20A should be selected almost exclusively for spare parts, like-for-like replacement, or minor expansion of an existing, functioning WESDAC system. It is not a choice for new greenfield projects.

- Scarcity of New Units and Expertise: New units are likely unavailable. Sourcing may be limited to refurbished units or the aftermarket. Furthermore, engineering expertise and spare parts for these legacy systems are becoming increasingly rare.

- Migration Planning is Critical: Users with installed D20A bases should have an active migration plan to modern platforms (e.g., GE D400, Schneider Electric Telvent, or other modern RTUs). This plan should address hardware lifecycle, cybersecurity vulnerabilities, and finding replacement engineering talent.

- Verify Firmware and Protocol Compatibility: If integrating a spare or additional D20A into an existing network, ensure the firmware version and protocol configurations (DNP3 addresses, point maps) are exactly compatible to avoid communication failures.

- Documentation is Key: Preserve all configuration files, wiring diagrams, and communication settings. This documentation is invaluable for troubleshooting and eventual migration, as the tools to extract this information from the unit may no longer be readily available.

57C330C

JW3250F250A-250-690VAC

6ES7133-1BL11-0XB0

P0922AE

MDFKABS090-22

DEIFFAS-113DG

6ES7315-6FF04-0AB0 CPU

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922