Description

Product Description

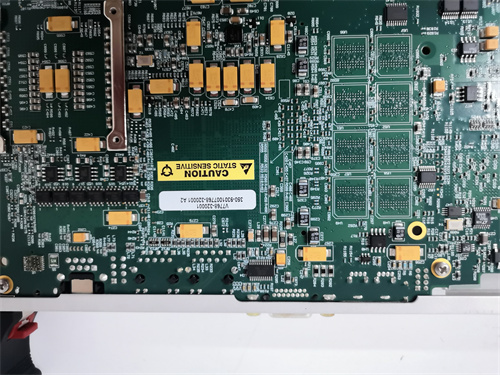

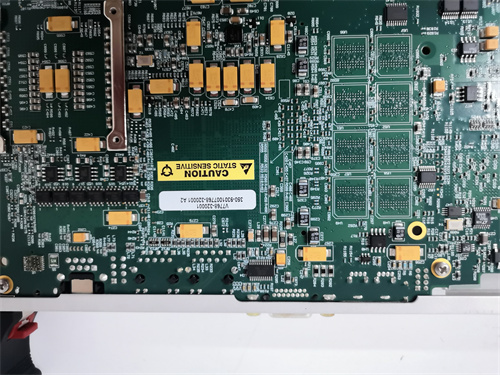

The GE V7668A-131000 (alternatively listed under part number 350-931000-7668-131000 B) is a specialized Input/Output (I/O) module from GE’s legacy industrial automation portfolio, specifically designed for high-performance or distributed control systems such as the GE Genius® I/O or VMIC product lines. This module serves as an intelligent interface block that connects field devices—sensors and actuators—to a central or distributed controller via a high-speed proprietary bus. The core function of the GE V7668A-131000 is to provide signal conditioning, electrical isolation, and data conversion for a specific set of analog or discrete signals, communicating this processed data bi-directionally with the main PLC or control system. Often part of a rugged, modular I/O rack system, the reliability and deterministic performance of the V7668A-131000 module are crucial for real-time control applications in demanding environments. Its dual part numbers indicate variations in manufacturing or packaging revisions, but refer to the same core functional hardware.

Product Parameters

- Model: V7668A-131000

- Alternate Part Number: 350-931000-7668-131000 B

- System Family: Likely part of GE Genius I/O, VMIC, or a similar distributed I/O system.

- Module Type: Specific I/O function (e.g., Analog Input, Analog Output, Discrete, or Specialty). The “131000” suffix often indicates a specific configuration or terminal type.

- Channel Count: Varies by exact function; common configurations include 8 or 16 channels for discrete I/O, or fewer channels (e.g., 4, 8) for analog I/O.

- Signal Type: Depending on variant:

- Analog: Could be 4-20mA input/output, ±10V input, thermocouple/RTD input.

- Discrete: 24 VDC sinking/sourcing input or output, 120 VAC input, relay output.

- Isolation: Channel-to-channel and/or channel-to-bus isolation for noise immunity and safety.

- Communications: Interfaces via a dedicated bus connector (e.g., Genius bus, VMIC bus) to a bus controller module or directly to a compatible CPU.

- Diagnostics: Features status LEDs for power, communication, and channel faults.

Advantages and Features

- Distributed Intelligence: As part of systems like Genius I/O, the GE V7668A-131000 allows for placement of I/O close to field devices, reducing long wiring runs, saving cost, and improving signal integrity.

- Robust Industrial Design: Housed in a rugged metal or high-grade plastic enclosure, it is built to withstand harsh conditions including temperature extremes, vibration, and electrical noise.

- Deterministic Performance: Communicates over a deterministic fieldbus, ensuring predictable scan times and reliable real-time control, which is superior to non-deterministic networks for critical loops.

- Simplified Maintenance: Modules are typically hot-swappable (with system precautions), allowing for replacement without shutting down the entire process, thereby increasing system availability.

- Integrated Diagnostics: Provides clear local and remote diagnostic information, enabling rapid fault identification and troubleshooting to minimize downtime.

Application Cases in Application Fields

This module is found in continuous process and discrete manufacturing industries with demanding control needs:

- Automotive Manufacturing: Used in distributed I/O racks controlling welding robots, paint shop conveyors, and assembly line tooling, where reliability is critical.

- Food and Beverage Processing: Controls valves, pumps, and temperature zones in batch processing, with its rugged design resisting washdown environments.

- Water/Wastewater Treatment: Distributed along filter beds, clarifiers, and chemical dosing stations to monitor levels, pressures, and control pumps and valves.

- Material Handling: Integrated into systems controlling high-speed sortation conveyors, automated storage and retrieval systems (AS/RS), and palletizers.

- Pharmaceutical Production: Provides precise analog control for mixing vessels and environmental monitoring in cleanrooms.

Comparisons with Competing Products

- Vs. Siemens ET 200S/200SP Distributed I/O: Siemens’ PROFINET-based systems are a major competitor. The GE V7668A-131000, if part of the Genius system, uses a GE-proprietary bus. The choice is heavily influenced by the existing control system architecture (GE vs. Siemens PLCs).

- Vs. Allen-Bradley POINT I/O or FLEX I/O: Rockwell’s distributed I/O platforms offer similar functionality. The GE V7668A-131000 is comparable in ruggedness and purpose. Selection typically depends on whether the site standard is GE or Allen-Bradley.

- Vs. Standard PLC Rack I/O: Unlike a card in a central PLC rack, a distributed module like the V7668A-131000 reduces control cabinet size and field wiring. However, it requires a network infrastructure (bus cabling) and a bus controller.

- Vs. Modern Ethernet-based I/O (e.g., Profinet, EtherNet/IP): Legacy bus modules like this offer proven determinism but lack the IT integration, higher bandwidth, and device-level diagnostics of modern industrial Ethernet protocols. They represent a mature, stable technology.

Selection Suggestions and Precautions

- Precise Identification is Critical: The exact functionality (Analog Input, Digital Output, etc.) must be confirmed by cross-referencing both part numbers (V7668A-131000 and 350-931000-7668-131000 B) with GE’s official technical documentation or a reputable supplier’s database. A mismatch will cause system failure.

- Confirm System Compatibility: This module is not universal. It must be compatible with the specific I/O rack, bus controller, and main PLC CPU (e.g., Series 90-70, RX3i) in your system. Verify compatibility with the host system’s firmware.

- Bus Termination and Configuration: Distributed I/O systems require proper bus termination and unique node addresses. Ensure the module’s address is correctly set via DIP switches or software and that the bus is correctly terminated.

- Legacy Product Status: This is likely a legacy product. Verify availability of spares and ensure you have access to configuration software (e.g., Proficy Machine Edition Logic Developer) and documentation for support.

- Observe Safety Procedures: Even if hot-swappable, always follow proper lock-out/tag-out (LOTO) procedures and safety guidelines when installing or replacing modules in a live system to prevent injury or process disruption.

8200-226 WoodWard PLC

8440-1706 WoodWard

9907-167 WoodWard

5446-348 WoodWard PLC

9907-005 WoodWard PLC

9905-797 WoodWard PLC

5464-545 WoodWard PLC

5466-341 WoodWard

5466-329 WoodWard

5466-346 WoodWard

5464-843 WoodWard PLC

5466-355 WoodWard PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922