Description

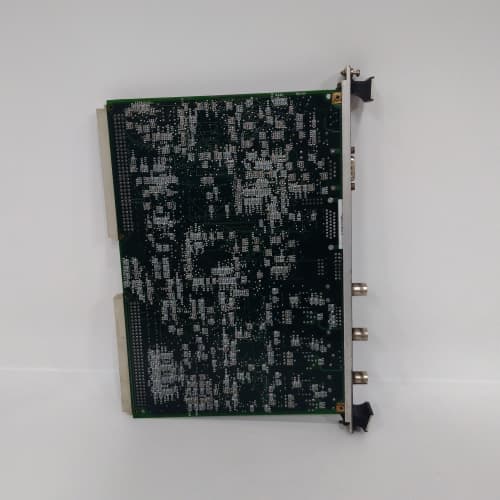

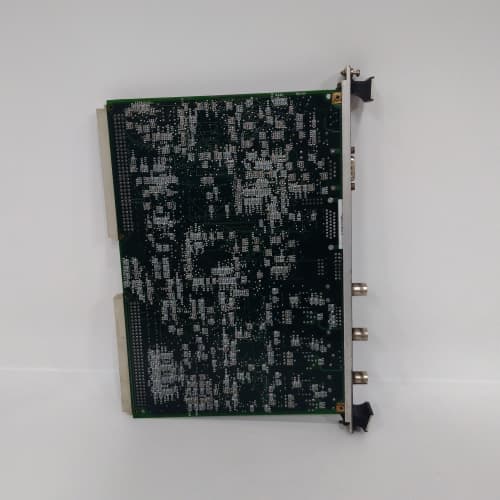

Product Description

The GE IS215VAMBH1A is a Vibration Analog Monitor Board designed for the GE Mark VIeS series, a critical component in the protection and monitoring system for industrial turbines and rotating machinery. This specialized module is responsible for continuously monitoring and conditioning vibration signals from proximity probes, accelerometers, and other transducers to safeguard equipment from mechanical damage. The primary role of the GE IS215VAMBH1A is to accept raw analog signals from vibration sensors, perform essential signal processing such as filtering and integration (e.g., converting acceleration to velocity), and transmit precise, conditioned data to the turbine control system for alarming, trending, and protective trips. For reliability engineers and control specialists, the accuracy and integrity of the IS215VAMBH1A are non-negotiable for predictive maintenance and catastrophic failure prevention.

Product Parameters/Key Specifications

- Manufacturer: GE Industrial Systems (General Electric)

- Series: Mark VIeS (Secure) Turbine Control & Protection System

- Function: Vibration Analog Monitor Board (Vibration Signal Conditioner/Interface)

- Input Channels: Typically provides multiple (e.g., 4, 8, or 16) isolated analog input channels dedicated to vibration signals.

- Supported Sensor Types:

- Proximity Probes (Eddy Current): For measuring shaft relative vibration and position (Keyphasor®).

- Velocity Seismoprobes: For measuring casing/bearing absolute vibration.

- Accelerometers: With optional integration to velocity/displacement.

- Signal Conditioning: Includes per-channel programmable features such as:

- Input signal filtering (high-pass, low-pass)

- Integration (for accelerometers)

- Demodulation (for proximity probes)

- Gap voltage adjustment for eddy current probes

- Output Signals: Provides conditioned, scaled analog outputs (e.g., 4-20mA or ±10VDC) representing vibration parameters (peak-to-peak, RMS) for connection to the main control system’s analog input modules.

- Power Supply: Powered from the Mark VIeS rack backplane.

- Diagnostics: Includes onboard diagnostics for channel health, sensor fault detection (e.g., probe gap, broken wire), and module status.

Advantages and Key Features

- High-Fidelity Signal Conditioning: Provides precise, low-noise conditioning specifically tuned for dynamic vibration signals, ensuring accurate measurement for both protection and analysis.

- Flexible Channel Configuration: Each channel can typically be independently configured for different sensor types and measurement parameters, offering great versatility within a single module.

- Integrated Sensor Diagnostics: Continuously monitors sensor health, providing early warning for conditions like probe deterioration, cable faults, or loss of signal—critical for maintaining protection system integrity.

- Secure Platform Integration: As part of the Mark VIeS series, it benefits from the platform’s enhanced cybersecurity features, protecting the critical vibration monitoring infrastructure from digital threats.

- Robust Electrical Isolation: Channels are isolated from each other and from the system to prevent ground loops and cross-talk, which is essential for accurate multi-channel vibration monitoring.

- Seamless System Interface: The conditioned analog outputs are designed for direct connection to the Mark VIeS control system, enabling easy integration of vibration data into control logic, HMIs, and historical archives.

Application Cases in Industry

The IS215VAMBH1A is deployed in any application where continuous vibration monitoring of critical turbomachinery is required.

- Gas & Steam Turbine Protection: Monitors shaft vibration (via proximity probes on bearings) and casing vibration to provide alarms and initiate trips through the turbine control system, preventing catastrophic blade or bearing failure.

- Compressor and Pump Monitoring: Used in pipeline compressor stations, refinery centrifugal compressors, and large boiler feed pumps to detect imbalances, misalignment, and bearing defects.

- Generator and Large Motor Monitoring: Protects critical auxiliary motors and the main generator by monitoring bearing vibration.

- Predictive Maintenance Programs: Provides high-quality, conditioned vibration data that can be used for trend analysis and frequency spectrum diagnostics to schedule maintenance before failures occur.

Comparison with Competing Products

- Vs. Dedicated Machinery Protection Systems (Bently Nevada, Emerson): Standalone systems like Bently Nevada 3500 offer specialized vibration monitoring with dedicated panel displays. The GE IS215VAMBH1A integrates vibration monitoring directly into the turbine control system (Mark VIeS), offering a more unified control and protection architecture, though sometimes with less dedicated vibration analysis depth.

- Vs. General-Purpose Analog Input (AI) Modules: A standard AI module cannot properly condition raw vibration signals. It lacks the necessary filtering, integration, sensor power (for proximity probes), and dedicated diagnostics. Using an AI module for vibration would result in poor data quality and no sensor health monitoring.

- Vs. Older GE Vibration Cards (Mark V/VI): The IS215VAMBH1A is designed for the modern, secure Mark VIeS platform, offering improved processing, better diagnostics, and cybersecurity features not present in legacy vibration interface cards.

- Internal GE Variants: Different suffixes in the model number indicate specific channel counts or firmware versions. The IS215VAMBH1A must be matched to the system’s requirements and software configuration.

Selection Suggestions and Precautions

- Match Sensor Specifications Precisely: Verify the compatibility of your vibration probes and transducers (output type, sensitivity, required power) with the IS215VAMBH1A‘s input channels. Incorrect matching will yield inaccurate readings.

- Proper Configuration is Critical: Each channel must be meticulously configured in the ToolboxST software for the correct sensor type, measurement units (mils, mm/s, g’s), scaling, and alarm setpoints. Incorrect configuration is a common source of failure.

- Follow Strict Wiring Practices: Use double-shielded, twisted-pair cables specifically designed for vibration signals. Ground the shield at the IS215VAMBH1A end only to prevent ground loops. Keep vibration cables separate from power cables.

- Calibration and Verification: After installation, verify the system’s accuracy by using a portable calibrator to inject known vibration signals and confirm the readings in the control system HMI match.

- Understand the Safety/Protection Architecture: Determine how the vibration alarms and trips from this module are integrated into the machine’s overall protection logic (e.g., 2-out-of-2 voting). Do not bypass diagnostics or alarms.

- Source Authentic Components: Given its critical role in machinery protection, always source the IS215VAMBH1A from authorized GE distributors. This ensures you receive a genuine module with the correct firmware and calibration, which is essential for reliable and safe operation.

1771-NR/C PLC

3500/22-01-01-00 PLC

GP2301-LG41-24V PLC

3500/22M

KUBOTAKF-C1000 PLC

0-48680-211 PLC

A06B-6057-H006

CP451-10S2

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922