Description

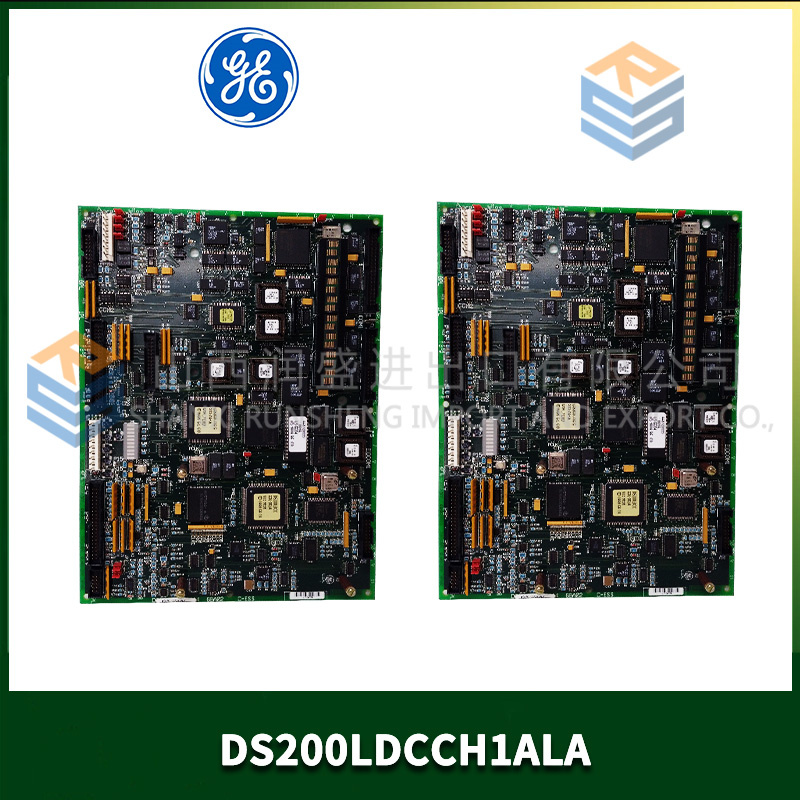

Product Description

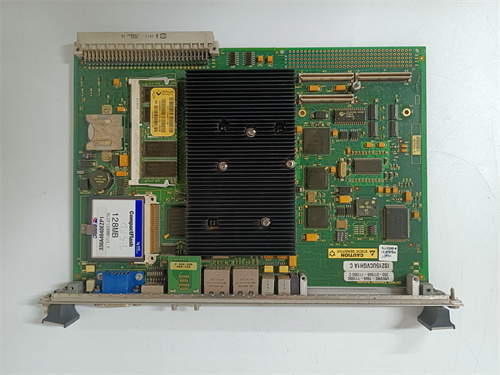

The GE IS215UCVGH1A is a specialized control module from the Mark VIe Speedtronic series, designed to function as a critical I/O pack, likely for high-speed or specialized control functions such as valve control or sequencing. This module operates as a distributed node within the Mark VIe system’s deterministic Ethernet network, executing localized control logic or managing a dedicated cluster of I/O points. The IS215UCVGH1A enhances system architecture by distributing processing power closer to the field devices, which improves response times and reduces the wiring burden on the main controller. Its design emphasizes deterministic performance and ruggedness for installation in challenging industrial environments. For comprehensive configuration guides, application notes, and technical specifications for this advanced I/O pack, please visit the official product link: GE IS215UCVGH1A. The strategic deployment of the GE IS215UCVGH1A is key to building scalable, high-performance, and responsive turbine control systems.

Product Parameters

- Manufacturer / Brand: GE (General Electric)

- Product Model: IS215UCVGH1A

- Product Series: Mark VIe Speedtronic Turbine Control System

- Module Type: Distributed I/O Pack or Specialized Control Module (e.g., Valve Control Pack, Sequencer)

- Primary Function: Provides localized processing and I/O interfacing for a specific control function; likely houses a dedicated processor, digital/analog I/O channels, and communication interfaces.

- Processing Capability: Contains an onboard processor for executing fast, dedicated control loops (e.g., valve positioning algorithms) or logic sequences independent of the main controller.

- I/O Complement: Includes a mix of digital and analog input/output channels specific to its application, such as inputs for valve position feedback (LVDT/RVDT) and outputs for servo driver commands.

- Communication Interface: Connects to the Mark VIe control network via a high-speed, deterministic Ethernet link (e.g., 100Base-TX) for synchronization and data exchange with the main controller.

- Environmental Rating: Typically designed for a harsh industrial environment with an extended operating temperature range.

Advantages and Features

The GE IS215UCVGH1A distributed module offers significant system design advantages:

- Distributed Control Intelligence: Offloads time-critical control tasks from the main controller, allowing for faster, more deterministic loop execution (e.g., sub-millisecond valve control) and reducing the computational load on the central CPU.

- Reduced Wiring and Cost: By placing I/O and processing close to a cluster of field devices (like a valve manifold), it dramatically reduces the amount of long-run analog and feedback cabling back to the main control room.

- Enhanced System Scalability and Modularity: Allows the control system to be expanded in a modular fashion by adding dedicated packs for new functions without major re-engineering of the main controller.

- Improved Diagnostics and Availability: Provides localized diagnostics for its dedicated function. A fault in one pack does not necessarily compromise the entire controller, enhancing overall system availability.

- Application-Optimized Design: The hardware and firmware of the IS215UCVGH1A are specifically tailored for its intended control function, providing higher performance and reliability than a generalized I/O module.

Application Cases in Application Fields

This module is deployed for dedicated, high-performance control loops in turbine systems:

- Gas Turbine Fuel Valve Control: Functions as a dedicated servo controller for the precise, fast positioning of main fuel gas control valves or liquid fuel divider valves, critical for combustion dynamics and load response.

- Compressor Inlet Guide Vane (IGV) Actuation: Manages the closed-loop control of IGVs, optimizing compressor efficiency and surge margin across the operating envelope.

- Steam Turbine Governor Valve Control: Serves as a high-speed electro-hydraulic controller (EHC) interface, providing the precise output to servo valves that position steam control valves.

- Turbine Bypass Valve Control: Controls large bypass valves with fast actuation requirements for safe start-up, shutdown, and load rejection scenarios.

- Sequential Auxiliary Control: Manages complex start-up or shutdown sequences for dedicated subsystems, such as a lube oil console or hydraulic power unit.

Comparisons with Competing Products

As an application-specific distributed module, comparisons are nuanced:

- vs. Centralized I/O in Main Rack: The IS215UCVGH1A offers superior performance for dedicated fast loops by eliminating network delays to the main CPU and providing specialized hardware. Centralized I/O is more general-purpose but may not meet the speed requirements for valve control.

- vs. Generic Programmable Drives/Controllers: While a generic servo drive could position a valve, the IS215UCVGH1A is pre-engineered for seamless integration with the Mark VIe ecosystem, including unified configuration tools, diagnostics, and synchronization with turbine protection logic.

- vs. Competing OEM Solutions: Similar distributed control packs exist in other turbine control platforms (e.g., Siemens T3000). The IS215UCVGH1A is differentiated by its use of GE’s network protocols, its configuration within ToolboxST, and its specific functional algorithms tuned for GE’s turbine applications.

Selection Suggestions and Precautions

- Confirm Specific Application Function: It is crucial to verify the exact application of the IS215UCVGH1A in your system (e.g., Fuel Valve Controller #1). Its configuration and firmware are specific to that role and are not universally interchangeable.

- Validate Firmware and Configuration Compatibility: The module’s firmware and application configuration must be compatible with the version of the main Mark VIe controller and system software. A mismatch will prevent communication or proper function.

- Source from Authorized Technical Channels: This is a sophisticated, firmware-dependent component. Procure the GE IS215UCVGH1A only from GE or authorized distributors who can supply the correct hardware revision, firmware, and configuration file. A generic hardware unit is useless without the correct software load.

- Plan for Network Integration: Installation requires careful integration into the existing deterministic Ethernet network topology. Document IP addresses, network switches used, and synchronization settings before replacement.

- Perform Comprehensive Loop Testing: After installation and software download, the control loop must be meticulously tested. This includes calibration of feedback sensors (LVDT), characterization of the actuator response, and verification of the control algorithm’s performance under simulation before connecting to the live process.

LTS350D PLC

1FK7042-5AF71-1SB0 PLC

Agilent-E1501A

IPPC-9150T-T PLC

MVI56-MCM

ACS-BRK-D

1771-ACNR

LT-21121 PLC

SDCS-FEX-2A-0016 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922