Description

Product Overview and Description

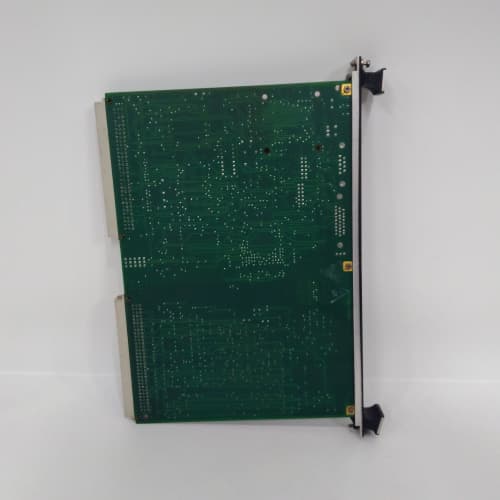

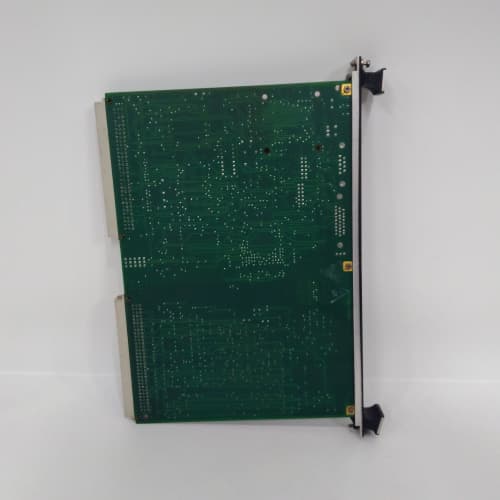

The GE IS200VTCCH1CBB is a critical turbine control interface board, specifically a Vibration/Temperature/Tachometer Control Card, designed for the GE Mark VI gas/steam turbine management system. This highly specialized module serves as a primary data acquisition and conditioning front-end for key turbine health and performance sensors. The GE IS200VTCCH1CBB accepts raw signals from vibration transducers (proximity probes, accelerometers), thermocouples or RTDs for temperature, and magnetic pickups for speed (tachometer), and converts them into clean, scaled digital data for the turbine’s central controller. Its role is fundamental to condition monitoring, protection, and performance calculation.

Product Parameters

- Board Type: Vibration, Temperature, and Tachometer (VTC) Signal Conditioning Card.

- Compatibility: GE Mark VI Turbine Control System (part of the Speedtronic family).

- Input Channels: Typically provides multiple dedicated input channels for:

- Vibration: Accepts signals from eddy-current proximity probes (e.g., 8 mm, 11 mm) for shaft relative vibration and axial position, and/or from seismic transducers for casing vibration.

- Temperature: Accepts inputs from thermocouples (Types J, K, T, E, etc.) or RTDs (Pt100, typically for bearing metal temperatures) with built-in cold junction compensation or excitation.

- Tachometer (Speed): Accepts signals from magnetic speed pickups (MPUs) or photocells to measure shaft rotational speed (RPM) for overspeed protection and phase reference.

- Signal Processing: Includes amplification, filtering, integration (for velocity), and analog-to-digital conversion.

- Communication: Interfaces with the Mark VI controller via a high-speed serial backplane (VME bus) or dedicated network.

- Diagnostics: Continuous self-check and sensor diagnostics (e.g., probe gap voltage, open/short detection).

- Configuration: Set up and calibrated via the Mark VI toolset (ToolboxST).

- Environmental Rating: Designed for the control cabinet environment of turbine installations.

Advantages and Key Features

- Critical Protection Function: The primary role of the GE IS200VTCCH1CBB is to provide reliable, high-integrity data for turbine protection. It enables immediate detection of excessive vibration or temperature, triggering automatic trips to prevent catastrophic mechanical damage.

- High Accuracy & Stability: Engineered for precision measurement, this card provides stable, low-drift signal conditioning essential for accurate trending and diagnosis of turbine mechanical condition over time.

- Multi-Signal Integration: By consolidating vibration, temperature, and speed conditioning on a single board, it simplifies system architecture, reduces cabling, and ensures synchronized data acquisition for comprehensive analysis.

- Advanced Diagnostics: The board and its associated software provide detailed diagnostics for the health of the connected sensors themselves, enabling predictive maintenance and preventing false trips due to faulty probes or wiring.

- Proven System Integration: As a native component of the Mark VI system, the GE IS200VTCCH1CBB is guaranteed to communicate seamlessly with the turbine controller (TMR or Simplex), allowing for centralized configuration, alarming, and data historization.

Application Cases in Various Fields

- Combined Cycle Power Plant: Monitoring axial and radial vibration on both the gas turbine and steam turbine shafts, bearing temperatures, and providing the critical 1st and 2nd overspeed protection signals via MPU inputs to the GE IS200VTCCH1CBB.

- Aeroderivative Gas Turbines: Providing essential condition monitoring for high-speed turbines used in power generation or mechanical drive, where vibration analysis is crucial for detecting imbalance or blade issues.

- Industrial Steam Turbines: Monitoring turbine casing expansion (Keyphasor), bearing temperatures, and shaft speed in a paper mill or refinery drive application.

- Pipeline Compression Stations: Protecting a turbine-driven compressor by monitoring vibration signatures that could indicate surge, bearing wear, or other mechanical faults, with data processed by the GE IS200VTCCH1CBB.

Comparison with Competing Products

The GE IS200VTCCH1CBB is a proprietary component within the GE Speedtronic ecosystem. Direct competitors would be similar vibration/temperature monitoring cards from other major turbine OEMs like Siemens (T3000 system modules) or Woodward (NetCon). Compared to standalone vibration monitoring systems from companies like Bently Nevada (now Baker Hughes) or Vibro-Meter, the GE IS200VTCCH1CBB is fully integrated into the primary turbine control and protection logic. Its advantage is this tight integration, allowing for fast protective actions. Standalone systems often offer more advanced analysis features but may have slower integration with the trip circuit. For a Mark VI turbine, this card is the specified, system-integrated solution for primary protection.

Selection Suggestions and Precautions

- Selection Advice:

- Exact Replacement: This board is almost exclusively selected as a direct, like-for-like replacement for a failed unit in an existing Mark VI rack. Verify the exact part number and revision from the failed board.

- Sensor Compatibility: Confirm the board’s firmware and hardware are configured for the specific sensor types (probe model, T/C type) installed on your turbine. Mismatches will yield incorrect readings.

- System Configuration: The replacement board will likely need its configuration (scaling, alarm setpoints) downloaded from the turbine’s ToolboxST project or manually reconfigured.

- Important Precautions:

- Critical Safety System: This board is part of the turbine’s safety instrumented system (SIS). Any work must be performed under a strict safety permit and by personnel trained on the Mark VI system.

- Electrostatic Discharge (ESD): Handle as a highly ESD-sensitive component. Use a grounded wrist strap and anti-static packaging.

- Power Down: Ensure the entire Mark VI rack is powered down and rack power supplies are discharged before removing or installing the GE IS200VTCCH1CBB.

- Configuration Backup: Before removing the old board, ensure a complete backup of the Mark VI controller configuration and this card’s parameters is secured.

- Calibration & Verification: After installation, the inputs must be verified and the system functionally tested according to the turbine’s commissioning procedures. This often involves simulating input signals to confirm trip setpoints.

- Source Authenticity: Due to its critical function, source the GE IS200VTCCH1CBB only from GE or certified, reputable refurbishers who can provide testing documentation. Counterfeit or untested boards pose a severe risk to turbine safety.

25-80-60090 PLC

SC510 PLC

5SHY3545L0014 PLC

DFP100 PLC

IS200STCIH2A PLC DCS

IC693CMM301 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922