Description

Product Description

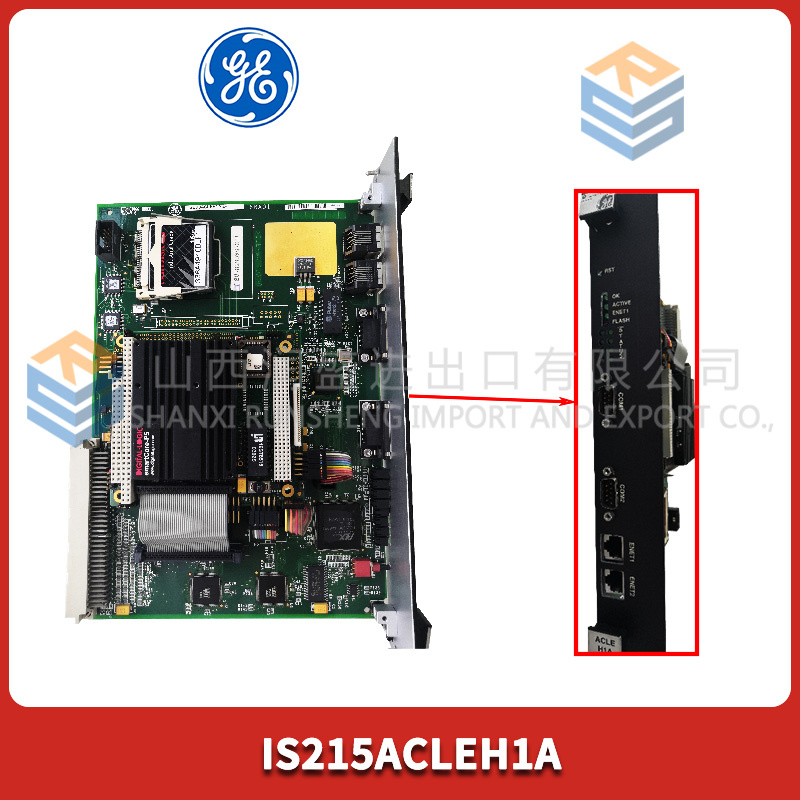

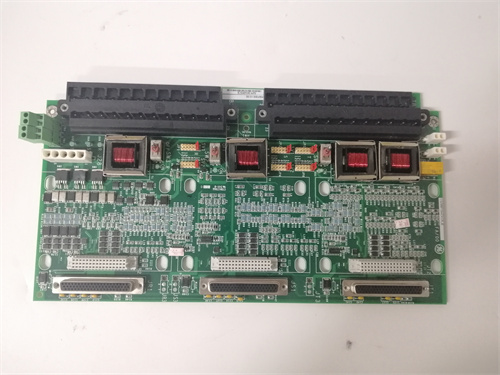

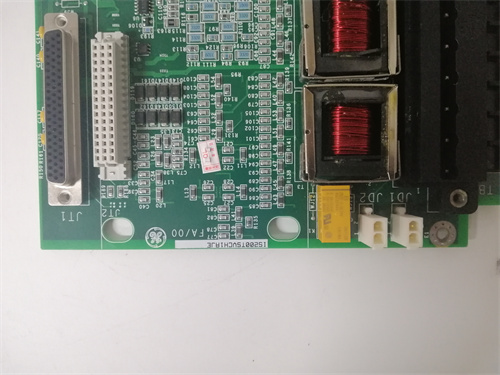

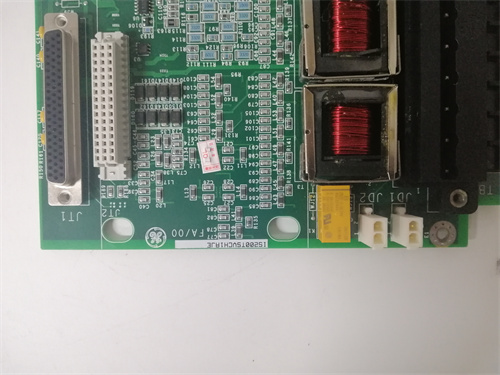

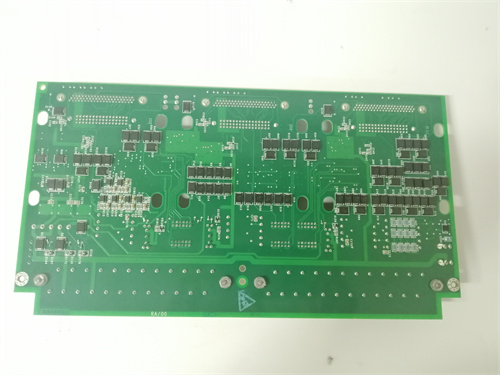

The GE IS200TSVCH1A is a critical component within a GE (General Electric) Mark VI or Mark VIe gas/steam turbine control system. This module is a Terminal Servo Control Board, designed to interface between the turbine’s digital control system and the analog servo valves that precisely position fuel controls, inlet guide vanes (IGVs), and other critical hydraulic or electro-hydraulic actuators. The GE IS200TSVCH1A receives low-voltage command signals from the main turbine controller and converts them into high-current, pulse-width modulated (PWM) or ±20 mA drive signals capable of operating high-performance servo valves. Its primary function is to provide the precise power amplification and signal conditioning necessary for fast, accurate positioning of final control elements. The reliability and precision of the GE IS200TSVCH1A are directly linked to the turbine’s ability to maintain efficient combustion, stable speed, and load control. Integrating the correct servo interface board, such as the GE IS200TSVCH1A (https://www.example-link-ge-product.com), is essential for the stable and responsive operation of the turbine’s fuel and compressor control systems.

Product Parameters / Technical Specifications

- Manufacturer: GE (General Electric)

- Product Family: Mark VI / Mark VIe Turbine Control System

- Module Type: Terminal Servo Control Board / Servo Valve Driver Board

- Series: IS200 Series (Mark VIe I/O and Termination Boards)

- Part Number: IS200TSVCH1A

- Primary Function: Drives and controls electro-hydraulic servo valves or proportional valves.

- Input Signals: Receives analog command signals (e.g., +/-10V DC) or digital signals from the turbine controller (TPC).

- Output Signals: Provides high-current drive output suitable for servo valve coils (e.g., +/-20 mA, PWM signals).

- Channels: Typically contains multiple independent servo control channels (e.g., 2 or 4 channels per board).

- Feedback Monitoring: Often includes circuits to monitor the valve’s actual position via a Linear Variable Differential Transformer (LVDT) or other position feedback device, closing a local loop for precise positioning.

- Diagnostics & Protection: Includes diagnostics for open coil, short circuit, and loss of feedback. May feature thermal overload protection.

- Power Supply: Requires both low-voltage logic power (from the backplane) and a higher-current external power supply for the servo valve outputs.

- Mounting: Designed to mount on a DIN rail or directly into a terminal board assembly within the turbine control cabinet.

Advantages and Key Features

- Precise Actuator Control: The GE IS200TSVCH1A is engineered for the high linearity and fast response required to accurately position turbine control valves, which is critical for efficiency and emissions compliance.

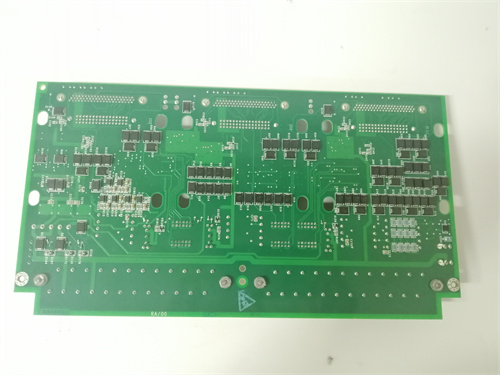

- Robust Industrial Design: Built to operate reliably in the high-vibration, high-temperature, and electrically noisy environment of a turbine enclosure.

- Integrated Diagnostics: Provides fault detection for the servo valve and its own circuitry, enabling predictive maintenance and preventing catastrophic control failures.

- System Integration: As a genuine GE component, it is designed to interface seamlessly with the Mark VIe controller’s architecture, communication, and diagnostic software (ToolboxST).

- Critical for Performance: Directly influences the turbine’s dynamic response to load changes and its ability to maintain stable operation during transients.

Application Cases in Various Fields

- Heavy-Duty Gas Turbines (Frame 7/9): Driving the servo valves that control fuel gas control valves and compressor inlet guide vanes (IGVs) for combustion and surge control.

- Aeroderivative Gas Turbines (LM Series): Providing the interface for fuel metering valve and variable stator vane control on LM2500 or LM6000 units.

- Steam Turbine Control: Positioning the governor valves and intercept valves that regulate steam flow.

- Compressor Control (Mechanical Drive): Managing the servo valves for anti-surge and performance control valves on pipeline compressors driven by a turbine.

- Turbine Retrofit Projects: Upgrading the servo interface portion of older hydraulic governor systems with a modern digital interface.

Comparison with Competing Products

The GE IS200TSVCH1A is a proprietary servo interface board for the GE turbine control ecosystem. Its direct competitors are similar servo driver modules from other turbine control OEMs like Siemens (for SGT turbines) and Woodward (NetCon). Its primary advantage is its certified compatibility and designed integration with the rest of the Mark VIe hardware and software, ensuring optimized performance and support. Compared to using generic industrial servo amplifiers, this board is purpose-built for the specific voltage levels, signal types, and mechanical interfaces (e.g., LVDT feedback) used in GE turbine servo systems.

Selection Suggestions and Precautions

- Selection Advice: The GE IS200TSVCH1A is selected only as a direct replacement for a failed board in an existing Mark VI/Mark VIe turbine control system. Selection is dictated 100% by the system’s bill of materials (BOM) and the exact part number on the failed unit. It is not a configurable or universal component.

- Precautions:

- Exact Part Number Match: The suffix “H1A” is critical. Different suffixes indicate different channel counts, output current ratings, or feedback types that will be incompatible.

- High-Current Power Supply: Verify the specifications for the external servo power supply. Incorrect voltage or insufficient current can damage the board or cause poor valve performance.

- Servo Valve Compatibility: Ensure the replacement board is compatible with the specific model of servo valve (coil impedance, required drive signal) installed in the turbine.

- Calibration and Setup: After replacement, the servo loop (command, driver, valve, LVDT feedback) will likely require calibration and tuning using the ToolboxST software. This is not a plug-and-play operation.

- Authorized Source Only: Due to its critical function in turbine control and safety, this board must be sourced from GE or an authorized GE turbine parts distributor to ensure authenticity and technical support.

- dav

ABB IMCIS22 PLC

ABB PM153 PLC

ABB PM152 PLC

ABB PM151 PLC

BB150 ABB PLC

ABB PM154

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922