Description

Product Overview and Description

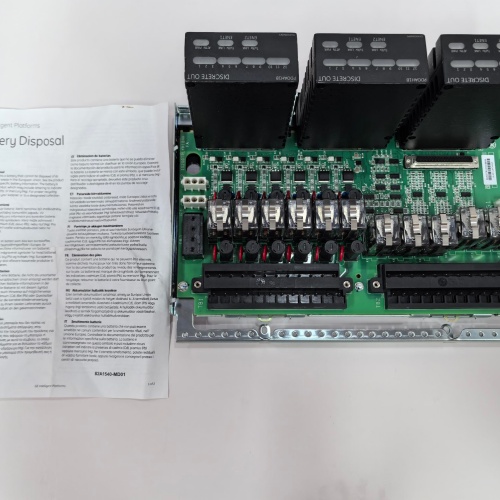

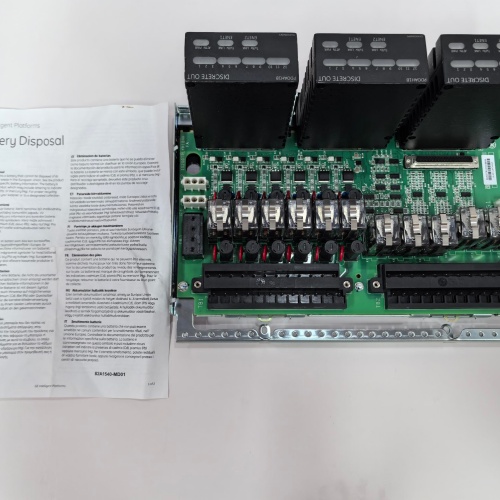

The GE IS200TDBSH2ACC is a critical Bridge Driver Output Module (also known as a Base Driver or BDA) for the Mark VIe gas/steam turbine control system from GE (now part of GE Vernova). This module is a sophisticated spare part within the Speedtronic family, designed to directly interface with and drive the power stages that control the fuel valves, inlet guide vanes (IGVs), or other critical actuators on a turbine. The GE IS200TDBSH2ACC acts as the vital link between the low-voltage control signals generated by the turbine’s TMR (Triple Modular Redundant) controllers and the high-power solenoids or servo valves in the hydraulic actuation system. Its robust design ensures precise and reliable control over the turbine’s speed, load, and temperature under extreme operating conditions. The performance and health of the GE IS200TDBSH2ACC are directly tied to the safe, efficient, and responsive operation of the entire turbine, making it one of the most critical I/O modules in the system.

Key Parameters and Specifications

- Manufacturer & System: GE, for the Mark VIe Speedtronic Turbine Control System.

- Module Type: Bridge Driver Output Module / Base Driver (BDA).

- Primary Function: Converts low-level logic command signals (from VCMI cards) into high-current drive signals for proportional or on/off valves.

- Output Configuration: Typically provides a dual H-bridge or similar output stage capable of sourcing and sinking current to drive a proportional solenoid coil.

- Output Current: Capable of delivering several Amperes (e.g., 2-4A continuous, higher peak) to an inductive load.

- Diagnostics: Extensive onboard diagnostics for fault detection, including open coil, short circuit, over-temperature, and over-current protection.

- Communication: Interfaces with the controller via the backplane (VME) and often includes a dedicated serial link (e.g., RS-485) for detailed status and configuration.

- Status Indicators: Multiple LEDs for power, channel status, communication, and fault conditions.

- Power Supply: Requires both control power (e.g., +5VDC, +15VDC) from the rack and often a separate, higher-power isolated supply for the output stage.

Advantages and Distinctive Features

The GE IS200TDBSH2ACC is engineered for maximum reliability and safety in mission-critical turbine control. Its primary advantage is providing a robust, intelligent, and isolated power interface that can directly drive final control elements with high precision and rapid response. A key feature is its comprehensive suite of diagnostics, which provides real-time feedback to the controller about the health of both the driver module itself and the field device (valve coil), enabling predictive maintenance and immediate fault response. The module’s design includes sophisticated protection circuits that prevent damage from field-side faults, such as shorts or opens, thereby enhancing overall system availability. The GE IS200TDBSH2ACC is specifically calibrated and tested to work seamlessly within the deterministic architecture of the Mark VIe, ensuring bumpless transfer and reliable operation during controller redundancies. Its rugged construction is validated for the high-vibration and wide-temperature environments typical of turbine platforms.

Application Cases in Key Fields

- Gas Turbine Power Generation: Directly driving the hydraulic actuators for fuel gas control valves (GCVs) to precisely regulate fuel flow, which directly controls turbine speed, load, and exhaust temperature (T-fire).

- Steam Turbine Control: Operating the servo valves for the main steam stop valves or control valves in a combined-cycle or cogeneration plant, managing steam flow and megawatt output.

- Aeroderivative Turbine Control (Mechanical Drive): Controlling the inlet guide vanes (IGVs) on a turbine used to drive a compressor in a pipeline or process plant, modulating airflow for efficiency and surge protection.

- Turbine Overspeed Protection: Acting as the final output stage for the emergency trip solenoid that dumps hydraulic pressure to close all fuel valves in an overspeed event.

Comparison with Competing Products

The GE IS200TDBSH2ACC is a proprietary, system-integral component. Competing output modules from other turbine control OEMs (e.g., Woodward NetCon or Siemens T3000) perform similar functions but are part of completely different hardware and software ecosystems and are not interchangeable. Standard industrial PLC analog output cards or generic solenoid drivers lack the high current capacity, the specific diagnostic feedback, the rigorous safety certifications, and the deep integration with turbine sequencing and protection logic that are inherent to the GE IS200TDBSH2ACC. Within the Mark VIe system, it is distinct from standard discrete or analog I/O packs, representing a specialized, high-integrity output stage for the most critical control loops.

Selection Suggestions and Precautions

Selection Suggestions:

- Select the GE IS200TDBSH2ACC exclusively as a replacement for a failed or suspect module within an existing GE Mark VIe turbine control system, as identified by the system’s part list or maintenance diagnostics.

- It should be procured as a critical spare part for any facility operating GE turbines with Mark VIe controls to minimize downtime in the event of a failure.

- Always verify the exact revision suffix and firmware compatibility with the existing controller rack.

Important Precautions:

- System-Specific Configuration: Each GE IS200TDBSH2ACC is configured with specific parameters (gain, limits, diagnostics thresholds) for its application (e.g., GCV vs IGV driver). The replacement module’s configuration must be restored from a known backup or meticulously set per the original unit’s settings.

- High-Energy Hazards: Maintenance must be performed only when the turbine is offline, the actuator hydraulic system is isolated and depressurized, and all control power is locked out/tagged out (LOTO). The output terminals can be connected to high-current circuits.

- Static Sensitive: Handle the module as an ESD-sensitive device using proper grounding straps and mats.

- Calibration: After installation, functional testing and potentially loop calibration may be required to ensure the actuator response matches the control signal precisely. This often involves specialized turbine service tools (ToolboxST).

- Root Cause Analysis: A failure of a GE IS200TDBSH2ACC is frequently caused by an external fault, such as a shorted solenoid coil or water intrusion. Always investigate and rectify the root cause in the field wiring or the connected device before installing a new module to prevent immediate re-failure.

ABB SAFT120PAC I/O

SAFT171PAC ABB I/O

ABB SAFT187CON PLC

SAFT110POW ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922