Description

Product Description

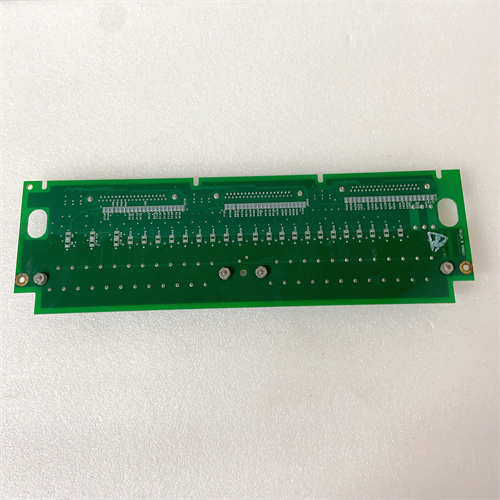

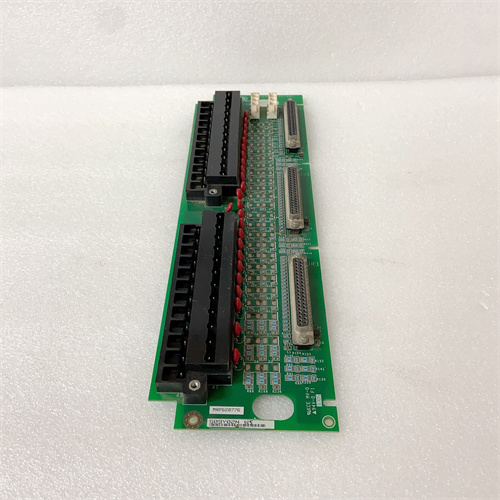

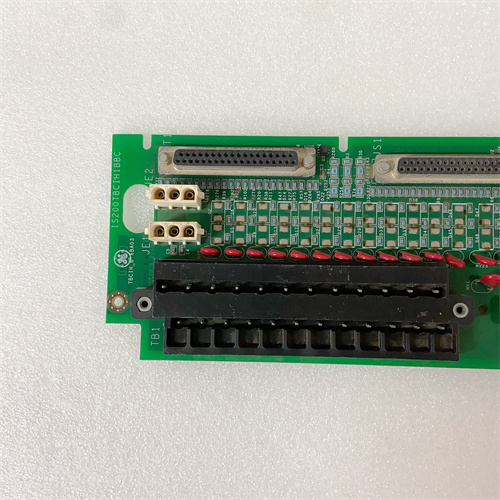

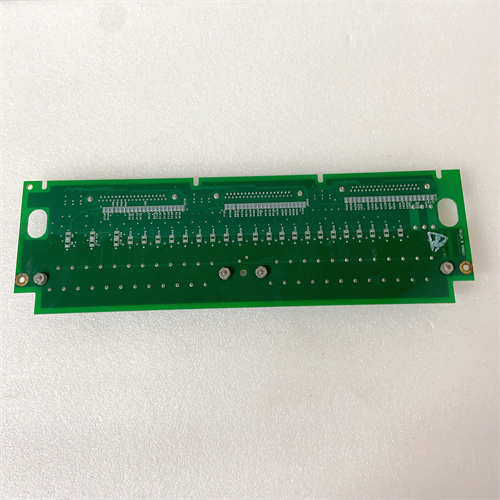

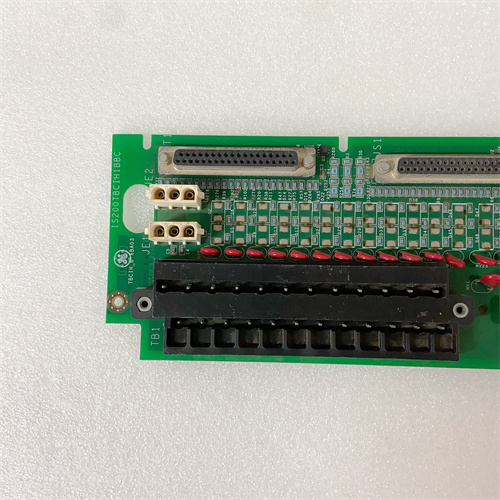

The GE IS200TBCIH2CAA is a critical interface and control module within the GE Mark VI or Mark VIe gas/steam turbine control system. This module, a Terminal Board Control I/O card, is designed to provide a robust interface between the turbine’s main control processor and critical field devices, particularly those involved in temperature sensing and control. Based on the “TBCI” designation, this board is highly likely a Terminal Board for Thermocouple/RTD Inputs. The GE IS200TBCIH2CAA provides signal conditioning, isolation, and analog-to-digital conversion for multiple temperature sensors, such as thermocouples or Resistance Temperature Detectors (RTDs), which monitor critical points like bearing temperatures, exhaust gas temperatures, and metal temperatures. Its design ensures accurate, reliable temperature measurement in the electrically noisy and high-vibration environment of a turbine enclosure. The reliability of the GE IS200TBCIH2CAA is paramount for turbine protection, efficiency optimization, and emissions compliance. Integrating the correct temperature input board, such as the GE IS200TBCIH2CAA (https://www.example-link-ge-product.com), is essential for safe and efficient turbine operation. The specific suffix “H2CAA” defines the precise hardware configuration, calibration, and I/O channel types.

Product Parameters / Technical Specifications

- Manufacturer: GE (General Electric)

- Product Family: Mark VI / Mark VIe Turbine Control System

- Module Type: Terminal Board for Temperature Input (Thermocouple/RTD)

- Series: IS200 Series (Mark VIe I/O and Termination Boards)

- Part Number: IS200TBCIH2CAA

- Primary Function: Conditions and digitizes signals from temperature sensors.

- Input Types: Configurable for various sensor types:

- Thermocouples: Types J, K, T, E, etc., for high-temperature measurements (e.g., exhaust gas).

- RTDs: Typically Pt100 or Pt1000 for precise temperature measurement (e.g., bearing, winding temperatures).

- Number of Channels: Typically provides multiple isolated input channels (e.g., 8, 16, or 32 channels).

- Cold Junction Compensation (CJC): Integrated for accurate thermocouple measurement.

- Isolation: High channel-to-channel and channel-to-system isolation to prevent ground loops and ensure signal integrity.

- Accuracy & Resolution: High accuracy and resolution suitable for precise temperature monitoring and control.

- Diagnostics: Includes diagnostics for open sensor, short circuit, and out-of-range conditions.

- Communication: Interfaces with the turbine controller’s I/O network.

- Power Supply: Requires power from the system backplane and possibly an external supply for sensor excitation (for RTDs).

- Mounting: Designed for installation in a Mark VIe terminal board assembly.

Advantages and Key Features

- High-Precision Temperature Measurement: The GE IS200TBCIH2CAA is engineered for the accurate and stable measurement required for turbine protection and performance calculation.

- Robust Signal Conditioning: Provides excellent noise immunity and isolation, ensuring reliable data in the challenging electrical environment of a power generation facility.

- Integrated Diagnostics: Open thermocouple and RTD detection allows for predictive maintenance and prevents undetected sensor failures from compromising safety.

- Scalable Channel Density: Allows monitoring of numerous temperature points from a single board, optimizing cabinet space.

- Seamless System Integration: As a genuine GE component, it is fully compatible with the Mark VIe controller’s hardware and ToolboxST software, ensuring correct configuration and calibration.

Application Cases in Various Fields

- Heavy-Duty Gas Turbines: Monitoring exhaust gas temperature (EGT) from multiple thermocouples for combustion tuning and turbine protection in Frame 7FA/9FA units.

- Aeroderivative Gas Turbines: Measuring bearing temperatures and fuel gas temperatures on LM2500 or LM6000 turbines.

- Steam Turbines: Monitoring bearing metal temperatures, steam chest temperatures, and gland seal steam temperatures.

- Compressor Stations: Protecting turbine-driven compressors by monitoring bearing and case temperatures.

- Combined Heat and Power (CHP) Plants: Providing temperature inputs for both the turbine and associated heat recovery systems.

Comparison with Competing Products

The GE IS200TBCIH2CAA is a proprietary temperature input module for the GE turbine control ecosystem. Its direct competitors are similar high-density, ruggedized temperature input cards from other turbine control OEMs like Siemens and Woodward. Its primary advantage is its certified performance and seamless integration within the Mark VIe system, which is the dominant platform for GE turbines. Compared to using generic temperature transmitters or data acquisition cards, this board is purpose-built for the safety-critical, high-reliability, and specific signal conditioning requirements of turbine temperature monitoring, with direct support from GE’s turbine engineering services.

Selection Suggestions and Precautions

- Selection Advice: The GE IS200TBCIH2CAA is selected exclusively for repairing or sparing a specific Mark VI/Mark VIe turbine control system. Selection is driven 100% by the existing system’s bill of materials (BOM) and the module’s exact position in the temperature monitoring scheme. The full part number IS200TBCIH2CAA must be matched precisely.

- Precautions:

- Exact Part Number Match: The suffix “H2CAA” is critical. Different suffixes indicate different sensor type compatibility (e.g., thermocouple vs. RTD), channel counts, or calibration that will be incompatible.

- Sensor Compatibility: Verify the board is configured for the specific type of sensor (TC type or RTD) wired to each channel. Mismatching will give wildly incorrect readings.

- Wiring and Shielding: Use the correct extension wire for thermocouples or 3-wire/4-wire configuration for RTDs. Proper shielding and grounding are essential to avoid noise.

- Calibration: While the board is pre-calibrated, the overall loop accuracy depends on the sensor. Critical temperature points may require loop calibration after board replacement.

- Authorized Source Only: Due to its critical role in turbine protection and safety, this module must be sourced from GE or an authorized GE turbine parts distributor to ensure authenticity, calibration, and support.

1SBP260101R1001 PLC

ABB Z0EB01B-E PLC

SAFT160F380

ABB SAFT110 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922