Description

Product Description

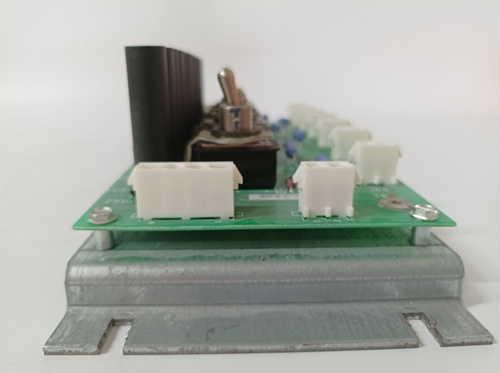

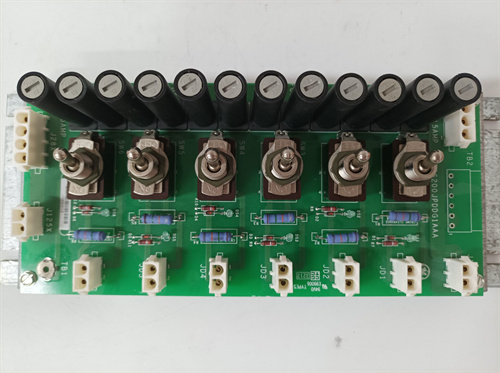

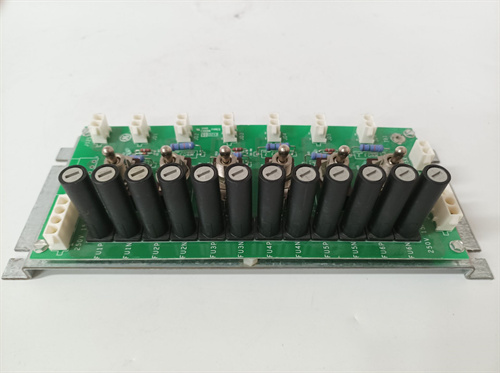

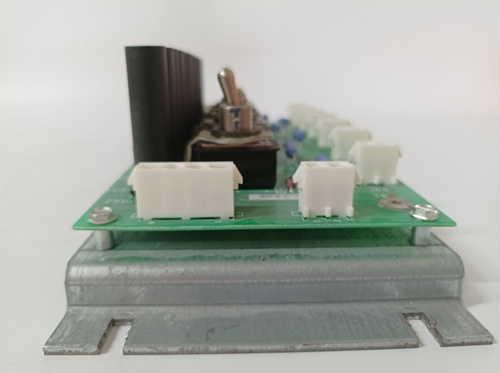

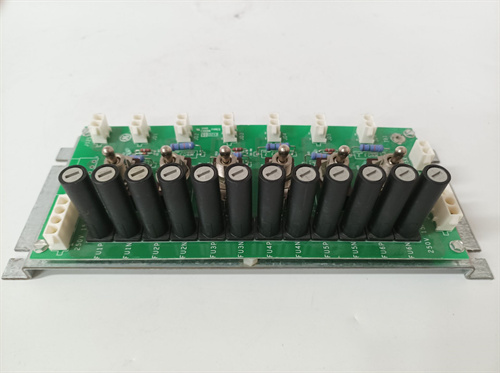

The GE IS200JPDDG1AAA is a junction board module engineered specifically for GE’s Mark VI and Mark VIe Speedtronic turbine control systems, serving as the critical interconnection interface between turbine-mounted sensors, I/O modules, and termination panels. This dedicated printed circuit board provides organized, reliable termination for speed pickups, vibration probes, thermocouples, and pressure transmitters distributed throughout gas and steam turbine generator installations. The GE IS200JPDDG1AAA functions as the central wiring hub within GE’s simplex and triple modular redundant turbine control architectures, consolidating field wiring from dozens of turbine sensors into standardized ribbon cable connections to I/O packs. Designed for continuous operation in extreme turbine hall environments, this module withstands significant vibration, elevated temperatures, and electromagnetic interference characteristic of high-power generation equipment. The GE IS200JPDDG1AAA mounts within GE’s IS200 series drive control panels and interfaces directly with Mark VIe I/O packs via GE’s proprietary backplane and ribbon cable interconnect system.

Product Parameters

- Model: GE IS200JPDDG1AAA

- Product Type: Junction Board, Turbine Control System

- System Compatibility: GE Mark VI, Mark VIe Speedtronic

- Function: Sensor signal aggregation and distribution

- Input Connections: Multiple terminal blocks for field device wiring

- Output Connections: Ribbon cable headers to I/O packs (IDC type)

- Supported Sensors: Magnetic pickups, proximity probes, accelerometers, RTDs, thermocouples, 4–20 mA transmitters

- Signal Conditioning: Passive (direct pass-through) with overvoltage protection

- Protection: Transient suppression, reverse polarity protection on power inputs

- Indicators: Power present LED, optional channel status (variant dependent)

- Mounting: Panel mount, IS200 drive rack

- Power Supply: 24 V DC or ±15 V DC from backplane connection

- Connectors: 50-pin ribbon cable headers, 2-piece terminal blocks, D-subminiature

- Operating Temperature: -30°C to +65°C

- Vibration Rating: 5 g @ 10–500 Hz

- Certifications: CE, UL, CSA, ATEX Zone 2, IEEE C37.90, marine type approval

Advantages and Features

The GE IS200JPDDG1AAA delivers critical infrastructure for turbine control reliability through its systematic organization of field wiring, transforming complex, distributed sensor arrays into maintainable, documented interconnection points. Unlike generic terminal blocks requiring point-to-point tracing, the GE IS200JPDDG1AAA provides clearly labeled, grouped terminations corresponding to specific turbine functions—speed, vibration, temperature, pressure, and flame detection—dramatically reducing troubleshooting time. The board incorporates comprehensive transient voltage suppression on all field inputs, protecting sensitive Mark VIe I/O electronics from lightning-induced surges and switching transients coupled through turbine instrumentation wiring. Built-in test points provide safe access for maintenance personnel to verify sensor signals without disrupting operating turbine control circuits. The GE IS200JPDDG1AAA‘s modular architecture enables partial board replacement during outages, as individual sensor groups can be isolated while maintaining turbine operation on redundant measurement channels. Its ribbon cable interface eliminates hundreds of individual wires between junction boards and I/O packs, reducing assembly errors and improving panel airflow for thermal management. The board’s rugged FR-4 construction with 2-ounce copper provides exceptional current-carrying capacity and resistance to thermal cycling fatigue common in peaking turbine applications.

Application Cases in Application Fields

- Gas Turbine Generator Sets: Deployed on GE 7FA heavy-duty gas turbines, the GE IS200JPDDG1AAA consolidates 24 vibration probe signals from turbine bearings and casing accelerometers, providing organized termination to Mark VIe protection I/O modules for API 670 compliant machinery monitoring.

- Steam Turbine Retrofit Projects: Installed on non-GE steam turbines undergoing Mark VIe control system upgrades, multiple GE IS200JPDDG1AAA junction boards adapt existing field wiring from diverse sensor types to GE’s standardized I/O interface, eliminating complete turbine re-instrumentation.

- Combined Cycle Balance of Plant: Utilized on heat recovery steam generator feedwater pump turbines, the GE IS200JPDDG1AAA terminates speed pickup and vibration probe wiring in remote I/O enclosures, extending GE Mark VIe control to auxiliary turbine packages.

- Offshore Platform Power Generation: Applied on GE LM2500 aeroderivative gas turbines in North Sea production facilities, the GE IS200JPDDG1AAA‘s conformal-coated variant provides corrosion resistance in salt-laden atmosphere, ensuring reliable operation between platform maintenance campaigns.

- Pipeline Compressor Stations: Implemented on GE PGT25 gas turbine-driven centrifugal compressors, the GE IS200JPDDG1AAA consolidates surge control pressure transmitter signals, compressor speed pickups, and turbine exhaust thermocouples into single junction board assemblies.

Comparison with Competing Products

| Feature | GE IS200JPDDG1AAA | Woodward MicroNet Junction Board | Siemens S7-400 FM Junction Module | ABB Procontrol P14 Terminal Unit |

|---|---|---|---|---|

| Primary Application | GE Mark VI/VIIe turbine I/O consolidation | Woodward turbine control I/O | General purpose industrial I/O | ABB Procontrol turbine I/O |

| Sensor Types | MPU, proximity, vibration, RTD, TC, 4–20 mA | MPU, proximity, vibration, RTD, TC | DI, DO, AI (via signal conditioners) | MPU, proximity, vibration, RTD, TC |

| Integrated Protection | Transient suppression on all inputs | Transient suppression on critical inputs | None (requires external modules) | Transient suppression |

| Signal Conditioning | Passive (direct pass-through) | Active (amplification, filtering) | None | Passive |

| I/O Interface | Ribbon cable to I/O packs | Discrete wiring to controller | Profibus/Profinet | S100 I/O bus |

| System Integration | Mark VI/VIIe native | Woodward native | S7-400 universal | Procontrol native |

| Marine Approval | Yes | Yes | Optional | Yes |

| Typical Cost Position | Mid | Mid-High | Low-Mid | High |

The GE IS200JPDDG1AAA distinguishes itself through its seamless integration with GE Speedtronic architecture, providing form-fit-function compatibility that third-party junction solutions cannot achieve without significant engineering modification. While Woodward’s MicroNet junction boards offer active signal conditioning, this capability is unnecessary for GE systems where I/O packs perform all required sensor excitation and linearization. Siemens S7-400 FM junction modules, while lower cost, lack turbine-specific sensor support and transient protection essential for generator applications. The GE IS200JPDDG1AAA‘s passive design provides superior reliability compared to active junction electronics, as it contains no active components subject to failure. For GE turbine operators, the GE IS200JPDDG1AAA represents the only fully supported, configuration-managed junction solution for Mark VI and VIe control systems.

Selection Suggestions and Precautions

- Model Variant Verification: The GE IS200JPDDG1AAA is one of numerous JPDD variants; verify that suffix “AAA” matches your specific turbine application requirements, as different suffixes indicate variations in connector types, transient suppression levels, and sensor compatibility.

- I/O Pack Compatibility: Confirm that your Mark VIe I/O pack type is compatible with the GE IS200JPDDG1AAA interface; speed and vibration I/O packs require specific ribbon cable pinouts that vary between analog input, digital input, and dedicated protection I/O modules.

- Field Wiring Termination: The GE IS200JPDDG1AAA accepts 14–22 AWG wire on terminal blocks; use ferrules on stranded conductors and tighten to 0.5–0.6 Nm; insufficient torque is a leading cause of intermittent sensor signals in high-vibration turbine applications.

- Ribbon Cable Installation: When connecting GE IS200JPDDG1AAA to I/O packs, ensure ribbon cable polarization aligns with keyed headers; forced insertion with incorrect orientation damages both junction board and I/O pack connectors, requiring board replacement.

- Spare Parts Strategy: Given the GE IS200JPDDG1AAA‘s critical role in turbine I/O infrastructure and typical lead times of 8–12 weeks, maintain configured spare junction boards for each turbine installation; passive design means spares have virtually unlimited shelf life when stored in static-shielded packaging.

- Environmental Considerations: Although rated for turbine hall environments, protect the GE IS200JPDDG1AAA from direct steam leaks, water spray, and excessive dust accumulation; install in NEMA 12 enclosures for severe service applications.

- Documentation Requirements: Maintain accurate as-built documentation of GE IS200JPDDG1AAA field wiring assignments; without current termination drawings, troubleshooting turbine sensor faults becomes extremely time-consuming and error-prone.

- Retrofit Planning: When upgrading from Mark V to Mark VIe control, existing turbine field wiring can often be re-terminated on new GE IS200JPDDG1AAA junction boards; however, verify that sensor types are compatible with Mark VIe I/O pack excitation requirements before committing to re-termination.

- Grounding Practice: The GE IS200JPDDG1AAA requires single-point grounding of shield wires at the junction board entry; do not connect multiple shield ground points, which create ground loops and introduce 50/60 Hz interference into turbine protection circuits.

- Obsolescence Awareness: The GE IS200JPDDG1AAA remains supported for Mark VIe systems, but GE’s future control platform direction is Mark VIe Distributed I/O; facilities planning major capital projects should evaluate junction board requirements for next-generation architectures.

- Connector Maintenance: Ribbon cable IDC connectors on the GE IS200JPDDG1AAA are rated for limited insertion cycles; avoid unnecessary disconnection during troubleshooting and consider sacrificial patch cables for test access to preserve junction board connector life.

- Pre-Commissioning Verification: Before turbine start-up, perform complete loop checks on all GE IS200JPDDG1AAA terminated sensors; document baseline signal levels and compare with manufacturer specifications to identify marginal sensors before they cause operational trips.

TRICONEX 4107

TRIC0NEX 4118 PLC

TRICONEX 4119 PLC

TRICONEX 4119A

TRIC0NEX 4201

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922