Description

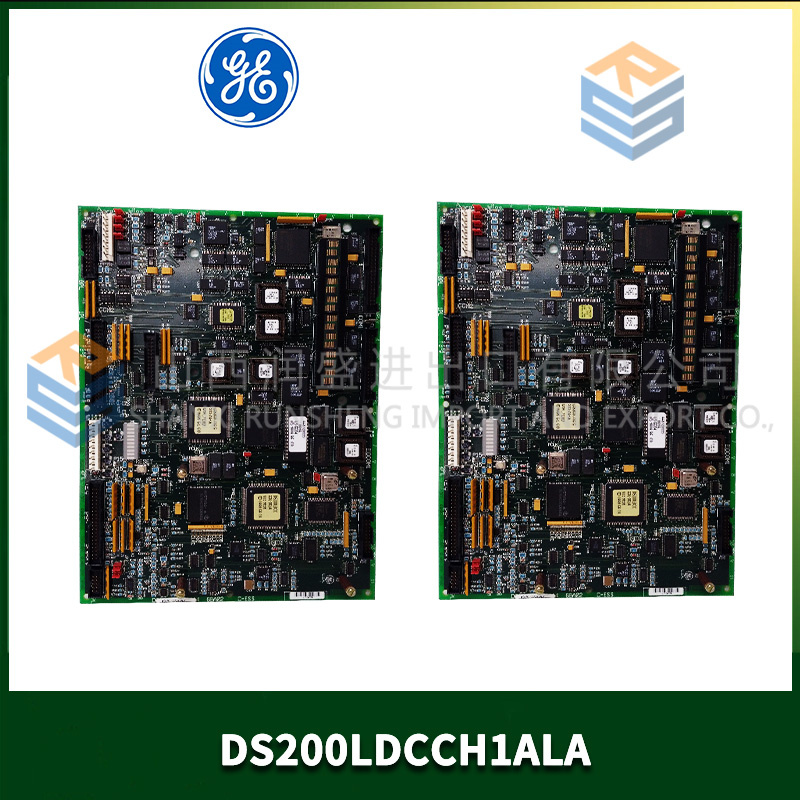

Product Description

The GE IS200BPPBH2B is a high-performance Base Power/Processor Board designed as a core component for the GE Mark VIe series, a leading distributed control and protection system for industrial turbines and critical machinery. This essential board, often the central processing module within a turbine control rack, integrates a powerful processor with fundamental system I/O and communication interfaces. The primary function of the IS200BPPBH2B is to execute the application control logic, manage local I/O modules, and handle critical communication with other system nodes and the operator interface. For engineers seeking reliable turbine control, the GE IS200BPPBH2B provides the computational heart of the system. It is engineered for deterministic performance in demanding environments, ensuring precise control over speed, temperature, and sequencing. Detailed specifications and support documents for this key module can be reviewed on the official product page for the GE IS200BPPBH2B. The robust design and proven architecture of this IS200BPPBH2B module make it a cornerstone for both new installations and legacy system maintenance.

Product Parameters/Key Specifications

- Manufacturer: GE Industrial Systems (General Electric)

- Series: Mark VIe Speedtronic Turbine Control System

- Function: Base Power/Processor Board (Combined Processor and Base Board)

- Processor: Features an embedded high-performance processor for executing control algorithms.

- Memory: Includes onboard RAM and flash memory for the operating system, application logic, and data storage.

- Communication Ports:

- Ethernet ports for peer-to-peer (CMM) network communication and/or plant network connectivity.

- Serial port for diagnostics and configuration.

- Backplane Interface: Connects directly to the VME-style backplane of a Mark VIe controller rack to communicate with and manage I/O packs (like AI, DI, AO, DO modules).

- Power Supply: Receives system power via the backplane and conditions it for onboard use.

- Status Indicators: Multiple LEDs for power, processor status, network activity, and fault indications.

- Firmware: Runs the GE Mark VIe operating system and is programmed using GE’s ToolboxST application.

Advantages and Key Features

- Integrated Design: Combines the processor and base board functions into a single, robust module, simplifying the controller architecture and reducing inter-board connections.

- Deterministic Performance: Engineered for real-time control, providing predictable scan times critical for high-speed turbine protection and sequencing.

- Robust Communication: Integrated dual Ethernet interfaces support high-speed, redundant network communication for distributed control architectures.

- Comprehensive Diagnostics: Extensive LED status indicators and software-readable diagnostics enable rapid health monitoring and troubleshooting, minimizing downtime.

- High Reliability: Built with industrial-grade components designed for 24/7 operation in environments with temperature fluctuations and electrical noise common in power generation.

- Seamless Ecosystem Integration: Fully compatible with the entire GE Mark VIe I/O portfolio and programmed with the standard ToolboxST software, ensuring engineering efficiency.

Application Cases in Industry

The IS200BPPBH2B is deployed as the primary controller in GE Mark VIe systems across heavy-duty industries:

- Gas & Steam Turbine Power Generation: Serves as the main processing unit in control cabinets for large Frame turbines in combined-cycle or simple-cycle power plants, executing critical speed, temperature, and load control logic.

- Oil & Gas Compression: Used to control and protect turbine-driven compressors on pipelines or offshore platforms, managing anti-surge algorithms and sequencing.

- Mechanical Drive Applications: Provides control for industrial turbines driving pumps, fans, or other large equipment in refining, chemical, and manufacturing plants.

- System Upgrades and Retrofits: A vital spare part for maintaining and modernizing existing Mark VIe installations, allowing for processor replacement or system expansion without a full platform changeout.

Comparison with Competing Products

- Vs. Earlier GE Mark VI Processors: The IS200BPPBH2B for the Mark VIe platform represents an architectural advancement over the separate VCM3/VCMI processor and base board used in the older Mark VI. It offers improved processing power, integrated networking, and a more streamlined hardware design.

- Vs. Other OEM Turbine Controllers (Woodward, Allen-Bradley): Unlike a general-purpose PLC (e.g., Allen-Bradley ControlLogix), the GE IS200BPPBH2B is purpose-built for turbine control with deterministic performance, native I/O for speed sensing, and specialized firmware blocks for turbine sequencing and protection. Competing turbine controllers from Woodward offer similar specialization but are tied to their own proprietary hardware and software ecosystems.

- Vs. Newer GE Mark VIeS: The IS200BPPBH2B is a core component of the standard Mark VIe. The newer Mark VIeS (Secure) system may utilize different or enhanced processor boards with added security features but maintains compatibility with much of the I/O and ToolboxST environment.

Selection Suggestions and Precautions

- Verify Exact System Configuration: Confirm your controller is a Mark VIe (not Mark VI or Mark V) and that the specific rack and I/O configuration is compatible with the IS200BPPBH2B. Check the hardware revision (H2B) against existing spares or documentation.

- Firmware and Application Backup: Crucial: Before replacing a processor board, always backup the application logic and note the firmware version from the original module using ToolboxST. The new IS200BPPBH2B may need its firmware updated and the application downloaded.

- Source Authentic Modules: Due to its critical role, procure this module from authorized GE channels or certified refurbishment centers to guarantee functionality and firmware legitimacy. Counterfeit boards can cause catastrophic system failures.

- ESD and Handling Procedures: This is a sensitive electronic component. Use proper anti-static (ESD) handling precautions during storage, transport, and installation.

- Replacement Procedure: Swapping a base processor board typically requires a full controller shutdown. Follow detailed GE procedures to power down the rack, replace the module, power up, and restore the application. Incorrect sequencing can damage the module or corrupt control logic.

- Consider the Control Core Replacement: In many cases, replacing the IS200BPPBH2B is effectively replacing the entire control core. Ensure you have the necessary software, cables, and expertise to properly commission the new module.

SJA50VW430-A

6AV6642-0DC01-1AX1 PLC

CACR-SR15BB1BM PLC

6SN1146-1BB02-0CA1 PC

5C5601.32 PLC

VT-VPCD-1-1X/V0/1-0-1 PLC

HMCP400X5W PLC

DS200CDBAG1BCB

6445-001-K-N

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922