Description

Initial Product Description & Link

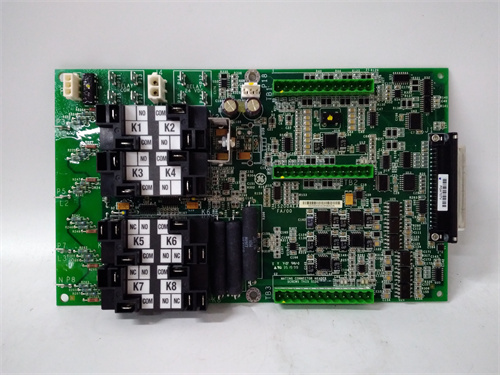

The core device is GE IS200AEADH1A, an industrial-grade analog input module developed by GE, specifically designed for high-precision acquisition of analog signals (such as temperature, pressure, and flow) from field sensors in power generation, oil & gas, and heavy manufacturing industries. It serves as a critical interface between field instruments and GE’s Mark VIe DCS (Distributed Control System), ensuring reliable data transmission for process control and monitoring. The product link will be provided later; below is a detailed overview based on its key functions and applications.

Core Product Description

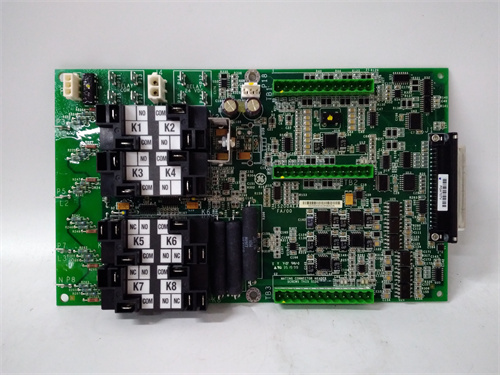

GE IS200AEADH1A belongs to GE’s Mark VIe series of I/O (Input/Output) modules, a product line widely adopted in turbomachinery control systems (e.g., steam turbines, gas turbines, and generators). Its primary role is to convert weak analog signals from field sensors (e.g., 4-20mA current signals from pressure transmitters, 0-10V voltage signals from temperature transducers) into digital data compatible with the Mark VIe DCS. This conversion process maintains ultra-high accuracy, making it suitable for critical parameters that directly impact equipment safety and operational efficiency.

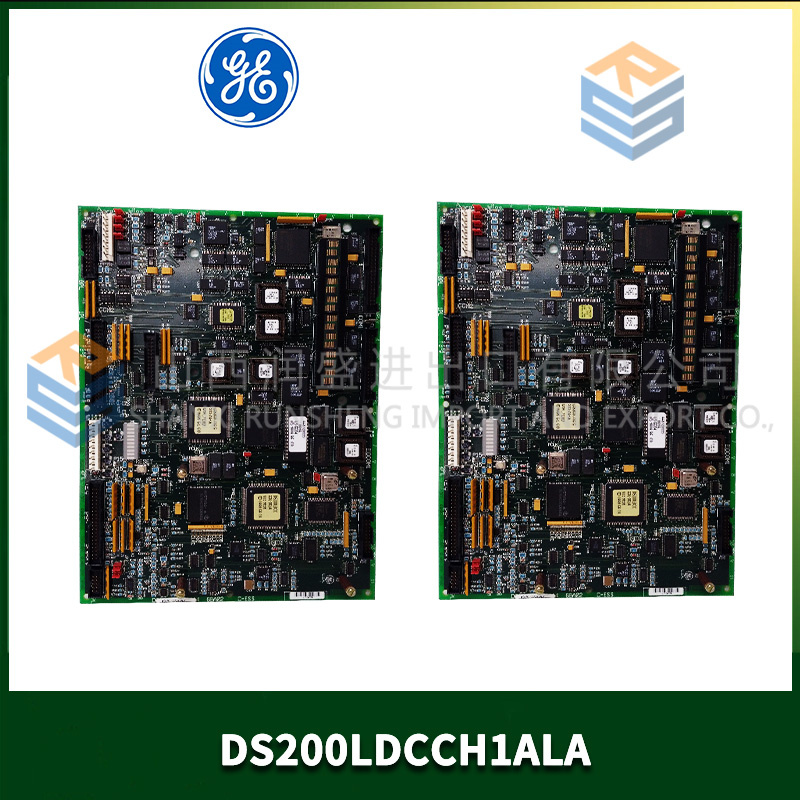

A standout feature of GE IS200AEADH1A is its “redundant design capability”—when paired with another identical module, it forms a 1+1 redundant configuration to prevent data loss due to single-module failures. For example, in a coal-fired power plant’s turbine control system, GE IS200AEADH1A collects analog signals from 8 key sensors (e.g., steam pressure, turbine bearing temperature, and lubricating oil pressure). If one module malfunctions, the redundant unit immediately takes over, ensuring the DCS continues receiving real-time data without interrupting turbine operation. Additionally, GE IS200AEADH1A integrates advanced noise filtering and isolation technologies, enabling stable operation in harsh industrial environments with strong electromagnetic interference (EMI) and temperature fluctuations.

Key Technical Specifications

| Parameter Category | Detailed Specifications |

|---|---|

| Module Type | Analog Input (AI) Module for GE Mark VIe DCS |

| Number of Input Channels | 8 differential analog input channels (supports simultaneous signal acquisition) |

| Supported Signal Types | 4-20mA DC (current signal), 0-10V DC (voltage signal), RTD (Pt100/Pt1000, for temperature) |

| Signal Resolution | 16 bits (ensures high-precision data conversion) |

| Measurement Accuracy | ±0.1% of full scale (at 25°C); ±0.2% of full scale (over operating temperature range) |

| Isolation | 2500V AC galvanic isolation (between channels, and between channels and power supply) |

| Power Supply | 24V DC (tolerance: ±10%); Power consumption: ≤12W |

| Operating Temperature | -40°C ~ +70°C (adapts to extreme cold and high-temperature environments) |

| Protection Rating | IP20 (panel-mounted, suitable for installation inside control cabinets) |

| Communication Interface | GE’s proprietary backplane bus (connects to Mark VIe controller, transmission rate: 1Gbps) |

| Compatibility | GE Mark VIe DCS, GE Turbine Control Systems (e.g., Speedtronic), third-party PLCs (via gateway) |

Core Advantages & Features

- High Precision and Reliability: With 16-bit resolution and ±0.1% full-scale accuracy, GE IS200AEADH1A ensures minimal signal distortion during analog-to-digital conversion. For instance, a 12mA current signal from a pressure transmitter is converted to digital data with an error of less than ±0.012mA—critical for applications like steam pressure control in turbines, where even small deviations can affect efficiency or safety.

- Redundancy Support for Fault Tolerance: The module is designed for 1+1 redundancy, a must-have for mission-critical systems (e.g., nuclear power plant turbomachinery). If a primary GE IS200AEADH1A module fails, the redundant unit switches over in <10ms, eliminating data loss and process downtime.

- Strong Environmental Adaptability: Equipped with 2500V AC galvanic isolation and EMI filtering, GE IS200AEADH1A resists interference from nearby high-power equipment (e.g., motors, transformers). Its wide operating temperature range (-40°C ~ +70°C) also makes it suitable for outdoor or high-heat applications, such as oil refinery process units.

- Seamless Integration with GE Ecosystem: As a native component of the GE Mark VIe DCS, GE IS200AEADH1A requires no additional drivers or adapters. It is automatically recognized by the DCS during startup, and its status (e.g., channel health, signal quality) can be monitored in real time via GE’s HMI software (e.g., CIMPLICITY), simplifying configuration and maintenance.

Typical Application Scenarios

- Power Generation – Turbine Control: In a combined-cycle power plant, GE IS200AEADH1A is installed in the turbine control cabinet. It collects analog signals from 8 sensors: 4 for steam pressure/temperature, 2 for bearing temperature (via Pt100 RTDs), and 2 for lubricating oil pressure. The data is transmitted to the Mark VIe DCS, which adjusts fuel supply and valve positions to optimize turbine efficiency and prevent overheating.

- Oil & Gas – Pipeline Pressure Monitoring: In a natural gas pipeline system, GE IS200AEADH1A acquires 4-20mA signals from pipeline pressure transmitters. Its noise filtering feature suppresses interference from pipeline pumps, ensuring accurate pressure readings. If pressure exceeds a safe threshold, the DCS triggers an alarm or shuts down valves via connected output modules.

- Heavy Manufacturing – Steel Mill Furnace Control: In a steel mill’s blast furnace system, the module collects temperature signals from RTD sensors (Pt100) inside the furnace. The high-precision data enables the DCS to regulate fuel and air flow, maintaining the furnace temperature at 1500°C ±5°C—critical for producing high-quality steel and avoiding furnace damage.

Comparison with Competitors (vs. a Generic Analog Input Module)

| Comparison Dimension | GE IS200AEADH1A | Generic Analog Input Module |

|---|---|---|

| Accuracy | ±0.1% of full scale | ±0.5% of full scale |

| Isolation Voltage | 2500V AC | 1500V AC |

| Redundancy Support | Yes (1+1 redundancy) | No (single-module operation, high downtime risk) |

| Operating Temperature Range | -40°C ~ +70°C | 0°C ~ +60°C |

| Compatibility with GE Systems | Native integration with Mark VIe DCS | Requires external gateway (higher cost/complexity) |

Selection Recommendations & Usage Precautions

Selection Recommendations

- Match with Application Requirements: Choose GE IS200AEADH1A if you need high-precision analog signal acquisition (e.g., turbine control, nuclear power) or operate in extreme environments (-40°C ~ +70°C). For less critical applications (e.g., general factory temperature monitoring), consider GE’s cost-effective IS200AETAH1A (4-channel) module.

- Redundancy Configuration: For mission-critical systems (e.g., power plant turbines), always configure two GE IS200AEADH1A modules in 1+1 redundancy. Ensure both modules use the same firmware version to avoid compatibility issues during switchover.

- Sensor Compatibility Check: Verify that field sensors (e.g., RTDs, transmitters) match the module’s signal requirements. For example, if using a Pt100 RTD, confirm the module’s RTD input range (0-200°C or 0-400°C) aligns with the sensor’s measurement range.

Usage Precautions

- Proper Wiring: Use shielded twisted-pair cables for signal wiring to reduce EMI. Ground the cable shield only at the module end (not at the sensor end) to prevent ground loops. For RTD signals, use 3-wire or 4-wire wiring to eliminate lead resistance errors.

- Regular Calibration: Calibrate GE IS200AEADH1A annually using GE’s proprietary calibration tool (e.g., Mark VIe Calibrator). This compensates for accuracy drift caused by long-term use and ensures compliance with industry standards (e.g., ISO 9001).

- Fault Diagnosis: If a channel fails, first check the sensor and wiring (e.g., loose connections, short circuits) before replacing the module. Use the Mark VIe DCS’s diagnostic tool to view the module’s status logs—this helps identify issues like “channel overload” or “power supply instability” without physical disassembly.

- IS200AEADH1A

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922