Description

Product Description

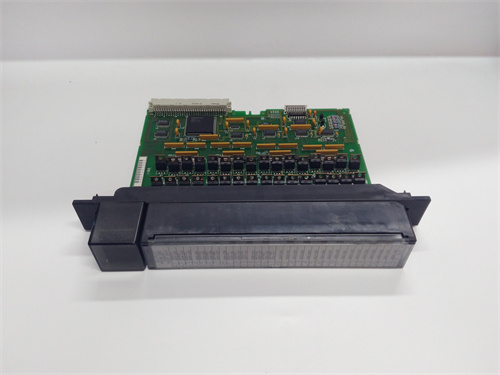

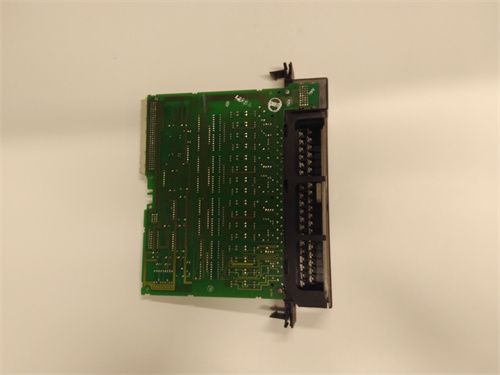

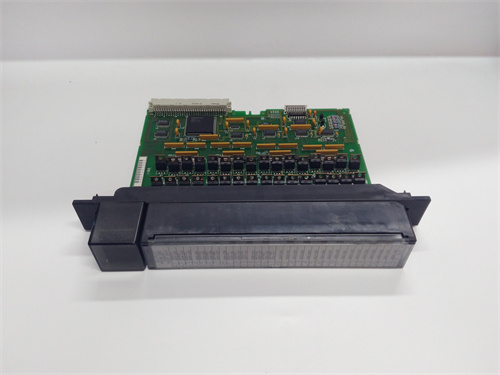

The GE IC697ALG320 is a high-density, 16-channel analog input module designed for the GE Fanuc Series 90-70 PLC system. This module serves as a critical interface, enabling the PLC to monitor real-world continuous process variables such as temperature, pressure, level, and flow by converting analog signals from field transmitters into precise digital values for the CPU. The primary function of the GE IC697ALG320 is to provide reliable, isolated acquisition of multiple analog signals, typically in the standard 4-20 mA current loop range, which is the cornerstone of process control and monitoring. Its integration into a Series 90-70 rack allows for the centralized collection of analog data from distributed sensors, forming the sensory backbone for sophisticated control strategies in industrial automation. Implementing the IC697ALG320 module expands the system’s capability from simple discrete logic to comprehensive analog process control.

Technical Parameters and Features

- Device Type: 16-channel Analog Input (AI) Module for Series 90-70 PLC.

- Input Channels: 16 single-ended analog input channels.

- Input Signal Type: Accepts 4-20 mA current loop signals (most common). It may also support other ranges like 0-20 mA or voltage inputs (0-10V DC) depending on configuration and jumpers.

- Resolution: Provides high-resolution analog-to-digital conversion, typically 12-bit resolution, offering fine granularity for accurate measurement.

- Isolation: Channels are typically group-isolated (e.g., in groups of 8) from the PLC logic and from each other, providing protection against ground loops and electrical noise.

- Input Impedance: A low input impedance (typically 250 ohms) for current signals, which is standard for interfacing with 4-20 mA transmitters.

- Update Rate: A defined scan time for updating all channels, suitable for most process monitoring applications.

- Diagnostics: Includes module-level diagnostics for faults (e.g., watchdog timer failure) and may provide channel-level status in the PLC’s I/O table.

- Configuration: Configured via the PLC programming software (Logicmaster 90, Proficy Machine Edition). Settings include signal range selection and scaling from raw counts to engineering units (e.g., psi, °C).

- Termination: Uses a removable terminal block (like the IC693TBS320) that plugs into the module’s front for field wiring.

Advantages and Key Features

- High Channel Density: The GE IC697ALG320 consolidates 16 analog points into a single module slot, offering excellent space efficiency and a lower cost per point compared to lower-density alternatives, which is ideal for applications with many sensors.

- Reliable Industrial Design: Built to the robust standards of the Series 90-70 platform, it ensures stable operation in environments with electrical noise, vibration, and temperature fluctuations common in industrial settings.

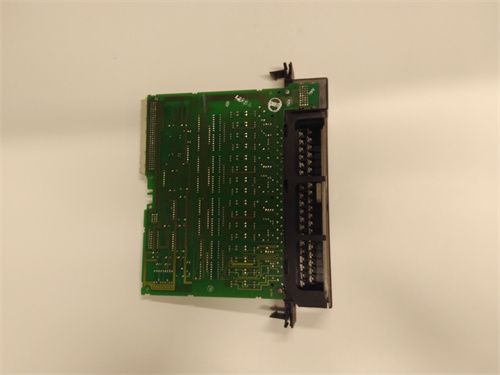

- Simplified Integration: As a native Series 90-70 module, it communicates seamlessly over the high-speed VME backplane. Configuration and data access are fully integrated into the GE programming environment, making engineering straightforward.

- Proven Compatibility: Guaranteed to work with the Series 90-70 CPU and power supply ecosystem. This avoids the integration risks and additional engineering required when using third-party analog input units.

- Legacy System Support: For the vast installed base of Series 90-70 systems, the IC697ALG320 is an essential spare part and expansion module, helping to extend the life and functionality of these reliable controllers.

Application Case Studies in Various Fields

- Water Treatment Plant: Multiple IC697ALG320 modules in a central PLC rack monitor 4-20 mA signals from pH sensors, chlorine residual analyzers, flow meters, and tank level transmitters across the treatment process.

- Food & Beverage Processing: Used in a batching system to monitor ingredient tank levels (via pressure transmitters), pasteurization temperatures (via RTD/transmitter loops), and recipe flow rates.

- Environmental Monitoring Skid: In a skid-mounted emissions monitoring system, the module reads signals from multiple gas analyzers (O2, CO, NOx) providing data for compliance reporting and combustion control.

- Factory Energy Management: Installed to monitor main electrical feeder currents (via 4-20 mA outputs from current transducers), steam flow, and compressed air pressure for plant-wide utility monitoring and optimization.

Comparison with Competing Products

Compared to using analog input modules from other contemporary PLCs or modern alternatives, the GE IC697ALG320 has specific characteristics:

- System Architecture (VME vs. others): As part of the Series 90-70’s VME bus architecture, it offers high-speed data transfer to the CPU. This differs from the proprietary backplanes of other PLCs (e.g., Allen-Bradley 1771) or newer Ethernet-based I/O.

- Density and Cost: Its 16-channel density was competitive for its time. Modern Ethernet I/O blocks can offer even higher density and distributed placement, but for a centralized Series 90-70 rack, the IC697ALG320 remains a cost-effective solution.

- Legacy vs. Modern Features: It lacks some features of modern analog modules, such as individual channel isolation, ultra-high resolution (16-bit+), or advanced onboard diagnostics for each channel. Its value is in maintaining or sparing existing systems.

Selection Advice and Important Notes

- Verify Terminal Block Requirement: The IC697ALG320 module itself does not have screw terminals. It requires a separate, compatible terminal board unit (TBU) such as the IC693TBS320. Ensure you order the correct TBU for installation.

- Configure Scaling in PLC Logic: The module outputs a raw integer value (e.g., 0-4095 for 12-bit). You must program scaling logic (SCL instructions) in the PLC ladder program to convert these counts into meaningful engineering units (e.g., 4 mA = 0 psi, 20 mA = 100 psi).

- Ensure Proper Field Wiring: Use shielded, twisted-pair cable for each analog signal. Connect the shield to ground at the PLC end only (typically at the TBU or cabinet star point) to prevent ground loops. Provide a separate isolated power supply for the 4-20 mA transmitters if needed.

- Consider Signal Loss Detection: The 4-20 mA standard allows for detection of a broken wire (0 mA) or transmitter fault (>20 mA). Implement logic in the PLC program to check for values below 4 mA (e.g., < 820 counts) to alarm on signal loss.

- Primarily for Legacy Support: The GE IC697ALG320 should be selected for expanding or maintaining existing Series 90-70 systems. For new projects, consider migrating to a newer GE platform (Rx3i, PACSystems) with more advanced I/O.

3AL79090BAAU06

FAU810 PLC

F3486027

20V4160

10V4160 PLC

509-CEB I/O

DS200IMCPG1C

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922