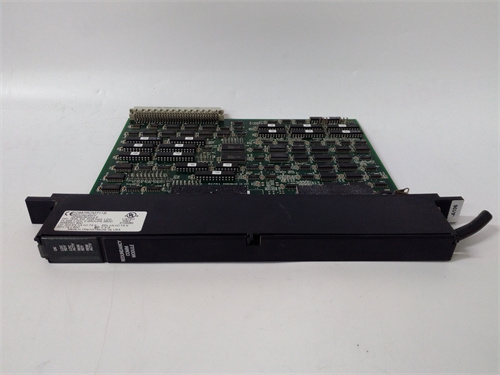

Description

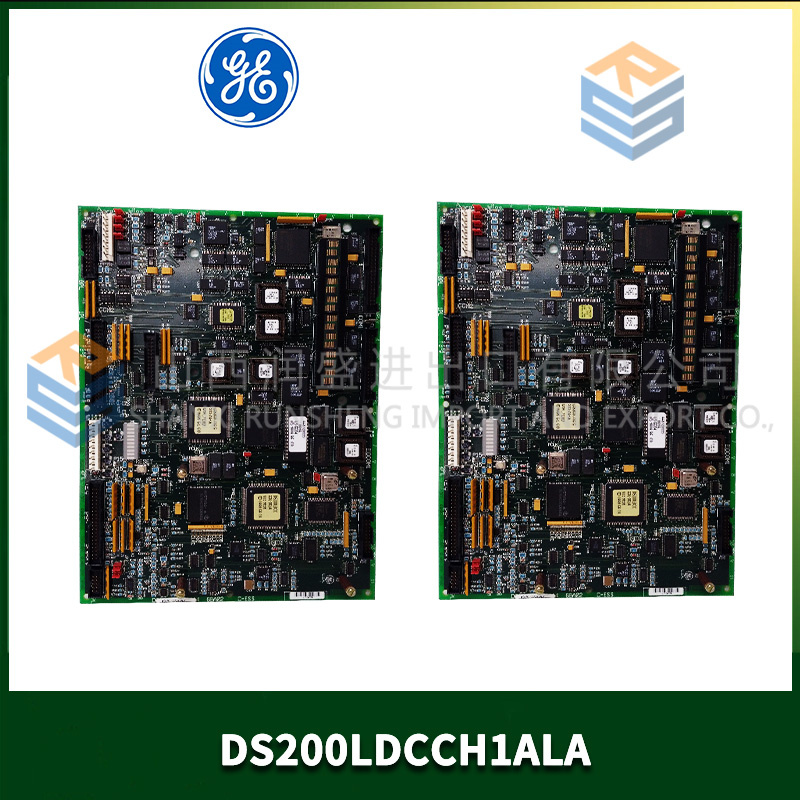

Product Description

Core Technical Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Communication Protocol | Supports Ethernet/IP (compliant with ODVA standards), including Class 1 (real-time control) and Class 3 (non-real-time data) modes |

| Network Interfaces | 2 RJ45 Ethernet ports, supporting 10/100 Mbit/s adaptive speed and Auto-MDIX automatic crossover function |

| Processing Performance | 32-bit microprocessor (200 MHz clock speed), 128 MB RAM (data cache), 64 MB Flash (configuration storage) |

| Power Requirements | Powered by the internal 5V DC bus of GE RX3i PLC, maximum power consumption current ≤ 300 mA |

| Operating Environment | Temperature: 0°C ~ +60°C; Humidity: 5% ~ 95% (no condensation); Protection Class: IP20 (for installation in enclosed control cabinets only) |

| Real-Time Performance | Data response time ≤ 1 ms in Class 1 mode, meeting industrial-grade real-time control requirements |

| Compatibility | Compatible with all GE RX3i series PLCs (e.g., IC695, IC687 series); supports third-party Ethernet/IP devices (e.g., Rockwell, Schneider products) |

| Protection Features | Ethernet ports have ±15 kV electrostatic discharge (ESD) protection, compliant with EN 61000-6-2 EMC standards |

Product Advantages and Features

-

Dual-Port Redundancy Design for Enhanced Communication Reliability

The GE IC687RCM711 is equipped with 2 independent Ethernet ports, enabling flexible “linear” or “ring” network topologies. If one communication link is interrupted due to cable breakage or switch failure, data can be automatically switched to the backup link, preventing system downtime caused by single-point faults—a critical feature for continuous-production assembly lines and unmanned warehouses.

-

Dual-Mode Ethernet/IP Support for Both Real-Time and Non-Real-Time Needs

The module supports both Class 1 and Class 3 modes of Ethernet/IP: Class 1 is used for transmitting real-time signals (e.g., motor control, emergency shutdown) to ensure millisecond-level response; Class 3 handles non-real-time tasks (e.g., PLC configuration updates, equipment fault log uploads). The two modes operate independently, ensuring control accuracy while improving data interaction efficiency.

-

Seamless Integration with GE Ecosystem to Simplify Setup

The GE IC687RCM711 requires no additional drivers or adapters and can be directly inserted into the dedicated slot of a GE RX3i PLC. The PLC automatically recognizes the module model after power-on. Using GE’s official programming software, Proficy Machine Edition, engineers can uniformly configure network parameters (e.g., IP address, data interaction cycle) without learning third-party tools, lowering integration barriers.

-

Industrial-Grade Protection for Harsh Environments

The module features an anti-interference housing, and its Ethernet ports include ESD protection to resist electromagnetic interference common in industrial sites (e.g., interference from motor startup or inverter operation). The IP20 protection rating ensures long-term stable operation in enclosed control cabinets, preventing dust and moisture from damaging internal components.

-

Comprehensive Diagnostic Functions for Easy Troubleshooting

The GE IC687RCM711 continuously monitors network status (e.g., link connectivity, data transmission error rate) and feeds diagnostic information back to the PLC and SCADA system. Engineers can check port status and fault codes via software without on-site equipment disassembly, significantly reducing troubleshooting time.

Typical Application Scenarios

-

Machinery Manufacturing: CNC Machine Cluster Control

In clusters of CNC machines controlled by multiple GE RX3i PLCs, the GE IC687RCM711 serves as the communication interface for each PLC. It uses Ethernet/IP Class 1 mode to enable real-time signal interaction between the PLC, spindle drives, and servo motors (e.g., speed commands, position feedback). Simultaneously, it uses Class 3 mode to upload equipment operation data (e.g., machining accuracy, tool life) to the central SCADA system, enabling visualized monitoring of the production process.

-

Intelligent Logistics: AGV Robot Scheduling

In unmanned warehouse systems, the GE IC687RCM711 is deployed in the AGV scheduling PLC. It sends path planning and docking commands to AGVs via Ethernet/IP Class 1 mode (with a response time ≤ 1 ms) to ensure collision-free operation of multiple AGVs. It also receives AGV data (e.g., battery level, fault alarms) via Class 3 mode and automatically triggers charging scheduling when the battery level is below the threshold.

-

Small-to-Medium Energy: Distributed PV Inverter Monitoring

In small-to-medium solar power plants, the GE IC687RCM711 connects to the GE RX3i PLC controlling inverters. It collects inverter data (e.g., output power, voltage, temperature) via Ethernet/IP Class 3 mode and uploads it to the plant monitoring system. When an inverter experiences overvoltage or overcurrent faults, the module transmits a shutdown command quickly via Class 1 mode to ensure plant safety.

Competitive Product Comparison

| Comparison Dimension | GE IC687RCM711 | Rockwell 1756-ENBT (ControlLogix Series) | Siemens CP 1616 (S7-1200/1500 Series) |

|---|---|---|---|

| Core Protocol | Ethernet/IP (Class 1/3) | Ethernet/IP (Class 1/3) | PROFINET, Modbus TCP (no Ethernet/IP support) |

| Number of Ethernet Ports | 2 (supports redundancy) | 1 (no redundancy) | 1 (no redundancy) |

| Real-Time Response Time | ≤ 1 ms (Class 1) | ≤ 1 ms (Class 1) | — (no Ethernet/IP real-time mode) |

| Compatible PLC Brand | GE RX3i Series | Rockwell ControlLogix Series | Siemens S7-1200/1500 Series |

| Operating Temperature Range | 0°C ~ +60°C | 0°C ~ +60°C | 0°C ~ +60°C |

| Mean Time Between Failures (MTBF) | >100,000 hours | ~90,000 hours | ~80,000 hours |

Selection Suggestions and Precautions

Selection Suggestions

-

Prioritize Compatibility with the GE RX3i PLC Ecosystem

If your existing automation system is centered on GE RX3i series PLCs, the GE IC687RCM711 is the optimal choice—it achieves hardware compatibility and software integration without additional adaptation, avoiding stability issues caused by cross-brand 适配.

-

Choose Port Topology Based on Communication Needs

For systems requiring continuous operation (e.g., chemical assembly lines, 24/7 automotive parts production lines), use the GE IC687RCM711’s dual ports to build a ring-shaped redundant network. For intermittently operated equipment (e.g., small packaging machines), a single-port linear network suffices to reduce costs.

-

Confirm Environmental Temperature and Installation Scenario

The module only supports an operating temperature range of 0°C ~ +60°C and has an IP20 protection rating. Ensure it is installed in an enclosed, well-ventilated control cabinet, and avoid direct exposure to high temperatures, heavy dust, or humid environments. For scenarios with temperatures outside 0°C ~ +60°C (e.g., outdoor solar power plants, low-temperature cold storage), select a more weather-resistant GE model (e.g., IC687RCM712).

Precautions

-

Strictly Follow Wiring Specifications

During installation, ensure the GE IC687RCM711 is powered by the 5V DC bus of the GE RX3i PLC—do not directly connect it to external 220V AC or 24V DC power, as this will damage the module. Use industrial-grade CAT 5e or higher Ethernet cables, and ensure the link length does not exceed 100 meters (add an industrial switch if it does).

-

Back Up Existing Parameters Before Configuration

Before configuring the GE IC687RCM711 via Proficy Machine Edition, back up the PLC’s existing programs and network configurations to avoid communication interruptions between the PLC and other devices due to incorrect parameter modifications.

-

Regularly Check Communication Status and Port Connections

It is recommended to check the GE IC687RCM711’s port status (e.g., link connectivity, number of error frames) via the SCADA system or Proficy software monthly. Every quarter, open the control cabinet to inspect whether Ethernet cable connectors are loose and whether the module is dissipating heat properly, preventing communication anomalies caused by physical faults.

-

Electrostatic Protection Measures

Before plugging in or unplugging the GE IC687RCM711, engineers must wear an anti-static wristband to avoid damaging the module’s Ethernet ports or internal chips with human electrostatic discharge. Store the module in anti-static packaging when not in use, and do not contact it directly with metal objects.

IC687RCM711

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922