Description

Product Description

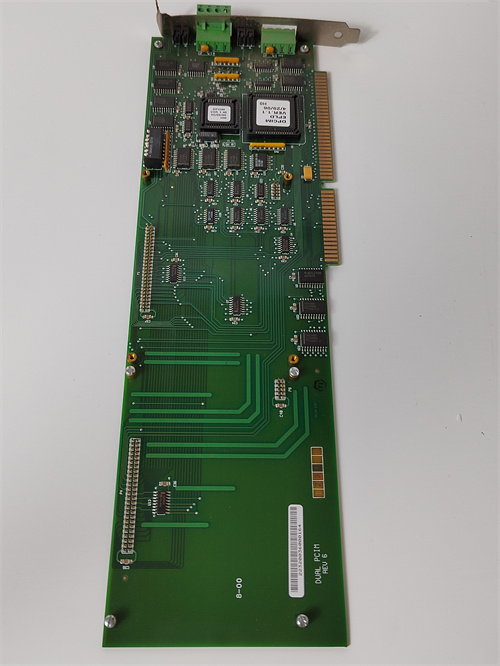

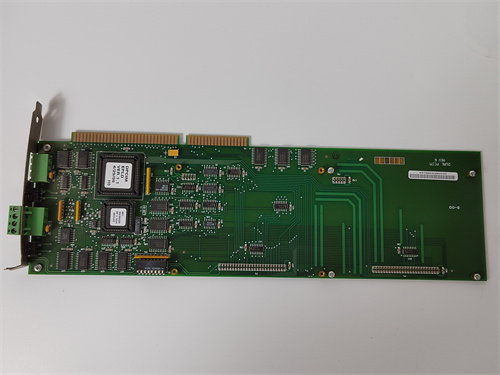

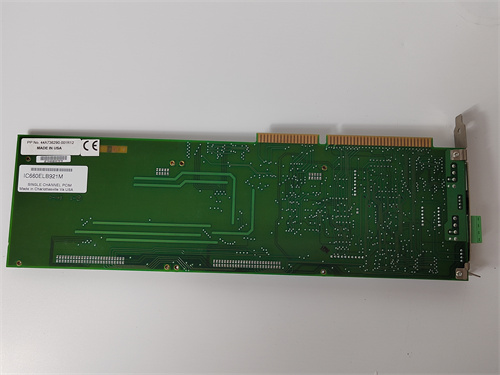

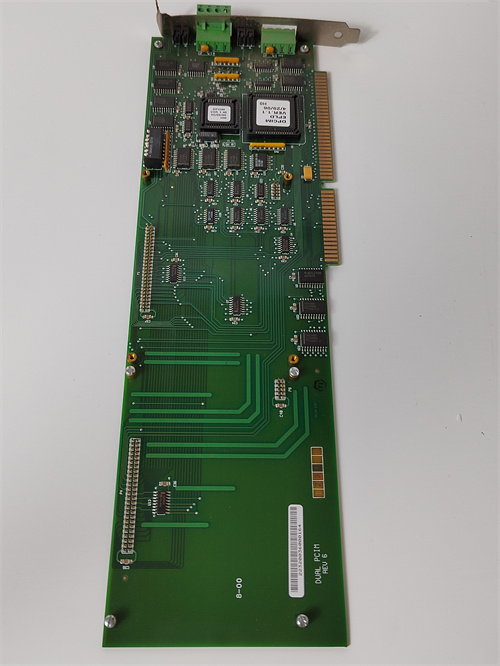

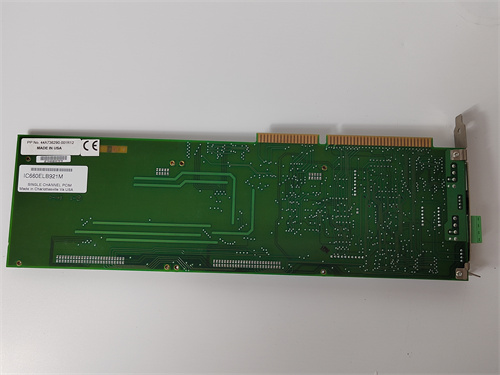

The GE IC660ELB921M is a specialized high-density digital input module for the GE Fanuc Series 90-30 programmable logic controller (PLC), part of the Genius I/O distributed I/O system. This module is a Genius Bus Discrete Input Block designed to interface a large number of field devices to the PLC via the Genius communication network. Its primary function is to convert the state (ON/OFF) of up to 32 discrete sensors—such as limit switches, pushbuttons, and proximity sensors—into data that is transmitted over the Genius bus to the central controller. By providing 32 isolated input channels in a compact, remote block, the GE IC660ELB921M allows for significant I/O expansion away from the main PLC rack, reducing wiring costs and simplifying system architecture. The reliable operation of machine sequencing and status monitoring across a large area often depends on the accurate performance of such distributed I/O blocks. Integrating the GE IC660ELB921M effectively extends the reach and capability of a Series 90-30 system, enabling true distributed control.

Product Parameters

- PLC Family: GE Fanuc Series 90-30 (via Genius Bus).

- I/O System: Genius Distributed I/O.

- Module Type: 32-point Genius Bus Discrete Input Block.

- Number of Channels: 32 isolated input channels.

- Input Type: Sourcing or Sinking, specific to the variant (likely 24V DC).

- Input Voltage: 24V DC nominal.

- Isolation: Channel-to-channel and channel-to-bus isolation.

- Status Indicators: Per-channel LED status indicators (typically in groups of 4 or 8) and module status LEDs for power, communication, and fault.

- Communication: Interfaces with the Series 90-30 PLC via the Genius bus (153.6 kbaud) through a Genius Bus Controller (GBC) module like the IC693CMM321.

- Addressing: Configured via a rotary switch on the module to set its unique Genius device address (0-31).

- Mounting: Designed for DIN-rail or panel mounting in a remote location.

- Power Supply: Requires an external 24V DC power source for the field inputs.

Advantages and Features

- High-Density Remote I/O: Provides 32 inputs in a single, compact block that can be located up to 7500 feet from the controller, drastically reducing home-run wiring.

- Clear Diagnostic Visibility: Grouped per-channel LEDs allow for quick visual troubleshooting of field device status directly at the I/O block.

- Robust Communication: The Genius bus protocol offers deterministic, noise-immune communication suitable for industrial environments.

- Simplified System Expansion: Adding I/O points is as simple as adding another Genius block to the bus and setting a unique address, without modifying the central PLC rack.

- Proven Reliability: As a core component of the widely installed Genius system, the GE IC660ELB921M has a long history of dependable performance.

Application Cases in Application Fields

- Automated Assembly Lines: Distributed along a conveyor line to read sensors from numerous stations (part present, cylinder extended, guard closed).

- Large Material Handling Systems: Placed near conveyor zones, sorters, and palletizers to monitor photo-eyes, limit switches, and motor feedback contacts.

- Water Treatment Plants: Installed in remote pump houses or filter buildings to monitor pump status, valve limits, and level switches.

- Packaging Machinery: Used to consolidate inputs from multiple sensors on a large machine into a single communication drop.

Comparisons with Competing Products

- Vs. GE Series 90-30 Rack-based Digital Input Modules (e.g., IC693MDL654): Rack-based modules are centralized. The GE IC660ELB921M is part of a distributed I/O architecture, offering superior wiring savings and flexibility for geographically spread I/O points.

- Vs. Allen-Bradley Point I/O or Flex I/O: These are Allen-Bradley’s distributed I/O systems. The GE IC660ELB921M serves the same logical function but within the GE Genius ecosystem. They are not interchangeable.

- Vs. Modern Ethernet-based Remote I/O (e.g., GE VersaMax IP): Modern systems use Ethernet/IP or PROFINET. The GE IC660ELB921M represents an older, serial-based technology. Modern solutions offer higher bandwidth and IT integration, but the Genius system is renowned for its simplicity, determinism, and long-distance capability.

Selection Suggestions and Precautions

- Genius Bus Network Planning: Each GE IC660ELB921M block must have a unique address set via its rotary switch. Duplicate addresses will cause bus failure. Plan the addressing scheme carefully.

- Power Supply Calculation: The external 24V DC power supply for the block must be sized to handle the inrush and steady-state current of all 32 connected sensors simultaneously.

- Correct Wiring and Fusing: Use appropriately sized wire. It is good practice to fuse groups of inputs or the entire block’s power feed to protect the module from field-side short circuits.

- Bus Termination: The Genius bus must be properly terminated at both physical ends of the daisy chain with terminating resistors to ensure reliable communication.

- Configuration in PLC Software: The block must be correctly declared and its I/O points mapped in the Series 90-30 hardware configuration within the programming software (e.g., Proficy Machine Edition).

ABB 3HAB8440-1 PLC

3HAC17343-1 ABB PLCPLC

ABB 3HAC1855-1

ABB 3HAC021456-001

3HAC031851-001 PLC

ABB 3HAC029157-001 I/O

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922