Description

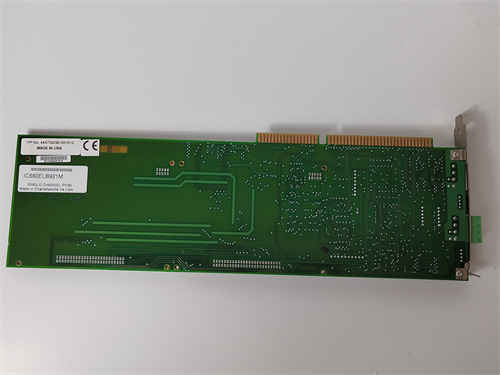

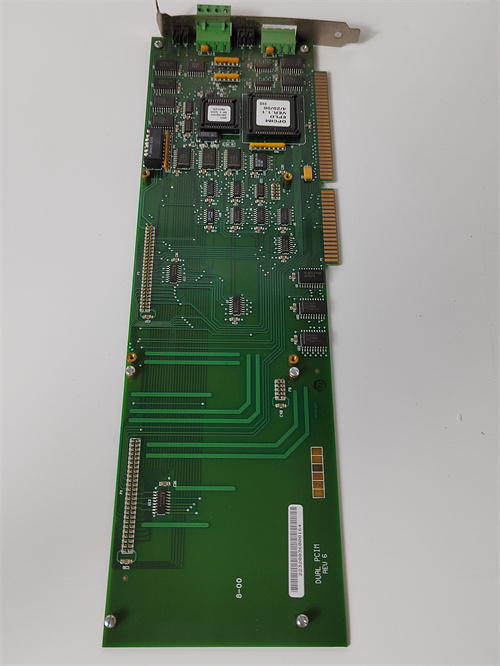

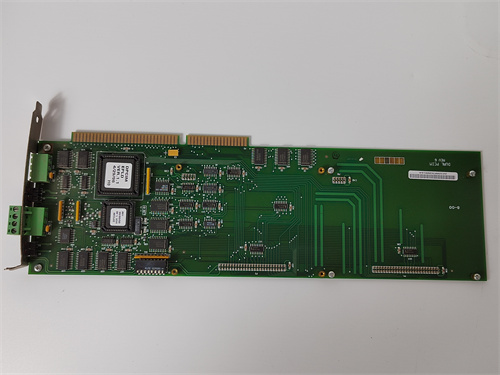

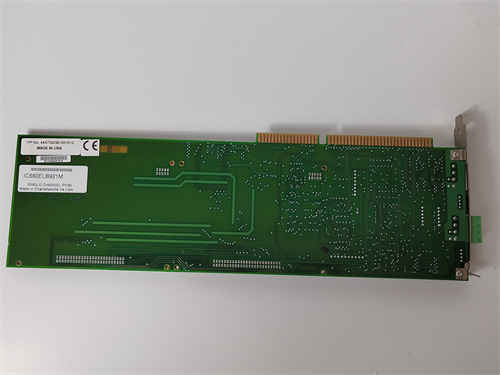

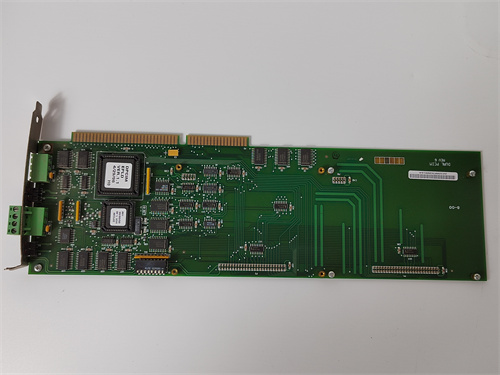

Product Description

Product Parameters

- Module Type: Single-slot Genius I/O PC Interface Module (PCIM), dedicated for GE Fanuc PACSystems RX3i

- Working Voltage: DC 5V, maximum operating current 400mA

- Power Consumption: 2.5W, low power industrial design

- Communication Protocols: RS-232, RS-485; compatible with Genius I/O bus protocol

- Communication Baud Rate: 38.4K, 76.8K, 153.6K standard/extended baud rate

- I/O Capacity: 8000 input & 8000 output address locations; single-channel 1LS TTL load support

- Working Temperature: -40°C ~ +70°C, wide temperature adaptation for harsh industrial conditions

- Protection Grade: IP65, dustproof and waterproof for on-site cabinet/on-site installation

- Installation Method: Standard DIN 35mm rail installation; compatible with ISA slot

- Dimension: 120mm×75mm×45mm, compact single-slot structure

- Weight: Approx. 0.2kg, lightweight for easy installation and disassembly

- Memory Requirement: 4 bytes of host memory for data interaction

- Bus Compatibility: Manages up to 30 Genius I/O bus devices simultaneously

Advantages and Features

-

Genius I/O Bus Deep Compatibility

GE IC660ELB921M is a customized PCIM for GE Fanuc’s Genius I/O bus system, fully compatible with all GE original bus controllers and handheld monitors. It can directly access the Genius I/O network without additional conversion modules, ensuring zero communication delay and data loss.

-

Multi-Baud Rate & Multi-Protocol Communication

Supporting RS-232/RS-485 dual serial ports and three adjustable baud rates, the module can flexibly match different host computer and field device communication requirements, and realize seamless data transmission with IBM PC/XT/AT and other mainstream industrial computers.

-

Super Harsh Environment Adaptability

With IP65 high protection grade and -40°C~+70°C ultra-wide working temperature range, the module is made of industrial-grade anti-corrosion and anti-vibration components, which can stably operate in high temperature, humidity, dust and strong electromagnetic interference industrial scenes such as on-site equipment room and production line.

-

Flexible Independent Configuration

Equipped with GE original dedicated configuration software, the module’s daughterboard can be configured independently from the motherboard. It supports input-only/output-only dual working modes, and can be quickly adjusted according to on-site data acquisition and control needs without modifying the host system program.

-

Compact & High-Efficiency Design

The single-slot compact structure and DIN rail/ISA slot dual installation methods save a lot of control cabinet space; the 0.2kg lightweight design and plug-and-play structure enable quick replacement without professional tools, greatly reducing maintenance downtime.

-

Powerful Bus Device Management Capacity

It can manage up to 30 Genius I/O bus devices at the same time, with independent fault management and initialization functions for each device. It can real-time monitor the running status of bus devices and realize quick fault location, improving the maintainability of the whole control system.

Application Fields and Application Cases

Core Application Fields

Typical Application Cases

- A North American petrochemical plant: The original communication module of the refinery’s Genius I/O bus system failed, resulting in disconnection between the upper monitoring computer and the on-site flow control valve. After replacing GE IC660ELB921M, the system realized real-time data transmission at 153.6K baud rate immediately, and the anti-interference ability was significantly improved. The system has been operating without fault for more than 8,500 hours, completely solving the problem of communication interruption caused by generic modules.

- A European thermal power plant: In the upgrade of the power plant’s auxiliary system monitoring, GE IC660ELB921M was adopted in batches as the PC interface module. It perfectly matches the original GE PACSystems RX3i system and IBM industrial computer, realizing unified management of 28 on-site sensor devices. The installation and commissioning cycle is shortened by 70% compared with using general communication modules, and the data transmission accuracy is increased to 99.99%.

- An Asian food and beverage enterprise: In the digital transformation of the beverage production line, GE IC660ELB921M was selected to connect the on-site PLC and the upper SCADA system. Its IP65 protection grade and low power consumption adapt to the high-humidity production environment of the factory, and the flexible configuration function meets the mixed requirements of production line data input and control output. The production line’s automation control efficiency is increased by 20%.

Comparison with Competing Products

| Comparison Dimension | GE IC660ELB921M | Generic Industrial PC Interface Module | Other Brands’ Original I/O Bus Interface Module |

|---|---|---|---|

| Bus Compatibility | Full compatibility with GE Genius I/O bus, plug-and-play | Secondary protocol conversion required, easy to have communication delay | Only compatible with its own brand bus system, incompatible with GE equipment |

| Communication Performance | 3 baud rates adjustable, support RS-232/RS-485 | 1-2 fixed baud rates, single communication port | 2 baud rates adjustable, no Genius protocol support |

| Protection Grade | IP65, dustproof and waterproof | IP20-IP40, only for cabinet installation | IP54, lower protection than the product |

| Working Temperature | -40°C ~ +70°C, ultra-wide adaptation | -20°C ~ +60°C, limited harsh environment adaptability | -30°C ~ +65°C, narrower temperature range |

| Device Management Capacity | Manage 30 bus devices simultaneously | ≤10 bus devices, simple management function | ≤20 bus devices, no independent fault management |

| Installation Method | DIN rail + ISA slot, dual installation | Single DIN rail installation, poor compatibility | Single slot installation, no DIN rail support |

| MTBF | ≥100,000 hours | About 40,000-60,000 hours | ≥70,000 hours, 30% higher purchase cost |

Selection Suggestions and Precautions

Selection Suggestions

- If the on-site automation control system is GE Fanuc’s Genius I/O bus and PACSystems RX3i series, GE IC660ELB921M is the first choice to avoid communication compatibility problems of generic modules and ensure the stability of the whole system.

- For industrial scenes that need to connect IBM PC/XT/AT host computers with field I/O bus devices, select GE IC660ELB921M for its multi-protocol and multi-baud rate communication features to meet diverse communication needs.

- For on-site installation scenarios with high humidity, dust and extreme temperature (such as petrochemical on-site and food production lines), priority is given to GE IC660ELB921M with IP65 protection grade and wide temperature adaptability.

- For GE system expansion that needs to manage multiple bus devices, GE IC660ELB921M with 30 devices management capacity is the optimal solution, which can reduce the number of modules and save system cost.

Precautions

- Before installation and commissioning, carefully read the original installation manual of GE IC660ELB921M, and strictly follow the manual requirements for wiring and baud rate setting. Cut off the power supply of the host computer and bus system before plugging and unplugging the module to avoid burning the module or damaging the bus controller.

- When configuring the module, use GE original dedicated configuration software to set the working mode (input-only/output-only) and baud rate, and do not modify the EEPROM address at will to avoid address conflict and communication failure.

- In daily maintenance, regularly clean the dust and dirt on the surface and interface of GE IC660ELB921M. Use dry and dust-free compressed air to purge for cabinet installation, and wipe the surface with anti-static cloth for on-site installation to avoid poor contact caused by dust accumulation.

- When wiring the communication port, use shielded serial cables and reliably ground the shield layer to reduce electromagnetic interference and ensure the stability of data transmission between the module and the host computer/field devices.

- When storing spare parts, place GE IC660ELB921M in a dry, normal temperature and anti-static environment. The storage temperature is controlled at 0°C ~ +35°C, and the relative humidity is ≤70% to avoid aging of electronic components and oxidation of the interface.

- After replacing the module, carry out bus communication test and device connection test in turn, confirm that all bus devices can be monitored and controlled normally, and then put the whole system into on-load operation to avoid system paralysis caused by untested operation.

- It is strictly forbidden to use GE IC660ELB921M beyond the rated voltage and current range, and do not disassemble the module’s shell and daughterboard without authorization, otherwise it will cause permanent damage to the module and invalid the original quality assurance.

SC520 PLC

81EU01E-E PLC

IS2020ISUCG1A PLC

IS2020ISUCG3A PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922