Description

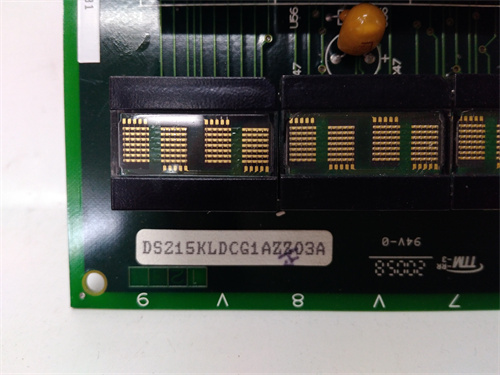

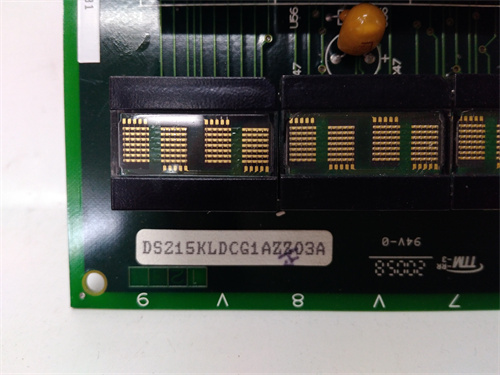

GE DS215KLDCG1AZZ03A: Core Controller Module for GE Speedtronic Turbine Automation Systems

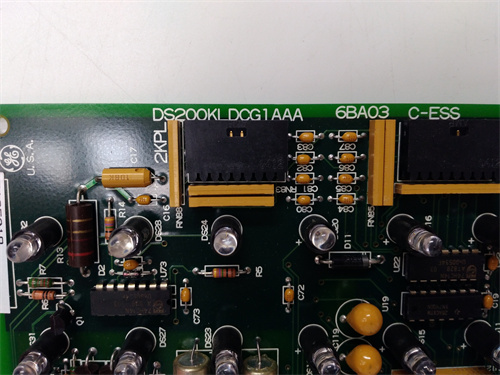

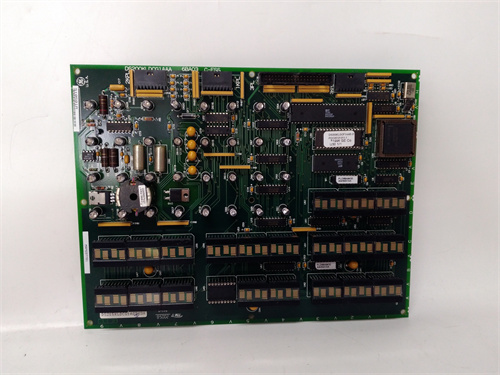

GE DS215KLDCG1AZZ03A (Product Link: [Insert Official GE Product Page Link Here]) is a high-performance, application-specific controller module developed by General Electric (GE) exclusively for the GE Speedtronic automation platform. Designed to manage and monitor critical operations of gas turbines, steam turbines, and combined-cycle power units, GE DS215KLDCG1AZZ03A serves as the “brain” of power generation systems—ensuring stable, safe, and efficient operation in harsh industrial environments such as thermal power plants, large-scale industrial 自备电站 (captive power plants), and combined-cycle power plants (CCPPs). Unlike universal PLCs, this module is engineered with turbine-specific control logic and redundancy features, making it indispensable for mission-critical energy infrastructure where unplanned downtime could result in millions of dollars in losses.

1. Core Functions & Product Positioning

GE DS215KLDCG1AZZ03A is tailored to address the unique challenges of turbine control, integrating three key capabilities that set it apart from standard automation components:

- Comprehensive Signal Processing: It supports up to 64 analog inputs (AI) for precision measurements (e.g., turbine speed, steam pressure, rotor temperature—with ±0.05% accuracy), 128 digital inputs/outputs (DI/DO) for discrete control (e.g., valve status monitoring, alarm triggering—24V DC/120V AC), and 8 frequency inputs (FI) for speed sensing (0–10 kHz). This enables real-time data capture across the entire turbine lifecycle, from startup and load ramping to full-load operation and shutdown.

- Turbine-Optimized Control Logic: Equipped with GE’s proprietary adaptive PID algorithms and built-in turbine mathematical models, GE DS215KLDCG1AZZ03A automatically adjusts control parameters based on load changes (e.g., transitioning from idle to rated power). It prevents fluctuations in speed or steam pressure and predicts rotor temperature rises to avoid exceeding safe operating limits—extending turbine lifespan.

- High-Reliability Redundancy: The module adopts a “2-out-of-2” or “2-out-of-3” voting architecture. If one signal processing channel fails, a backup channel seamlessly takes over, eliminating false trips of emergency systems (e.g., unnecessary turbine shutdowns). A built-in self-diagnostic system continuously monitors internal components (processor, memory, interfaces) and sends fault data to SCADA systems, allowing proactive maintenance.

2. Key Technical Specifications & Performance Advantages

Technical Specifications

| Parameter Category | Details |

|---|---|

| Processor & Memory | 500 MHz Digital Signal Processor (DSP); 1 GB DDR4 RAM; 32 GB Flash Storage (for configuration/history) |

| I/O Interfaces | 64x AI (4–20 mA/0–10 V DC); 128x DI/DO (2 A output); 8x FI (0–10 kHz) |

| Communication Protocols | 2x Gigabit Ethernet (Modbus TCP, IEC 61850); 4x RS485; GE Speedtronic Link (proprietary) |

| Environmental Resistance | Operating Temp: 0–60°C; Humidity: 5–95% (non-condensing); Vibration: IEC 60068-2-6 (10–500 Hz, 5G) |

| Safety Certifications | UL 508, CSA C22.2 No.14, IEC 61508 SIL 3, ATEX Zone 2 |

Performance Advantages

- Millisecond-Level Response: With signal processing latency ≤1 ms, GE DS215KLDCG1AZZ03A rapidly addresses critical events (e.g., sudden speed spikes or steam pressure drops), preventing turbine damage.

- Long-Term Data Logging: It stores 2 years of operational data at 1-ms intervals, enabling post-incident analysis (e.g., troubleshooting unplanned shutdowns) and compliance with regulatory reporting requirements.

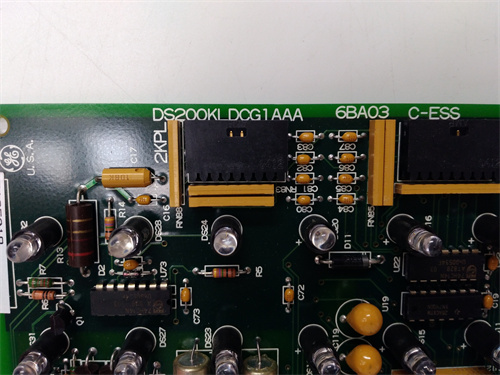

- Seamless GE Ecosystem Integration: It works seamlessly with other GE Speedtronic components, such as the GE DS200LPPAG1AAA (I/O module), GE PQMII-T20-C-A (power quality analyzer), and GE CIMPLICITY (SCADA software), eliminating the need for custom adapters.

3. Typical Application Scenarios

GE DS215KLDCG1AZZ03A is exclusively used in energy sector turbine control, with three primary applications:

- Gas Turbine (GTU) Control: In CCPPs, GE DS215KLDCG1AZZ03A regulates gas nozzle position and combustion chamber temperature while monitoring rotor vibration (to avoid resonance). It balances efficiency and safety across varying load conditions.

- Steam Turbine (PTU) Control: For thermal power plant PTUs, the module monitors main steam pressure (up to 24 MPa) and exhaust temperature (up to 565°C). It uses PID logic to adjust governor valve openings, matching steam flow to electricity output.

- Combined-Cycle Unit (CCPP) Synchronization: In “GTU + PTU” CCPPs, GE DS215KLDCG1AZZ03A coordinates load distribution between the two turbines. It maximizes the use of high-temperature exhaust gas from the GTU (to generate steam for the PTU), boosting overall efficiency to over 60%.

4. Competitor Comparison: Core Competitive Edge

When compared to turbine controllers from Siemens and ABB, GE DS215KLDCG1AZZ03A excels in application fit and reliability:

| Comparison Dimension | GE DS215KLDCG1AZZ03A | Siemens S7-400 FH (Turbine-Specific) | ABB AC800M HI (High-Integrity) |

|---|---|---|---|

| Safety Integrity Level | SIL 3 (2-out-of-3 voting) | SIL 2 (1-out-of-2 voting) | SIL 3 (2-out-of-3 voting) |

| Signal Handling Capacity | 64 AI + 128 DI/DO | 32 AI + 64 DI/DO | 48 AI + 96 DI/DO |

| Turbine Algorithm Fit | Built-in GE turbine models + adaptive PID | Universal PID (custom turbine logic required) | Basic turbine algorithms (ABB unit adaptation needed) |

| Response Latency | ≤1 ms | ≤5 ms | ≤2 ms |

| Ecosystem Compatibility | Full GE Speedtronic integration | Limited Siemens T3000 compatibility | ABB Symphony compatibility (special drivers required) |

GE DS215KLDCG1AZZ03A outperforms competitors in signal capacity, response speed, and GE ecosystem integration—making it the ideal choice for users with GE turbine infrastructure.

5. Selection Guidelines & Usage Precautions

Selection Guidelines

- Equipment Brand Alignment: Use GE DS215KLDCG1AZZ03A with GE Speedtronic systems or GE-manufactured turbines (e.g., GE 9HA, 7FA gas turbines) to avoid compatibility issues.

- Unit Size: Choose this module for turbines with a capacity ≥100 MW. Smaller units may use lower-tier GE controllers for cost efficiency.

- Safety Requirements: Select GE DS215KLDCG1AZZ03A for hazardous scenarios (e.g., gas-fired combustion chambers) that require SIL 3 certification.

Usage Precautions

- Installation: Mount only in GE Speedtronic cabinets, follow TN-S grounding standards (to reduce EMI), and ensure ≥10 air changes per hour (to prevent overheating).

- Configuration: Restrict parameter adjustments (e.g., PID gains, alarm thresholds) to GE-certified engineers. Never modify built-in turbine models—this risks control instability.

- Maintenance: Conduct bi-annual inspections (clean vents, check connector tightness) and update firmware exclusively from GE’s official portal.

- Spare Parts: Replace faulty units only with genuine GE DS215KLDCG1AZZ03A parts. Third-party alternatives may compromise redundancy and safety.

In summary, GE DS215KLDCG1AZZ03A is a purpose-built controller that delivers unmatched reliability, speed, and compatibility for GE Speedtronic turbine systems. It is the backbone of critical power generation infrastructure, ensuring safe, efficient, and continuous operation in the most demanding energy environments.

DS215KLDCG1AZZ03A

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922