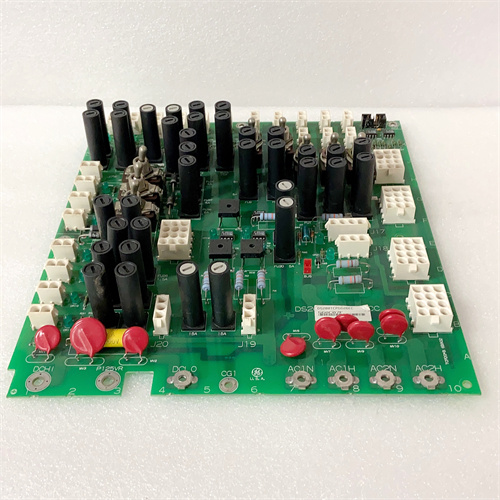

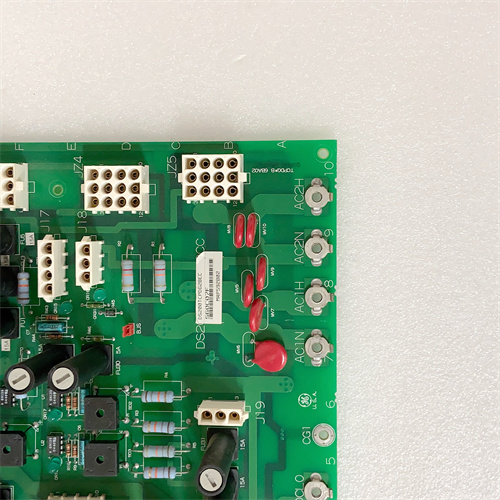

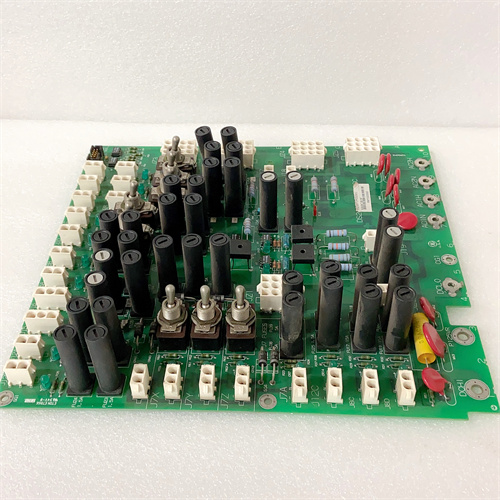

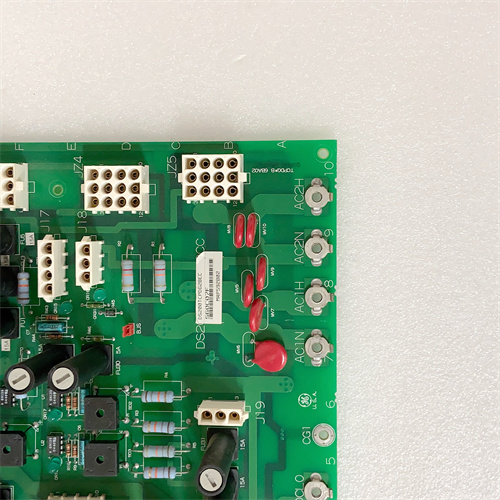

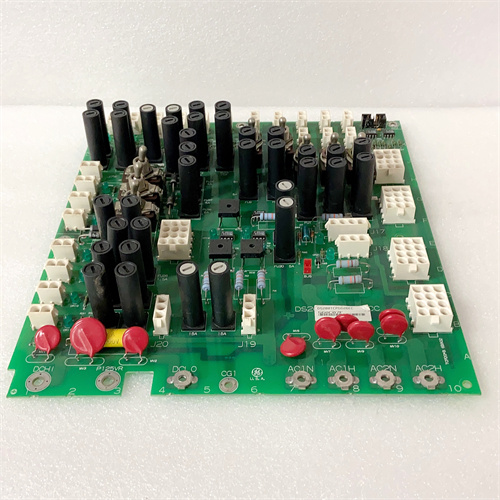

Description

1. Product Overview

2. Product Parameters

2.1 Core Encoder Interface Specifications

- Encoder Types Supported: Quadrature incremental encoders (TTL/HTL), absolute encoders (SSI, BISS-C), resolver inputs (11V/26V)

- Number of Encoder Channels: 4 (2 primary, 2 redundant)

- Maximum Input Frequency: 1 MHz (quadrature encoders), 500 kHz (absolute encoders)

- Resolution Support: Up to 10,000 pulses per revolution (PPR) for incremental encoders; 24-bit for absolute encoders

- Signal Conditioning: Built-in low-pass filtering, differential signal reception, noise rejection (>80dB)

- Speed Measurement Range: 0–100,000 RPM (turbine shaft speed)

2.2 Electrical & System Parameters

- Power Supply: 5V DC (logic) + 24V DC (encoder power), dual redundant inputs

- Power Consumption: 3W (typical, full load)

- Isolation: 2500V AC encoder inputs to logic; 1500V AC channel-to-channel

- Diagnostic Features: Encoder signal loss detection, phase error monitoring, overspeed alert outputs (dry contact), input noise level monitoring

- Redundancy: 2-out-of-3 voting for encoder inputs (configurable); hot standby for primary/redundant channels

2.3 Environmental & Mechanical Parameters

- Operating Temperature: -40°C to +75°C (extended extreme range)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: 5-500Hz, 5g (IEC 60068-2-6, turbine environment compliant)

- Shock Resistance: 50g (11ms half-sine wave, IEC 60068-2-27)

- Form Factor: Controller chassis-mounted board (Mark V/VI compatible), 150mm × 120mm × 30mm

- Weight: 0.4kg

2.4 Certifications & Compliance

- Industry Certifications: CE, UL/cUL 508, ATEX Zone 2, IECEx

- Safety Ratings: IEC 61508 SIL 2 (for overspeed protection)

- Turbine Standards: API 612 (steam turbines), API 670 (machinery protection), ISO 13849-1

- EMI/EMC Compliance: EN 55032 (Class A), EN 61000-6-2 (industrial immunity), EN 61000-4-3 (radiated immunity)

3. Advantages & Features

- Ultra-Precise Speed & Position Sensing: GE DS200TCQAG1B supports up to 10,000 PPR incremental encoders and 24-bit absolute encoders, delivering ±0.01 RPM speed measurement accuracy—critical for maintaining grid frequency compliance and preventing turbine overspeed events.

- Enhanced Noise Immunity: Built-in differential signal reception and >80dB noise rejection enable GE DS200TCQAG1B to process encoder signals reliably in high-electrical-noise turbine environments (e.g., near generators or high-voltage wiring), eliminating signal distortion and false speed readings.

- Redundant Encoder Inputs: 2-out-of-3 voting and hot standby channels ensure GE DS200TCQAG1B maintains speed feedback even if a primary encoder fails, providing fail-safe operation for mission-critical turbine control loops.

- Turbine-Grade Durability: -40°C to +75°C operating temperature range and 5g vibration resistance allow GE DS200TCQAG1B to perform in extreme turbine room conditions, including arctic power plants and desert pipeline compressor stations.

- Native GE Controller Integration: GE DS200TCQAG1B is pre-configured for Mark V/VI turbine control systems, with plug-and-play compatibility that eliminates custom signal conditioning and reduces commissioning time by up to 30%.

4. Application Fields & Cases

4.1 Application Fields

- Combined-Cycle Power Plants: Gas turbine speed regulation, generator synchronization, rotor position monitoring

- Fossil Fuel Power Plants: Steam turbine overspeed protection, governor control, shaft position sensing

- Pipeline Compressors: Turbine/compressor shaft speed monitoring, anti-surge control, mechanical overspeed protection

- Industrial Turbines: Compressor/pump driver turbine speed control, rotor synchronization, load balancing

4.2 Typical Cases

- Gas Turbine Grid Compliance (Europe): A French utility deployed GE DS200TCQAG1B in 30 combined-cycle power plant turbine controllers to maintain ±0.1 RPM speed accuracy, ensuring compliance with European grid frequency standards (50Hz ±0.1Hz). This eliminated $200,000 in annual regulatory penalties.

- Steam Turbine Overspeed Protection (USA): A U.S. coal-fired power plant used GE DS200TCQAG1B in Mark V steam turbines to monitor rotor speed and trigger emergency shutdowns if overspeed conditions are detected. Redundant encoder inputs prevented a false shutdown during a primary encoder failure, saving $150,000 in lost generation.

- Pipeline Compressor Speed Control (Middle East): A Qatar natural gas pipeline operator integrated GE DS200TCQAG1B into compressor turbine control systems to track shaft speed and optimize anti-surge valve actuation. The board’s noise immunity eliminated speed signal distortion near high-voltage compressors, reducing anti-surge events by 25%.

5. Competitive Comparison

| Parameter | GE DS200TCQAG1B | Competitor A (Turbine Encoder Interface) | Competitor B (Generic Encoder Card) |

|---|---|---|---|

| Maximum Encoder PPR | 10,000 | 5,000 | 2,000 |

| Speed Accuracy | ±0.01 RPM | ±0.1 RPM | ±0.5 RPM |

| Noise Rejection | >80dB | >60dB | >40dB |

| Redundancy Support | 2-out-of-3 Voting | Cold Standby Only | None |

| Turbine Compatibility | Mark V/VI | Mark VI Only | None |

6. Selection Suggestions & Precautions

6.1 Selection Suggestions

- Precision Speed Control Applications: Choose GE DS200TCQAG1B for gas/steam turbines requiring ±0.1 RPM speed regulation (grid compliance) or overspeed protection (SIL 2 safety rating).

- High-Noise Turbine Environments: Opt for GE DS200TCQAG1B for installations near generators, high-voltage wiring, or compressors—its enhanced noise immunity eliminates signal distortion.

- Mark V/VI Turbine Control Systems: Select GE DS200TCQAG1B to leverage native compatibility with GE’s flagship turbine controllers, avoiding custom signal conditioning hardware.

6.2 Precautions

- Installation Guidelines:

- Install GE DS200TCQAG1B only in compatible Mark V/VI controller chassis; route encoder cables away from high-voltage wiring (≥480V) and use shielded twisted-pair cables to minimize noise interference.

- Ground encoder cable shields at both the board and encoder ends (per GE recommendations) to maximize noise rejection.

- Configuration Notes:

- Calibrate encoder resolution and speed measurement range via GE Diagnostic Tool before commissioning—incorrect settings will cause speed measurement errors.

- Enable 2-out-of-3 voting for overspeed protection channels (per GE safety guidelines) to prevent false shutdowns and ensure fail-safe operation.

- Troubleshooting:

- For speed signal loss: Check encoder wiring (shield continuity, loose connections), verify encoder power (24V DC), and inspect for signal noise via the board’s diagnostic tools.

- For phase errors: Confirm encoder phase alignment (A/B/Z signals) with the turbine shaft; replace faulty encoders if phase mismatch persists.

- Maintenance:

- Inspect encoder cables and connectors quarterly (vibration can cause loosening) and clean board input terminals with approved electrical contact cleaner to prevent corrosion.

- Recalibrate speed measurement accuracy annually using a certified tachometer to maintain ±0.01 RPM precision.

TRICON3503E PLC

TRICON3700A PLC

SCHNEIDER140DAI55300 PLC

IPSYS01 PLC

IEPAS02 PLC

IEPAS01 PLC

IPFLD24 PLC

IMCIS02 PLC

IMMFP01 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922 Wechat:+86 15343416922

Wechat:+86 15343416922