Description

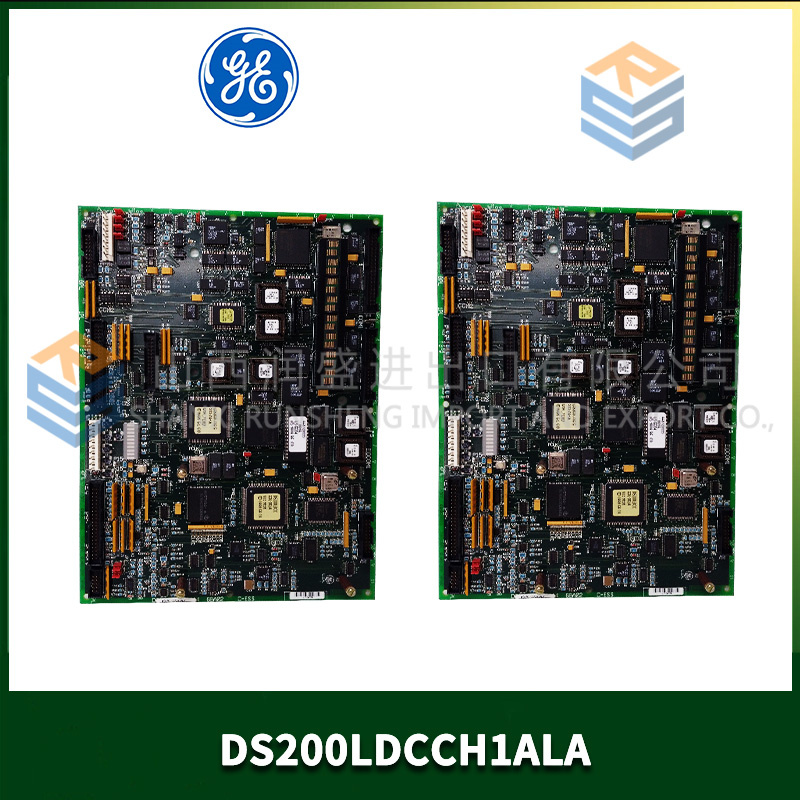

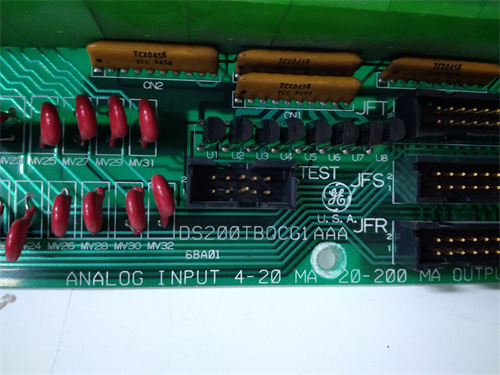

1. Product Overview

2. Product Parameters

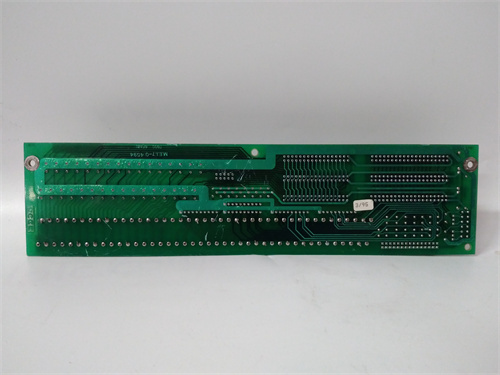

2.1 Core Connection Specifications

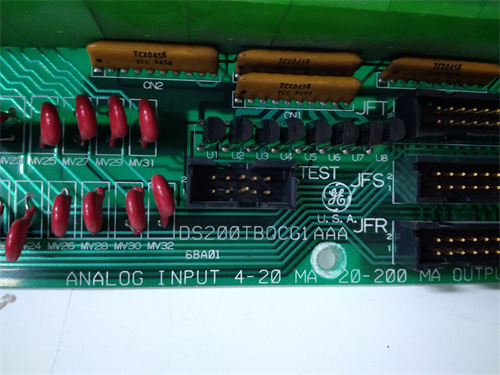

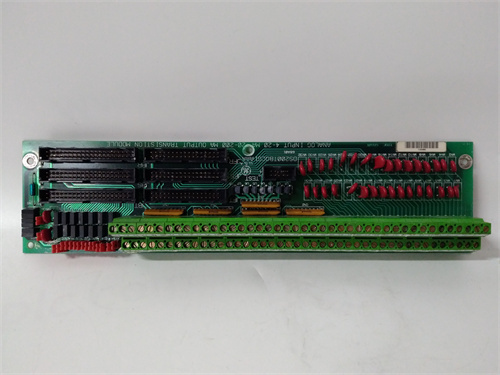

- Signal Types Supported: Power (24V DC/120V AC), analog (4-20mA, 0-10V, thermocouple/RTD), discrete (dry/wet contacts, relay outputs)

- Terminal Block Count: 48 positions (24 power/analog, 24 discrete)

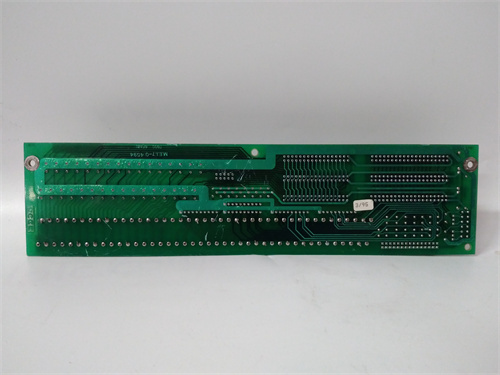

- Connector Type: MIL-DTL-38999 rugged circular connectors (for backplane connection) + screw-terminal blocks (field device connection)

- Wire Gauge Compatibility: 22–10 AWG (power/analog), 24–12 AWG (discrete)

- Current Rating: 15A per power terminal, 5A per analog terminal, 10A per discrete terminal

- Voltage Rating: 600V AC/DC (power), 300V AC/DC (analog/discrete)

2.2 Electrical & Protection Features

- Surge Protection: ±2kV ESD (IEC 61000-4-2) for analog/discrete channels; ±4kV surge (IEC 61000-4-5) for power terminals

- Short-Circuit Protection: Fused power terminals (replaceable 15A fuses)

- Isolation: 2500V AC between power and signal terminals; 1500V AC between analog and discrete terminals

- LED Indicators: Power presence (green), fuse status (red), surge fault (amber)

2.3 Environmental & Mechanical Parameters

- Operating Temperature: -40°C to +70°C (extended industrial range)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: 5-500Hz, 5g (IEC 60068-2-6, turbine environment compliant)

- Shock Resistance: 50g (11ms half-sine wave, IEC 60068-2-27)

- Form Factor: Rack-mount (19” compatible) / backplane-mounted, 200mm × 150mm × 40mm (fits Mark V/VI controller cabinets)

- Weight: 1.2kg

2.4 Certifications & Compliance

- Industry Certifications: CE, UL/cUL 508, ATEX Zone 2, IECEx

- Turbine Standards: API 612 (steam turbines), API 670 (machinery protection)

- EMI/EMC Compliance: EN 55032 (Class A), EN 61000-6-2 (industrial immunity)

3. Advantages & Features

- High-Density Connection Consolidation: GE DS200TBCBG1A integrates 48 power, analog, and discrete terminals into a single board, reducing the number of wiring points in turbine control cabinets by 50% and minimizing the risk of loose connections or short circuits.

- Rugged Vibration-Resistant Design: MIL-DTL-38999 backplane connectors and screw-locked terminal blocks ensure GE DS200TBCBG1A maintains secure connections even under extreme turbine-induced vibration, eliminating signal dropout or power loss in high-vibration environments (e.g., compressor stations).

- Integrated Protection Mechanisms: Fused power terminals and ±4kV surge protection shield GE DS200TBCBG1A and connected turbine control modules from electrical faults and transients, while LED indicators enable quick identification of fuse failures or surge events.

- Native GE Controller Compatibility: GE DS200TBCBG1A is pre-engineered for Mark V/VI turbine control backplanes, with plug-and-play installation that eliminates custom wiring adapters and reduces commissioning time by up to 40%.

- Turbine-Grade Durability: -40°C to +70°C operating temperature range and rugged construction allow GE DS200TBCBG1A to perform reliably in harsh conditions—from arctic steam turbine facilities to desert pipeline compressor stations.

4. Application Fields & Cases

4.1 Application Fields

- Combined-Cycle Power Plants: Gas/steam turbine controller wiring consolidation (fuel system, temperature sensors, safety interlocks)

- Fossil Fuel Power Plants: Steam turbine control cabinet terminal connection (lubrication pumps, pressure switches, governor actuators)

- Pipeline Compressors: Turbine controller wiring to anti-surge valves, emergency shutdown relays, and remote I/O modules

- Industrial Turbines: Compressor/pump driver turbine power/signal distribution (cooling fans, vibration sensors, starter motors)

4.2 Typical Cases

- Gas Turbine Control Cabinet Wiring (Europe): A German utility deployed GE DS200TBCBG1A in 25 combined-cycle power plant turbine control cabinets, replacing 3 separate terminal blocks with a single assembly. This reduced wiring errors by 70% during installation and cut maintenance time by 50% for connection troubleshooting.

- Steam Turbine Vibration-Resistant Connection (USA): A U.S. coal-fired power plant used GE DS200TBCBG1A in Mark V steam turbine controllers, leveraging its rugged connectors to maintain secure connections under high turbine vibration. The board eliminated 90% of signal dropout issues caused by loose wiring in previous systems.

- Pipeline Compressor Surge Protection (Middle East): A Saudi Arabian natural gas pipeline operator integrated GE DS200TBCBG1A into compressor turbine control systems, using its ±4kV surge protection to safeguard against lightning-induced transients. The board prevented 3 unplanned shutdowns in 2 years due to electrical surges.

5. Competitive Comparison

| Parameter | GE DS200TBCBG1A | Competitor A (Turbine Terminal Board) | Competitor B (Generic Terminal Block) |

|---|---|---|---|

| Terminal Count | 48 (Power/Analog/Discrete) | 32 (Mixed) | 24 (Discrete Only) |

| Vibration Resistance | 5g | 2g | 1g |

| Surge Protection | ±4kV (Power) / ±2kV (Signal) | ±2kV (All) | None |

| Turbine Compatibility | Mark V/VI | Mark VI Only | None |

| Connector Type | MIL-DTL-38999 + Screw-Terminal | Screw-Terminal Only | Spring-Terminal Only |

6. Selection Suggestions & Precautions

6.1 Selection Suggestions

- High-Density Turbine Control Cabinets: Choose GE DS200TBCBG1A for turbine systems requiring consolidation of power, analog, and discrete connections (e.g., combined-cycle power plants with complex control wiring).

- High-Vibration Environments: Opt for GE DS200TBCBG1A for pipeline compressors or industrial turbines with significant vibration, leveraging its rugged connectors to avoid loose connections.

- Mark V/VI Turbine Control Systems: Select GE DS200TBCBG1A to ensure seamless compatibility with GE’s flagship turbine controllers, eliminating integration issues and reducing installation time.

6.2 Precautions

- Installation Guidelines:

- Install GE DS200TBCBG1A only in compatible Mark V/VI controller backplanes; torque MIL-DTL-38999 connectors to GE-recommended specifications (20 N·m) to ensure vibration resistance.

- Route power and signal wires separately (per GE wiring guidelines) to minimize EMI interference—avoid running high-current power wires alongside low-voltage analog signals.

- Configuration Notes:

- Replace fuses only with GE-approved 15A components (do not bypass fuses or use higher-rated fuses) to maintain short-circuit protection.

- Label terminal blocks clearly during installation (per GE documentation) to simplify troubleshooting and maintenance.

- Troubleshooting:

- For power loss to a terminal: Check fuse status (red LED) and replace blown fuses; inspect wiring for short circuits or loose connections.

- For analog signal distortion: Verify isolation between power and signal terminals (use a multimeter to check for cross-talk) and relocate power wires if EMI is suspected.

- Maintenance:

- Tighten terminal block screws quarterly (vibration can cause loosening) to GE-recommended torque (0.5 N·m for signal terminals, 1.0 N·m for power terminals).

- Inspect surge protection diodes every 2 years (per GE recommendations) and replace the board if surge fault LEDs are continuously illuminated.

PTQ-PDPMV1 DCS

PTQ-PDPS PLC DCS

RLX2-IHNF-A PLC

RLX2-IHW-A

RLX2-IFH24E-A PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922 Wechat:+86 15343416922

Wechat:+86 15343416922