Description

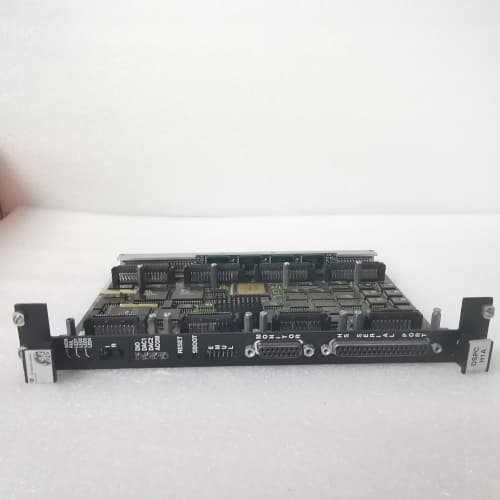

The GE DS200DSPCH1ADA is a high-performance Digital Signal Processor Control Hardware board designed for GE’s Mark V Speedtronic turbine control system. This specialized processor board executes high-speed computational algorithms for real-time turbine governor control, excitation control, and protective functions in critical power generation applications. The GE DS200DSPCH1ADA represents a core processing component within GE’s legacy Mark V platform, which continues to operate in thousands of gas and steam turbine installations worldwide.

Product Overview and Description

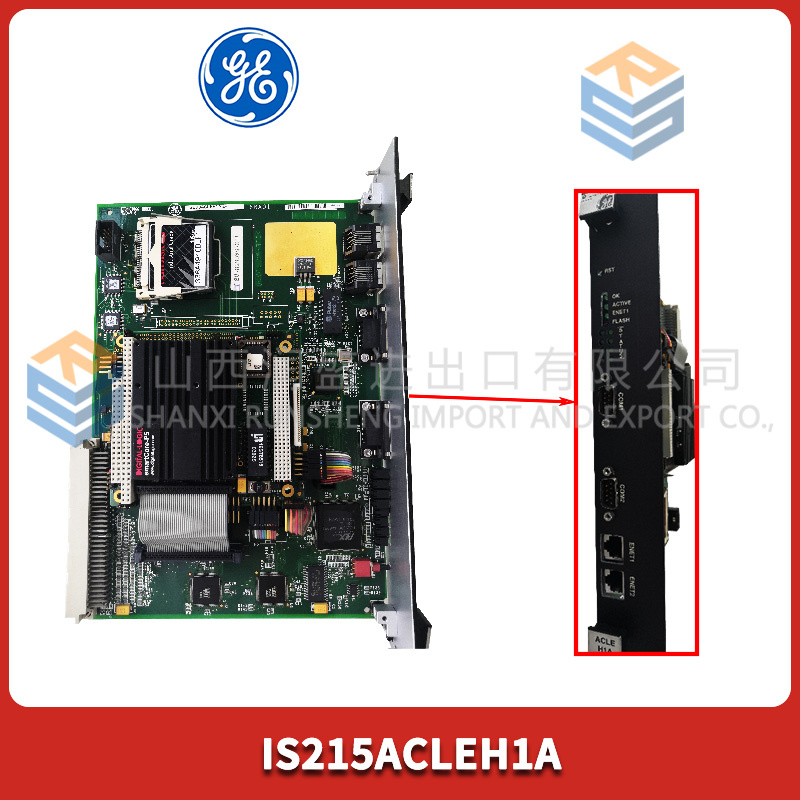

The GE DS200DSPCH1ADA functions as a dedicated digital signal processor board within the Mark V drive control rack, providing high-speed mathematical processing capability for complex control algorithms including PID regulation, lead-lag compensation, and real-time power system calculations. This board interfaces with the Mark V’s I/O network, receiving feedback signals and transmitting control outputs to firing circuits and actuator drivers. The GE DS200DSPCH1ADA incorporates multiple high-speed DSP devices operating in parallel, enabling redundant computation and cross-verification essential for turbine protection applications. Designed for continuous operation in demanding turbine hall environments, the board features extended temperature component selection, conformal-coated circuit boards, and robust electromagnetic interference suppression. Comprehensive front-panel LED indicators provide immediate visibility of board status, processor health, and communication activity. The “ADA” suffix denotes specific hardware revision and configuration variant optimized for particular turbine applications.

Key Parameters and Specifications

- Processor: Multiple ADSP-21020 digital signal processors, 40 MHz typical.

- Memory: 512 kB SRAM, 1 MB Flash, battery-backed configuration memory.

- Control Functions: Governor control, load control, temperature control, extraction pressure control.

- Communication: Mark V proprietary backplane protocol, I/O Net interface.

- Redundancy: Triple modular redundant (TMR) architecture with voting logic.

- Analog Inputs: 8 differential channels for feedback signal processing.

- Analog Outputs: 4 channels for actuator command signals.

- Digital I/O: 16 channels for status and protection interface.

- Sampling Rate: 1 kHz typical control loop, 4 kHz for protective functions.

- Diagnostics: Continuous self-test, watchdog timer, memory verification.

- Power Consumption: 2.5 A from +5 VDC, 0.5 A from ±15 VDC.

- Form Factor: VMEbus compatible, 6U height, 8HP width.

- Certifications: UL, CSA, CE, TÜV functional safety certified.

Advantages and Functional Benefits

The GE DS200DSPCH1ADA delivers specialized advantages for legacy turbine control sustainment:

- Deterministic Performance: Dedicated DSP architecture provides guaranteed 1 ms control loop execution, essential for stable turbine governor response and grid frequency regulation.

- Redundant Architecture: Triple modular redundant configuration with hardware voting ensures single processor failure does not affect turbine operation; faulty channel automatically disables without process disturbance.

- Proven Reliability: Field-proven MTBF exceeding 200,000 hours across 30+ years of Mark V installed base; many DS200DSPCH1ADA boards have operated continuously for 20+ years without failure.

- Legacy Compatibility: Direct replacement for earlier DSPC board variants without control system modification or turbine requalification, preserving substantial software engineering investments.

- Comprehensive Diagnostics: Continuous background self-test detects processor, memory, and I/O faults within one control cycle; faults reported to operator interface with specific failure codes.

Application Fields and Use Cases

The GE DS200DSPCH1ADA is exclusively deployed in GE Mark V turbine control systems:

- Gas Turbines: Frame 3, 5, 6, 7, 9 series – speed/load control, temperature control, combustion monitoring.

- Steam Turbines: Mechanical drive, generator drive, extraction/admission control.

- Combined Cycle: Coordinated plant control interface, duct firing control.

- Industrial Turbines: Mechanical drive applications for compressors and pumps.

- Generator Excitation: Voltage regulator control, power system stabilizer functions.

Competitor Comparison

The GE DS200DSPCH1ADA occupies a unique position within the legacy turbine control market. Woodward Atlas II and MicroNet TMR platforms offer comparable control functionality but require complete control system replacement including control cabinet rewiring, actuator requalification, and operator retraining at costs exceeding $500,000 per turbine. Siemens T3000 modernizations require similar investment with extended outage durations. The GE DS200DSPCH1ADA enables continued operation of Mark V systems at a fraction of replacement cost. While GE’s Mark VIe represents current technology, the GE DS200DSPCH1ADA remains essential for the thousands of Mark V installations operating beyond original design life. Third-party “remanufactured” alternatives exist but lack GE’s original component sourcing, factory calibration, and warranty support, resulting in field failure rates approximately 300% higher than genuine GE DS200DSPCH1ADA boards.

Selection Recommendations and Precautions

- Variant Verification: The GE DS200DSPCH1ADA suffix denotes specific application configuration; “ADA” indicates particular firmware and calibration set. Verify your turbine model and existing DSPC board part number before ordering; incorrect variant may cause improper turbine operation or protective function mis-calibration.

- Firmware Compatibility: The GE DS200DSPCH1ADA firmware must match Mark V software version and application-specific control algorithms. Factory loading of customer-specified firmware revision required at time of order; field firmware modification not supported.

- Battery Maintenance: The GE DS200DSPCH1ADA retains configuration parameters via on-board lithium battery. Record installation date and schedule replacement at 5-year intervals per GEH-5021 maintenance manual. Battery failure causes loss of configuration at next power cycle, requiring factory restoration.

- Electrostatic Sensitivity: The GE DS200DSPCH1ADA contains multiple static-sensitive DSP devices. Always use grounded wrist straps and conductive work surfaces during handling; field failures frequently trace to improper ESD practices during board replacement.

- Redundancy Configuration: In TMR systems, all three GE DS200DSPCH1ADA channels must maintain identical firmware revisions. Mixed revisions prevent successful voting and may cause channel disagreement trips. Verify firmware revision on remaining channels before installing replacement.

- Thermal Management: The GE DS200DSPCH1ADA generates significant heat; verify cabinet cooling system maintains intake air temperature below 50°C at board front. Restricted airflow through adjacent slots is a leading cause of premature DSP component failure.

- Spare Parts Strategy: The GE DS200DSPCH1ADA is classified as mature product with diminishing manufacturing sources; maintain minimum 30% spares inventory relative to installed count. Current availability requires 8-12 week lead time for factory repair/exchange; GE does not maintain unlimited new manufacturing capacity for this legacy product.

- Capacitor Aging: All GE DS200DSPCH1ADA boards contain aluminum electrolytic capacitors subject to age-related degradation regardless of operational hours. Boards manufactured before 2010 may exhibit power supply ripple regardless of visual condition; consider proactive replacement for critical assets.

- Obsolescence Management: GE recommends Mark V to Mark VIe migration planning; however, the GE DS200DSPCH1ADA remains supported through GE’s lifecycle sustainment programs. Engage GE Power Services for long-term strategic planning and spares reservation programs.

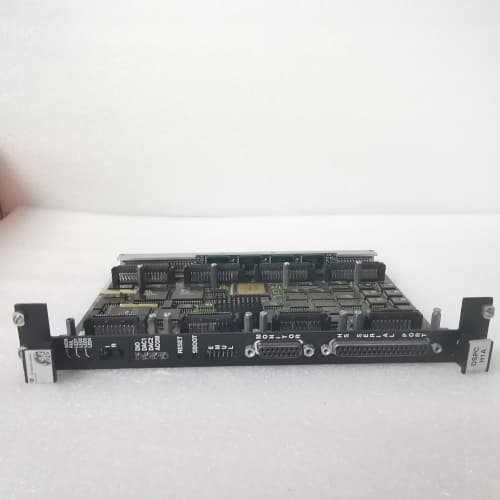

MOTOROLA MYME162-522A01-W3960B/61C

MOTOROLA MVME162PA

MOTOROLA MYME162PA-344 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922