Description

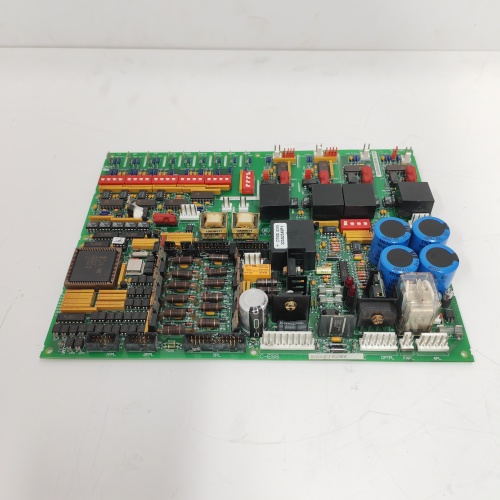

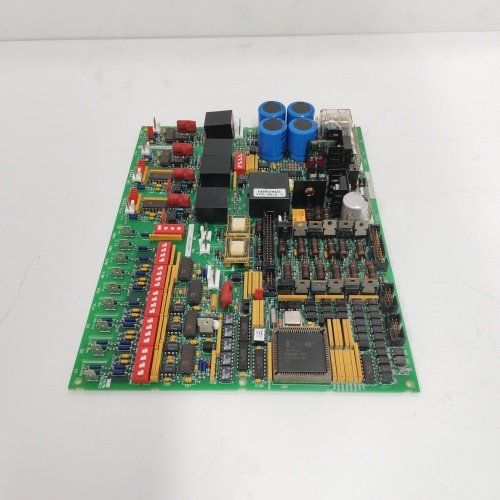

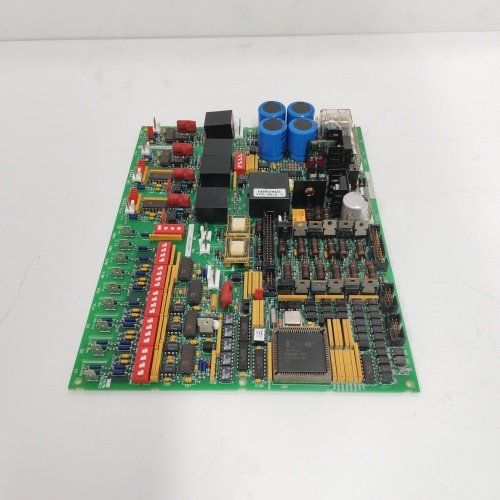

GE DS200DCFBG2BNC & DS200DCFBG1BNC – Product Overview

Product Description

The GE DS200DCFBG1BNC and its variant, the GE DS200DCFBG2BNC, are critical fiber-optic communication interface boards designed for the GE Mark V and Mark VI series gas/steam turbine control systems., are responsible for managing the high-speed, noise-immune communication between the turbine control modules within the TMR (Triple Modular Redundant) architecture. Implementing either the GE DS200DCFBG1BNC or the GE DS200DCFBG2BNC is essential for ensuring synchronized operation and data exchange between the redundant controller legs. The reliability of this fiber-optic communication link is paramount for the safe, fast, and coordinated control of critical turbomachinery.

Product Parameters

-

Part Numbers: DS200DCFBG1BNC (Legacy/Base Version), DS200DCFBG2BNC (Enhanced/Revised Version)

-

Product Family: GE Mark V / Mark VI Speedtronic Turbine Control

-

Board Type: Fiber-Optic Communication Board (also referred to as a Bridge or IONET board)

-

Primary Function: Facilitates the exchange of control and protection data between the three independent controller processors (R, S, T legs) in a TMR system via a proprietary fiber-optic network (IONET).

-

Communication Protocol: Proprietary GE high-speed deterministic protocol over fiber.

-

Key Difference: The suffix “G2” in DS200DCFBG2BNC typically indicates a later hardware revision or an enhancement over the “G1” version, potentially with improved components, firmware, or compatibility for Mark VI systems. They are often not directly interchangeable without system reconfiguration.

-

Connectors: ST-type fiber-optic connectors.

Advantages and Features

-

High Noise Immunity: Fiber-optic communication is completely immune to electromagnetic interference (EMI), radio frequency interference (RFI), and ground loop problems, which is critical in the electrically noisy environment of a power plant.

-

High-Speed & Deterministic: Enables the ultra-fast, synchronized data exchange required for the TMR system to perform vote-and-act operations, ensuring both protection and control speed.

-

System Integrity: Forms the backbone of the triple-redundant control network. A failure in this communication can lead to a turbine trip or degraded control mode.

-

Diagnostic Capabilities: The system software provides diagnostics for the fiber-optic link integrity, helping to isolate communication faults between controller racks.

-

Proven Design: A core component of the widely deployed Speedtronic control systems, known for their reliability in critical power generation applications.

Application Cases in Application Fields

These modules are exclusively used in heavy-duty turbomachinery control:

-

Power Generation (Gas & Steam Turbines): The primary application. The DS200DCFBG1BNC or DS200DCFBG2BNC is installed in each controller rack (R, S, T) of a GE Frame 5, 6, 7, 9 or similar gas turbine, or in steam turbine controls, to maintain TMR synchronization.

-

Mechanical Drive Turbines: Used in applications where large turbines drive compressors in oil & gas pipelines or refineries.

-

Marine Propulsion: In naval or large commercial vessels powered by gas turbines.

Comparisons with Competing Products

-

vs. Siemens / Woodward Turbine Control Systems: Competing turbine control systems use their own proprietary hardware and communication schemes (e.g., Siemens uses Teleperm or T3000 with Ethernet-based redundancy). The GE DS200DCFBGxBNC modules are unique to the GE Speedtronic ecosystem and its specific TMR architecture.

-

vs. Standard PLC Fiber Modules: Standard industrial fiber modules for Ethernet or PROFIBUS are for general data transfer. The DS200DCFBG1BNC/2BNC is purpose-built for a deterministic, safety-critical, hard-real-time control network with millisecond-level synchronization requirements that general networks cannot guarantee.

-

vs. Older GE Speedtronic Comm Boards (e.g., DS200DCFBG1AAA): The “BNC” suffix indicates a specific revision or connector type. The “G2” version (DS200DCFBG2BNC) typically supersedes the “G1” (DS200DCFBG1BNC), offering better long-term availability and potentially enhanced compatibility with Mark VI upgrades.

Selection Suggestions and Precautions

-

Selection Suggestion: Selection is dictated by the specific turbine unit’s original Bill of Material (BOM) and control system upgrade status.

-

For like-for-like replacement in a Mark V or early Mark VI system, you must identify the exact board currently installed.

-

The GE DS200DCFBG2BNC is generally the preferred choice for spares if it is a compatible successor, as it may have improved reliability.

-

Always consult the turbine’s control system manual and GE documentation or a qualified turbine control engineer before ordering.

-

-

Precautions:

-

Not Interchangeable by Default: Do not assume DS200DCFBG1BNC and DS200DCFBG2BNC are directly swappable. A firmware mismatch or hardware difference can cause a communication fault and turbine trip.

-

Handle with Extreme Care: Fiber-optic connectors and ports are sensitive to dust, scratches, and physical damage. Use protective caps when unplugged and clean connectors properly with approved tools before installation.

-

Static Sensitive: These are static-sensitive electronic components. Use proper ESD (electrostatic discharge) handling procedures.

-

Configuration Required: Simply installing a new board may not be sufficient. The module may require specific firmware and configuration downloads from the turbine’s toolset software (ToolboxST) to function correctly within its designated control leg.

-

0-57C406-E I/O

0-57C407-4H PLC

0-57C408-B DCS

0-57C411-2 PLC

0-60002-6 PLC

0-60007-2

0-60010-E PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922