Description

Product Description

The GE CP238TA is a high-performance power supply module engineered specifically for GE Fanuc’s Series 90-30 PLC platform, providing reliable DC power conversion for CPU, I/O, and specialty modules in industrial control applications. This compact, DIN-rail mountable power supply accepts wide-range AC input and delivers isolated 24 V DC output for backplane power distribution and field device energization. The GE CP238TA represents the culmination of GE’s field-proven Series 90-30 power supply technology, designed for continuous duty in manufacturing, water/wastewater, material handling, and infrastructure control applications. Engineered for harsh industrial environments, this module features extensive transient protection, overcurrent limiting, and thermal shutdown protection. The GE CP238TA mounts directly on Series 90-30 racks and provides power status indication via front panel LED, enabling rapid troubleshooting without external metering equipment.

Product Parameters

- Model: GE CP238TA

- Product Type: Power Supply Module, Series 90-30 PLC

- Input Voltage: 85–264 V AC, 47–63 Hz (universal input)

- Input Current: 1.5 A RMS maximum at 115 V AC, 0.8 A RMS at 230 V AC

- Output Voltage: 24 V DC nominal (22–26 V DC)

- Output Current: 8 A continuous for backplane, 1 A for field power

- Output Power: 192 W maximum

- Output Protection: Overcurrent limiting (105–125%), overvoltage protection (30 V DC typical), thermal shutdown (90°C)

- Hold-up Time: 20 ms minimum at full load

- Efficiency: > 80% at full load

- Ripple/Noise: < 50 mV peak-to-peak

- Isolation: 1500 V AC input-to-output, 1500 V AC input-to-ground

- Indicators: Power OK LED (green), overload LED (red)

- Mounting: Direct mount to Series 90-30 rack, also supports DIN rail mounting with adapter

- Operating Temperature: 0°C to 60°C

- Cooling: Convection cooled, no internal fan

- Certifications: CE, UL, CSA, RoHS compliant, Class I Div 2 (with appropriate enclosure)

Advantages and Features

The GE CP238TA delivers exceptional reliability through its robust linear-derived switching topology, combining the efficiency of switch-mode technology with the noise performance characteristics approaching linear power supplies. Unlike universal power supplies requiring external circuit breakers and filtering, the GE CP238TA provides fully integrated input protection including fuse, EMI filtering, and transient suppression, significantly reducing panel component count and wiring complexity. The module’s dual-output architecture provides separate 8 A backplane power for PLC modules and 1 A isolated field power for sensors and actuators, eliminating separate power supplies for basic control applications. Comprehensive protection features including foldback current limiting and thermal shutdown prevent catastrophic failure under output short circuit conditions, with automatic recovery upon fault clearance. The GE CP238TA‘s wide-range universal input accepts any global AC mains voltage without jumper configuration, simplifying international machine builds and field retrofits. Front panel diagnostic LEDs provide immediate visual indication of power status and overload conditions, enabling rapid troubleshooting without specialized test equipment. The module’s convection-cooled design eliminates fan failures common in forced-air cooled power supplies, significantly improving mean time between failures in dusty industrial environments. The GE CP238TA supports hot-swap replacement in redundant power supply configurations when paired with appropriate Series 90-30 redundant power supply racks.

Application Cases in Application Fields

- Automotive Assembly Lines: Deployed on body shop welding control systems, multiple GE CP238TA power supplies provide reliable 24 V DC power to Series 90-30 racks controlling robotic weld cells, with the module’s 20 ms hold-up time maintaining control during spot welder-induced voltage sags.

- Water Treatment Facilities: Installed in municipal wastewater treatment plants, the GE CP238TA powers Series 90-30 PLCs controlling aeration blowers and chemical feed systems, its convection-cooled design ensuring reliable operation in non-air-conditioned pump stations.

- Food & Beverage Packaging: Utilized on high-speed bottling lines, the GE CP238TA provides isolated field power for proximity sensors and solenoid valves, its low-noise output eliminating false triggering of sensitive capacitive proximity sensors.

- Material Handling Systems: Applied in automated warehouse conveyor control, multiple GE CP238TA units power distributed Series 90-30 racks throughout sortation systems, eliminating centralized power distribution and reducing 24 V DC voltage drop issues.

- Infrastructure Tunnel Ventilation: Implemented in road tunnel ventilation control systems, the GE CP238TA‘s wide-range input accommodates backup generator frequency variations during mains power loss, maintaining PLC operation throughout emergency sequences.

Comparison with Competing Products

| Feature | GE CP238TA | Allen-Bradley 1606-XLP | Siemens PS 307 | AutomationDirect PWR-2424 |

|---|---|---|---|---|

| Output Voltage | 24 V DC | 24 V DC | 24 V DC | 24 V DC |

| Output Current | 8 A (backplane) + 1 A (field) | 8 A (single output) | 10 A (single output) | 10 A (single output) |

| Form Factor | Series 90-30 rack mount | DIN rail mount | S7-300 rack mount | DIN rail mount |

| Input Voltage | 85–264 V AC universal | 85–264 V AC universal | 120/230 V AC selectable | 85–264 V AC universal |

| Hold-up Time | 20 ms | 20 ms | 20 ms | 15 ms |

| Field Power Output | Yes (1 A isolated) | No | No | No |

| Hot-Swap Capable | Yes (with redundant rack) | No | No | No |

| System Integration | Series 90-30 native | Universal | S7-300 native | Universal |

| Typical Cost Position | Mid | Mid | Mid-High | Low |

The GE CP238TA offers unique value through its integrated field power output, a feature absent from competing PLC power supplies including Allen-Bradley 1606-XLP and Siemens PS 307. This single-unit solution eliminates separate sensor power supplies for applications with modest field I/O requirements, reducing both component cost and panel space. While universal power supplies offer lower acquisition cost, the GE CP238TA‘s native integration with Series 90-30 backplanes eliminates interconnecting wiring and associated failure points. The module’s hot-swap capability in redundant configurations provides availability advantages unavailable from DIN rail mounted universal power supplies. For facilities standardized on GE Series 90-30 platforms, the GE CP238TA remains the optimal power supply solution for new installations and legacy system maintenance.

Selection Suggestions and Precautions

- System Compatibility Verification: Confirm that your Series 90-30 rack model supports the GE CP238TA; all 5-slot, 10-slot, and 14-slot racks are compatible, but early 90-30 systems with legacy power supply mounting may require rack adapter hardware.

- Load Calculation Requirements: Before specifying the GE CP238TA, calculate total backplane current requirements of all installed CPU, I/O, and specialty modules; do not exceed 8 A total backplane current including 5 V, ±12 V, and 24 V backplane loads.

- Field Power Utilization: The GE CP238TA provides 1 A of isolated 24 V DC field power; this output is suitable for energizing proximity sensors, limit switches, and small relays; for larger field device populations, utilize external power supplies to avoid module overload.

- Input Protection Coordination: Although the GE CP238TA includes internal fusing, install external branch circuit protection (10 A maximum) per electrical code requirements; coordinate trip characteristics to avoid nuisance tripping during module inrush current.

- Redundancy Configuration: For critical processes requiring power supply redundancy, configure dual GE CP238TA modules with Series 90-30 redundant power supply rack (IC693CHS398); verify that total system load does not exceed single module capacity to maintain full redundancy benefit.

- Environmental Installation: Mount the GE CP238TA in vertical orientation with adequate ventilation clearance (minimum 50 mm above/below); do not install directly above heat-generating devices such as solid-state relays or heating elements.

- Spare Parts Strategy: Given the GE CP238TA‘s extensive installed base and GE’s transition to PACSystems platforms, maintain configured spare modules representing 5-10% of installed population; typical lead times range 4-6 weeks.

- Obsolescence Awareness: Series 90-30 platform remains supported but GE has designated this technology as “mature”; facilities planning 10+ year operating horizons should evaluate PACSystems RX3i migration paths while maintaining adequate GE CP238TA spares for interim reliability.

- Input Voltage Verification: Although the GE CP238TA accepts 85–264 V AC, verify actual site voltage falls within specified range; continuous operation at voltage extremes reduces module service life and may trigger premature overload indication.

- Output Derating: The GE CP238TA‘s 8 A output rating is specified at 60°C; at elevated ambient temperatures, derate output current linearly to 6 A at 70°C; consult derating curve in product manual for specific application conditions.

- Grounding Requirements: The GE CP238TA requires protective earth ground connection via rack mounting or dedicated ground terminal; inadequate grounding compromises both operator safety and electromagnetic compatibility performance.

- Battery Backup Considerations: The GE CP238TA‘s 20 ms hold-up time maintains PLC operation through brief power interruptions; for extended outages, integrate external UPS system sized for total control system load including the GE CP238TA.

- Pre-Commissioning Verification: Before applying power to the GE CP238TA, verify that all field wiring terminations are tight and free of shorts; measure output impedance to ground before initial startup to prevent damage from undetected wiring errors.

- Periodic Maintenance: Inspect the GE CP238TA ventilation openings quarterly in dusty environments; accumulated debris restricts airflow, causing thermal shutdown at reduced output current levels; clean with dry compressed air at 20 psi maximum.

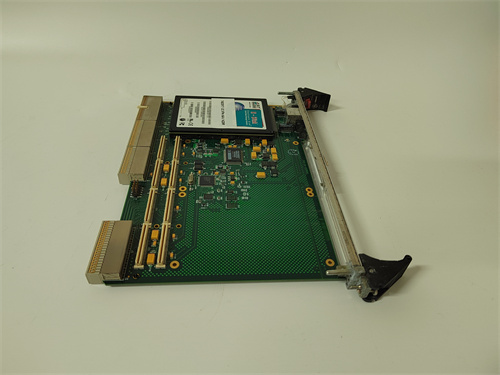

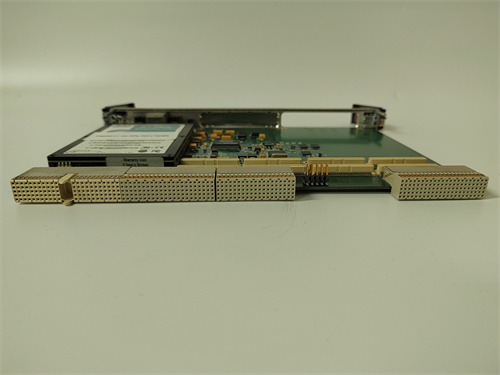

MOTOROLA MVME162–210

MOTOROLA MVME162-212 PLC

MOTOROLA MVME162-220

MOTOROLA MVME162–512A

MOTOROLA MYME162-522h

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922