Description

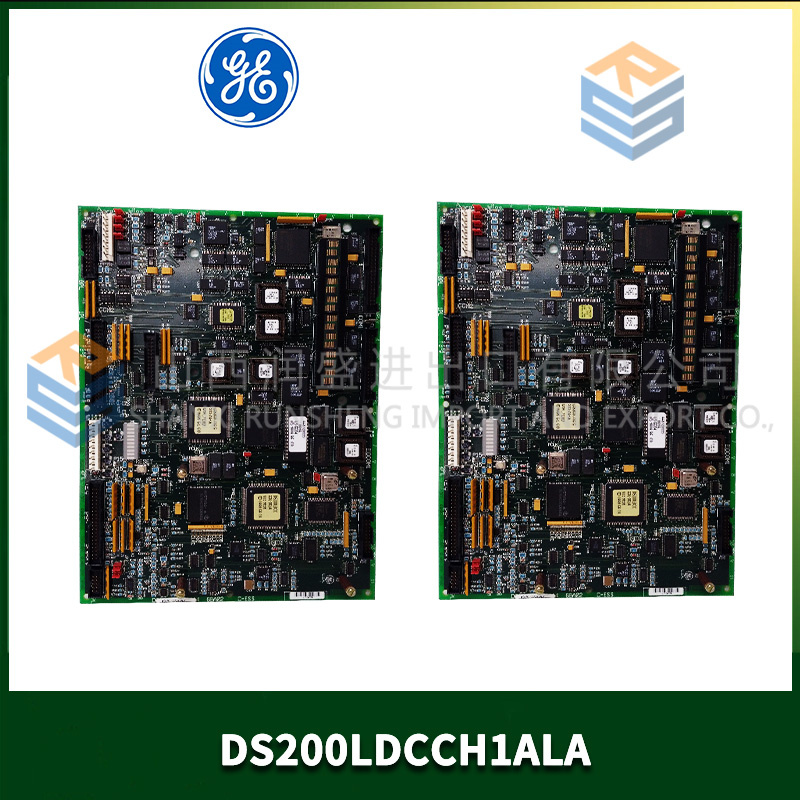

Product Overview and Description

The GE 531X304IBDARG1 is a specialized I/O and communication processor board designed for the GE Mark VIe turbine control system. This board functions as a critical component within the Mark VIe’s distributed I/O network, serving as an intelligent terminal board that handles both local analog/digital I/O signals and network communication. The GE 531X304IBDARG1 acts as an interface between the field wiring from sensors and actuators and the high-speed control network, facilitating data acquisition and command distribution for gas or steam turbine control and protection.

Product Parameters

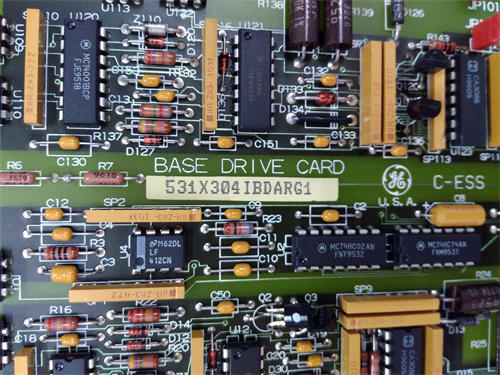

- Board Type: I/O Processor & Communication Board (Terminal Board).

- Compatibility: GE Mark VIe Turbine Control System.

- Primary Functions:

- I/O Processing: Manages a local cluster of I/O modules (e.g., analog input, digital input, relay output cards) installed directly onto it via a dedicated backplane connector.

- Network Communication: Integrates a network interface (typically Ethernet) to communicate with the Mark VIe controller (URM, URH) and other terminal boards over the high-speed ControlNet or Ethernet I/O network.

- Network Protocol: Uses the GE TMR (Triple Modular Redundant) or Simplex high-speed peer-to-peer network protocol for deterministic data exchange.

- Local I/O Support: Designed to host specific types and quantities of Mark VIe series I/O packs (e.g., IS200/IS215 series modules).

- Configuration: Programmed and configured using GE’s ToolboxST software. Its firmware defines its role and the mapping of I/O points.

- Power Supply: Receives power from the system’s DC power supply through the rack backplane.

- Environmental Rating: Designed for industrial control cabinet environments associated with turbine installations.

Advantages and Key Features

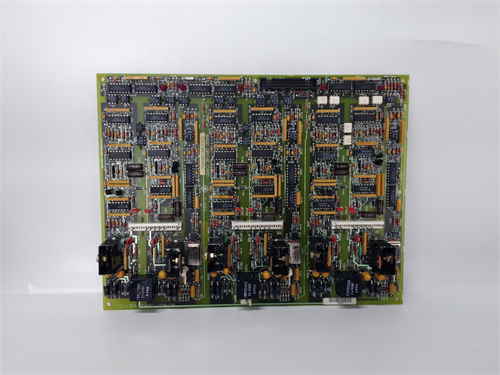

- Distributed Intelligence: The GE 531X304IBDARG1 decentralizes processing, reducing the load on the main controller and improving system response time by handling I/O scanning and preprocessing locally.

- Deterministic Network Performance: It operates on GE’s high-speed, deterministic control network, ensuring precise and timely data transfer between the controller and I/O points, which is critical for fast-acting turbine protection loops.

- Modular and Scalable Design: This terminal board allows for flexible system configuration. I/O capacity can be expanded by adding modules to the board, and multiple GE 531X304IBDARG1 boards can be added to the network to distribute I/O geographically around the turbine.

- High Reliability and Diagnostics: Built with industrial-grade components and featuring comprehensive self-diagnostics, it monitors its health, network status, and the status of its attached I/O modules, reporting faults to the central controller for immediate action.

- Seamless Mark VIe Integration: As a native component, the GE 531X304IBDARG1 is fully recognized and managed within the ToolboxST engineering environment, simplifying configuration, commissioning, and troubleshooting of the entire turbine control system.

Application Cases in Various Fields

- Gas Turbine Power Generation: Located in a remote cabinet near the turbine deck to interface with fuel valve positioners, flame detectors, and vibration probes, with the GE 531X304IBDARG1 processing signals and communicating data to the main Mark VIe controller in the control room.

- Steam Turbine Control: Installed near the turbine’s steam chest to handle inputs from temperature sensors (thermocouples) and outputs to governor servo valves, providing fast local control loops.

- Compressor Station Control: Used in turbine-driven compressor packages to manage anti-surge valve controls and process measurements, distributing I/O points close to the equipment.

- Combined Cycle Plant Balance of Plant: Controlling and monitoring auxiliary systems such as lube oil consoles or cooling water pumps, where distributed I/O managed by this board reduces long wiring runs.

Comparison with Competing Products

The GE 531X304IBDARG1 is a proprietary component within the GE Mark VIe ecosystem. Competing products would be distributed I/O processors from other turbine control OEMs like Siemens (ET 200SP for T3000) or Woodward (NetCon I/O nodes). Compared to a standard industrial Ethernet I/O block (e.g., from Beckhoff or Wago), the GE 531X304IBDARG1 is specifically engineered for the harsh environment, deterministic requirements, and safety-critical nature of turbine control. Its firmware and communication protocol are optimized for integration with GE’s protection and sequencing logic. Its primary advantage is guaranteed performance and support within a Mark VIe system, whereas a third-party I/O system would require complex and uncertified integration.

Selection Suggestions and Precautions

- Selection Advice:

- System Design Knowledge: This board must be selected as part of a complete Mark VIe system design. Its use, network address, and I/O module complement are defined in the original turbine control application software.

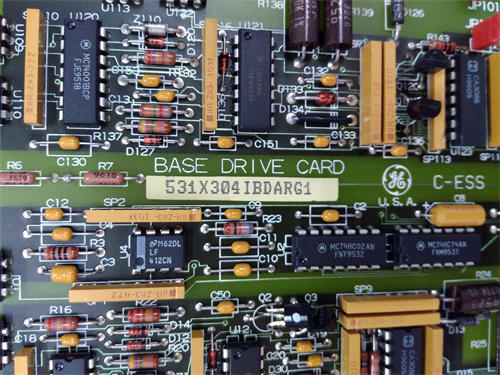

- Exact Replacement: When used as a spare, it is crucial to replace it with the exact same board model (GE 531X304IBDARG1) and firmware revision to ensure compatibility with the existing configuration.

- I/O Module Compatibility: Verify that the existing I/O modules attached to the failed board are compatible and that their configuration is backed up.

- Important Precautions:

- Critical System Component: This board is part of a safety-related control system. Any work must be performed under a formal safety procedure (lockout/tagout) by personnel trained on the Mark VIe system.

- Electrostatic Discharge (ESD): Handle as an ESD-sensitive component using proper grounding straps and anti-static packaging.

- Configuration is Vital: The board is not plug-and-play. The replacement GE 531X304IBDARG1 must have its configuration downloaded from the ToolboxST project or restored from a backup of the failed board. A blank or misconfigured board will not communicate properly.

- Network Address: Ensure the board’s hardware address (set via switches) matches the address defined in the control system configuration. An address conflict will cause a network fault.

- Firmware Synchronization: The board’s firmware version must be compatible with the system’s controller and ToolboxST software version. An upgrade may be required.

- Authorized Sources: Due to its critical function, source this board only from GE or certified refurbishers who can provide unit-specific testing documentation.

1C31197G01

EMERSON 1C31219G01

EMERSON 1C31222G01

1C31223G01 EMERSON

1C31224G01 EMERSON

1C31227G01 EMERSON

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922