Description

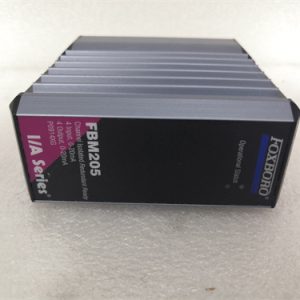

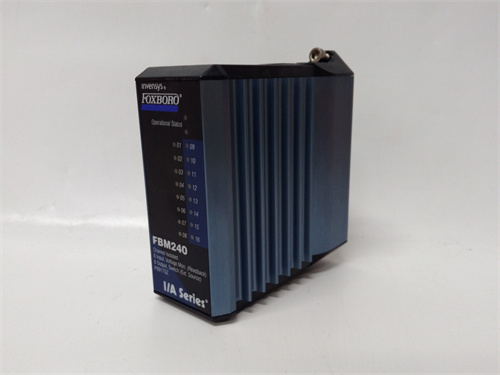

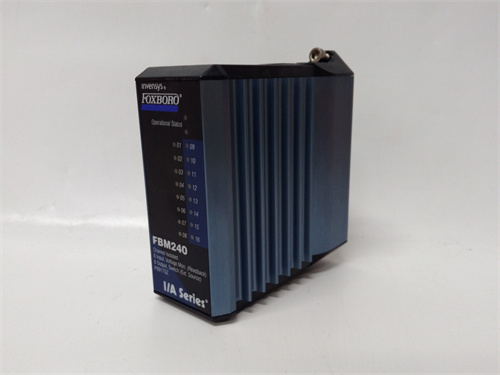

Product Analysis: FOXBORO FBM240

Introduction and Product Description

The FOXBORO FBM240 is a high-density analog output module integral to the Foxboro I/A Series Distributed Control System (DCS), a premier automation platform for process industries. This module functions as a critical command interface, converting digital control signals from the Series’ controllers into precise analog current outputs to field devices such as control valves, variable frequency drives (VFDs), and actuator positioners. The FOXBORO FBM240 is a key component of the Fieldbus Module (FBM) family, designed for rugged reliability and high performance in demanding environments. It enables the execution of final control element commands with the accuracy and stability required for tight regulatory control. As a cornerstone of many legacy and modernized I/A Series systems, the FOXBORO FBM240 remains a vital spare part for maintaining operational continuity.

Product Parameters

- Manufacturer: Foxboro (a part of Schneider Electric)

- System: Foxboro I/A Series DCS

- Module Type: Analog Output Fieldbus Module (FBM)

- Channels: 8 independent analog output channels.

- Output Signal: 4 to 20 mA DC, with optional HART communication capability per channel (model specific, e.g., FOXBORO FBM240 with HART).

- Load Capacity: Typically drives loads up to 750 ohms.

- Resolution: High resolution (e.g., 15-bit plus sign) for precise control signal generation.

- Isolation: Channel-to-channel and channel-to-system isolation for safety and noise immunity.

- Update Rate: Fast update times synchronized with the I/A Series control network.

- Redundancy: Supports module-level redundancy when paired with a redundant FBM in a designated pair.

Advantages and Features

- High-Density Output: The FOXBORO FBM240 consolidates eight control outputs in a single module slot, optimizing cabinet space and reducing system footprint compared to lower-density alternatives.

- Integrated HART Capability: Many versions of this module support the HART protocol, allowing for simultaneous analog output and digital communication for valve diagnostics, configuration, and device information without requiring separate hardware.

- High Reliability and Availability: Designed for continuous operation, the FOXBORO FBM240 supports hot-swap replacement and redundant configurations, minimizing downtime during maintenance or in the event of a module failure.

- Seamless I/A Series Integration: The module is automatically recognized and configured by the I/A Series control software, ensuring easy integration and comprehensive diagnostics within the native Foxboro environment.

- Robust Industrial Design: Built to withstand industrial environments with protection against electrical noise, vibration, and wide operating temperature ranges.

Application Cases in Key Fields

- Oil & Gas Refining: Critical for controlling final elements such as flow control valves on distillation columns, reactor feed lines, and fuel systems for fired heaters.

- Chemical & Petrochemical Plants: Used to manipulate reactor temperature control valves, product draw valves, and pump recirculation valves to maintain precise process conditions.

- Power Generation: Controls feedwater valves, steam turbine governor valves, and damper actuators in boiler control systems for efficient and stable plant operation.

- Pharmaceutical & Biotech: Provides precise analog commands to control valves in bioreactors, filtration systems, and clean-in-place (CIP) systems where accurate dosing and flow control are paramount.

Comparison with Competing Products

Compared to analog output modules from other DCS platforms like Honeywell’s C Series or Emerson’s DeltaV, the FOXBORO FBM240 offers comparable density and performance within its proprietary I/A Series ecosystem. Its integration of HART communication is a significant advantage over basic analog-only modules. Compared to standard PLC analog output cards (e.g., Allen-Bradley 1756-OF8), the FOXBORO FBM240 is typically part of a more tightly integrated system with better inherent diagnostics, redundancy options, and a control architecture optimized for complex process loops. For legacy I/A Series systems, it is the only form-fit-function replacement option.

Selection Suggestions and Precautions

- Selection:

- Verify Exact Model & Revision: Confirm the full part number, including any suffix (e.g., for HART, specific firmware revision). The FOXBORO FBM240 must match the failed module’s specifications.

- Check HART Requirement: Determine if your application requires HART communication on the analog outputs. Select the HART-capable version of the FOXBORO FBM240 if needed.

- Confirm Compatibility: Ensure compatibility with the host FBM carrier (e.g., FBM 201, 202) and the I/A Series nodebus.

- Precautions:

- Safety Procedures: Before replacement, follow plant safety protocols. Place associated control loops in manual or safe state. Isolate the field load if possible to prevent unexpected valve movement.

- Hot-Swap Procedure: If replacing in a redundant or hot-swappable configuration, strictly adhere to the documented Foxboro procedure for module removal and insertion to avoid bus disturbances.

- HART Configuration: If using a HART-capable FOXBORO FBM240, ensure the I/A Series software is configured to enable HART communication on the appropriate channels for your field devices.

- Field Wiring Check: Before powering the new module, verify field wiring for proper connection, isolation, and the absence of shorts to ground or between channels.

- Loop Verification: After installation, perform a full loop check for each channel. This includes verifying the output current at the controller and at the field device to ensure signal integrity and correct calibration.

Fanuc IC693CPU331K PLC

IS200TDBSH2A PLC

IS220SRTDH2A PLCCPU

IS200ECTBG2A PLC

IS420UCSBH1A

IS200VCRCH1B PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922