Description

Product Description

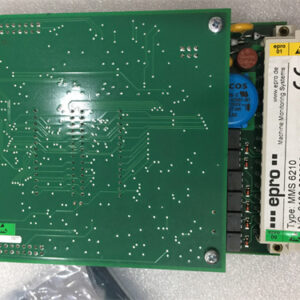

The EPRO PR9268/300-000 is a high-performance eddy current displacement sensor system specifically engineered for turbine supervisory instrumentation in power generation, oil and gas, and industrial rotating machinery applications. This advanced transducer forms the sensing element for non-contact measurement of shaft vibration, axial position, and eccentricity in steam turbines, gas turbines, compressors, and large rotating equipment. The EPRO PR9268/300-000 operates on the eddy current principle, generating a low-power radio frequency field that detects target displacement with micrometer resolution independent of non-conductive contaminants. Designed as direct form-fit-function replacement for legacy Bentley Nevada 3300 series sensors, the EPRO PR9268/300-000 interfaces seamlessly with EPRO’s MMS 6000 and CONCEPT monitoring systems as well as third-party vibration monitors. The sensor incorporates a rugged stainless steel housing with integral coaxial cable, engineered to withstand turbine hall vibration, elevated temperatures, and oil mist environments.

Product Parameters

- Model: EPRO PR9268/300-000

- Sensor Type: Eddy current displacement probe, non-contact

- Measurement Principle: Impedance change due to eddy current losses

- Linear Range: 2.0 mm nominal (0.25–2.25 mm gap)

- Sensitivity: 8.0 V/mm ± 5% at 25°C

- Frequency Response: 0 to 10 kHz (–3 dB)

- Target Material: Ferromagnetic or non-ferromagnetic conductive materials

- Temperature Stability: ±0.05% FS/°C typical

- Output Signal: -4 to -20 V DC (negative slope)

- Excitation: -24 V DC via PR9377 or compatible driver

- Probe Diameter: 8 mm sensing face

- Housing Material: AISI 316 stainless steel

- Cable Type: Integrated coaxial, 5 meters standard (custom lengths available)

- Connector: BNC or MS type, depending on driver compatibility

- Operating Temperature: -30°C to +120°C (probe), -30°C to +80°C (cable)

- Protection Rating: IP68 (probe), IP67 (connector)

- Certifications: CE, ATEX/IECEx Ex nA IIC T4 (Zone 2), CSA Class I Div 2, DNV/GL marine type approval

Advantages and Features

The EPRO PR9268/300-000 delivers exceptional measurement accuracy through its advanced coil design and proprietary temperature compensation circuitry, maintaining specified sensitivity across the entire operating temperature range without external linearization. Unlike optical or laser-based systems, the EPRO PR9268/300-000 is entirely immune to oil mist, steam, dust, and electromagnetic interference from adjacent power cables, making it ideally suited for turbine bearing applications. Its negative slope output characteristic (–4 to –20 V DC) provides inherent fail-safe behavior, with cable break or power loss conditions driving the monitoring system to alarm state. The EPRO PR9268/300-000 features full interchangeability without system recalibration when used with EPRO signal conditioners, significantly reducing maintenance downtime. The sensor’s sealed construction and welded titanium window provide exceptional resistance to hydrogen embrittlement and stress corrosion cracking in high-pressure steam environments. Integrated cable strain relief and flexible conduit adaptability ensure reliable operation under continuous vibration up to 50 g.

Application Cases in Application Fields

- Steam Turbine Radial Vibration: Deployed on LP turbine bearings in 800 MW coal-fired power stations, the EPRO PR9268/300-000 provides real-time shaft relative vibration measurement to API 670 standards, enabling predictive maintenance scheduling based on trend analysis.

- Gas Turbine Thrust Position: Installed on Frame 9FA gas turbines in combined cycle facilities, this sensor monitors axial shaft displacement with micrometer resolution, with the EPRO PR9268/300-000‘s high temperature rating enabling proximity mounting to turbine thrust bearings.

- Centrifugal Compressor Surge Protection: Utilized on main refrigerant compressors in LNG liquefaction trains, the EPRO PR9268/300-000 measures shaft eccentricity during start-up, preventing damaging rub events through early detection of rotor bow.

- Hydroelectric Generator Guide Bearings: Applied on vertical shaft Francis turbines, the EPRO PR9268/300-000 monitors shaft runout during load rejection events, its waterproof construction permitting underwater operation during bearing maintenance floods.

- Paper Machine Roll Monitoring: Implemented on high-speed Yankee dryer rolls, this sensor detects journal cracking through shaft vibration signature analysis, with the EPRO PR9268/300-000‘s non-contact principle eliminating mechanical loading of monitored shafts.

Comparison with Competing Products

| Feature | EPRO PR9268/300-000 | Bentley Nevada 3300 XL 8mm | Emerson CSI 6500 |

|---|---|---|---|

| Sensitivity | 8.0 V/mm ±5% | 7.87 V/mm ±5% | 7.87 V/mm ±5% |

| Linear Range | 2.0 mm | 2.0 mm | 2.0 mm |

| Temperature Stability | ±0.05% FS/°C | ±0.1% FS/°C | ±0.1% FS/°C |

| Frequency Response | 0–10 kHz | 0–10 kHz | 0–10 kHz |

| Interchangeability | Yes (with EPRO drivers) | Yes (with 3300 XL drivers) | Calibration required |

| Hazardous Area Rating | ATEX Zone 2, CSA Div 2 | ATEX Zone 2, CSA Div 2 | ATEX Zone 2, CSA Div 2 |

| Marine Approval | Yes (DNV/GL) | Yes | Optional |

| Replacement Compatibility | Direct Bentley 3300 replacement | Native | Requires adapters |

| Typical Cost Position | Mid | High | Mid-High |

The EPRO PR9268/300-000 offers compelling value as a form-fit-function replacement for Bentley Nevada’s installed base, providing equivalent or superior technical specifications at significantly lower acquisition cost. While maintaining full mechanical and electrical compatibility with existing 3300 series cabling and monitoring systems, the EPRO PR9268/300-000 delivers improved temperature stability and interchangeability. Emerson’s CSI 6500 sensors, while technically capable, require adapter cables and recalibration when retrofitting to Bentley installations. The EPRO PR9268/300-000 represents the preferred solution for operators seeking to maintain Bentley Nevada infrastructure while reducing spare parts expenditure.

Selection Suggestions and Precautions

- System Compatibility Verification: Confirm that your signal conditioner or monitor is compatible with the EPRO PR9268/300-000‘s –4 to –20 V DC output characteristic; EPRO MMS 6000, CONCEPT, and Bentley Nevada 3300 series systems are directly compatible without modification.

- Target Material Consideration: The EPRO PR9268/300-000 calibration assumes AISI 4140 steel target material; for non-standard targets (stainless steel, aluminum, titanium), consult EPRO for sensitivity correction factors or custom calibration.

- Cable Length Matching: The EPRO PR9268/300-000 with integral 5-meter cable is optimized for this length; extension cables must be matched to maintain system frequency response and sensitivity, using only EPRO-specified coaxial extension assemblies.

- Installation Gap Setting: Install the EPRO PR9268/300-000 with nominal gap of 1.25 mm (approximately 1.25 V DC output), ensuring sufficient remaining linear range for full-scale vibration amplitudes plus DC shaft position changes.

- Hazardous Area Installation: For ATEX Zone 2 installations, verify that the EPRO PR9268/300-000 is installed per EPRO control drawing and connected only to certified associated apparatus with appropriate entity parameter matching.

- Environmental Protection: Although the EPRO PR9268/300-000 is IP68 rated, protect the connector interface from direct water impingement; apply dielectric silicone compound to threaded connectors and verify sealing gland integrity.

- Spare Parts Strategy: Given the EPRO PR9268/300-000‘s criticality in turbine protection systems and typical offshore or remote site locations, maintain site-specific calibrated spare units for each turbine, stored in climate-controlled environment.

- Obsolescence Management: The EPRO PR9268/300-000 remains in active production with committed 10-year availability; however, consider lifecycle status when specifying for new grassroots installations versus maintaining existing Bentley Nevada infrastructure.

- Calibration Interval: EPRO recommends 5-year recalibration interval for the EPRO PR9268/300-000 under normal operating conditions; facilities with frequent start-stop cycles or extreme temperatures should consider 3-year intervals.

- Mounting Hardware: Always use EPRO-supplied mounting brackets and gland fittings for the EPRO PR9268/300-000; non-standard mounting hardware may alter sensor grounding and introduce measurement errors or electrical noise susceptibility.

1SBP260001R1001 ABB PLC

GJV3075304R1 ABB

GJR5253300R3161 ABB PLC

GJR5251400R0101 ABB PLCPLC

GJR5251300R2171 ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922