Description

Product Overview

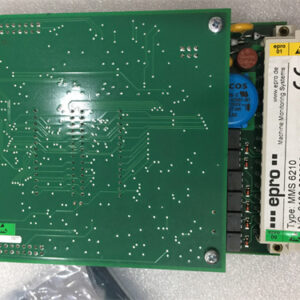

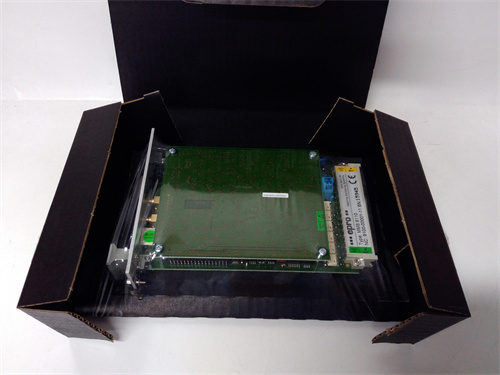

The EPRO MMS6110 is a high-precision, specialized monitoring module designed for the continuous protection and condition monitoring of rotating machinery, such as turbines, compressors, and large pumps. It is a core component of the EPRO PR 642x/PR 9268 series vibration monitoring system. This module is not a standard PLC I/O card but a dedicated proximitor (eddy current) driver and signal conditioner for non-contact vibration and position measurement. Its primary function is to supply a high-frequency radio frequency (RF) signal to a connected eddy current proximity probe, condition the returned signal, and output a precise DC voltage proportional to the gap between the probe tip and the observed metallic surface (shaft). For comprehensive technical data, installation manuals, and calibration procedures, please visit the official product resource: EPRO MMS6110. The EPRO MMS6110 is a critical component in machinery protection systems, providing essential data for measuring shaft vibration, axial position (thrust), and eccentricity to prevent catastrophic failures.

Product Parameters and Specifications

- Function: Proximitor / Eddy Current Sensor Driver and Conditioner.

- Input: Connects to a compatible EPRO PR 642x series or similar eddy current proximity probe (e.g., 5 mm or 8 mm probe).

- Output Signals: Provides two key, isolated analog outputs:

- DC Voltage Output: A -2 to -18 VDC (or 0 to -20 VDC) signal linearly proportional to the gap between the probe and the shaft (e.g., 2 V/mm or 200 mV/mil). This is the primary measurement for vibration or position.

- Gap Voltage (Demodulated RF) Output: A raw DC voltage representing the peak-to-peak amplitude of the RF signal, used for probe health diagnostics.

- Power Supply: Typically operates on -24 V DC (negative ground) as standard for the EPRO system.

- Frequency Response: Flat frequency response from 0 to 10 kHz or higher, suitable for capturing vibration signals from slow-roll to very high speeds.

- Linearity: High linearity (e.g., ±1% of full scale) within its specified measuring range (e.g., 2 mm).

- Sensitivity: Factory-calibrated to a specific value (e.g., 8.0 V/mm) which must match the connected probe.

- Termination: Mounts on a standard DIN rail and features screw terminals for power, probe connection, and output signals.

Advantages and Key Features

The EPRO MMS6110 offers critical advantages for reliable machinery monitoring. Its core feature is providing highly accurate and stable non-contact measurement, which is essential for detecting small changes in shaft position or vibration indicative of developing faults. The module ensures excellent temperature stability, minimizing drift in the measurement signal due to ambient temperature changes around the electronics. The provision of a dedicated gap voltage signal allows for continuous monitoring of probe health, detecting issues like cable degradation, connector problems, or probe coating. It is designed for robust operation in harsh industrial environments with high electromagnetic interference (EMI). As part of the established EPRO ecosystem, the MMS6110 guarantees compatibility and performance with EPRO probes, racks, and monitoring systems, ensuring a validated and supported measurement chain.

Application Cases in Industry

This module is a standard in industries with critical rotating equipment. In Power Generation (gas, steam, hydro turbines), multiple MMS6110 modules measure radial vibration on turbine bearings and axial displacement of the rotor. Within Oil & Gas, they monitor vibration on centrifugal and reciprocating compressors in refineries and on pipeline booster stations. For Petrochemical and Chemical plants, they protect large reactor agitator drives and synthesis gas compressors. The EPRO MMS6110 is also fundamental in Marine applications for monitoring main propulsion turbines and gearboxes. Essentially, any application where unplanned machinery failure leads to enormous safety or financial risk utilizes such protection systems.

Comparison with Competing Products

- vs. General-Purpose Analog Input Cards: A standard PLC/DCS analog card cannot power or condition an eddy current probe. The MMS6110 is a dedicated, intelligent signal conditioner that is essential for this specific sensor technology.

- vs. Other Machinery Monitoring System Cards (e.g., Bently Nevada 3300/3500 Proximitor, Vibro-Meter CPI 400): These are direct competitors. The EPRO MMS6110 competes on the basis of its performance specifications (linearity, temperature drift), its integration within the EPRO MMS 6000/7000 rack system, and its widespread acceptance in certain industries and geographic regions. Differences often lie in connector types, default sensitivity, and physical form factor.

- vs. Integrated Vibration Transmitters: Some systems use 4-20 mA loop-powered transmitters mounted at the probe. The MMS6110 is a card-based system offering centralized conditioning, easier calibration access, and direct gap voltage diagnostics which integrated transmitters may not provide.

Selection Suggestions and Precautions

- Selection Advice:

- Probe Compatibility: The EPRO MMS6110 must be matched with a compatible EPRO probe (PR 642x series). The probe’s sensitivity and required cable length must be known, as the module may need adjustment or a specific ordering code.

- System Integration: Ensure the module is compatible with your monitoring system’s rack (e.g., MMS 6350) and that the backplane provides the correct -24V DC power.

- Measurement Range: Select the module variant with the appropriate linear range (e.g., 2 mm) for your application. The gap must be set within this range during installation.

- Calibration Requirement: Modules are often pre-calibrated. Verify the calibration certificate matches your probe’s specifications. Keep this certificate for traceability.

- Important Precautions:

- Correct Power Supply Polarity: The EPRO system typically uses -24V DC (negative is common/ground). Applying positive 24V DC will destroy the module. Always verify polarity with a multimeter before connecting.

- Proper Probe Installation: The accuracy of the MMS6110 is entirely dependent on correct probe installation (gap setting, perpendicularity, and a clean, machined target area). Follow probe installation guidelines meticulously.

- Cable Integrity: Use only the specified, high-quality coaxial cables for the probe. Damaged cables or poor connectors are the most common source of signal noise and fault.

- Gap Voltage Monitoring: Continuously monitor the gap voltage signal in the control system. A sudden drop or erratic signal indicates a problem with the probe, cable, or the MMS6110 itself, and should be investigated immediately to avoid loss of protection.

3HAC14549-3/12A PLC

ABCC-DPV1 PLCDCSIPC

PM510V08 PLC

Notifier CPU2-640 PLC

2711-K5A5 PLC

1FK7042-5AF71-1EG2 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922