Description

EMERSON CE4050E1C2 is a high-performance digital input/output (I/O) module engineered for Emerson’s DeltaV distributed control system (DCS), serving as a versatile bridge between field devices and controllers in industrial automation. Designed to handle both discrete digital signals and critical control logic, this module excels in reliability, flexibility, and environmental resilience, making EMERSON CE4050E1C2 a preferred choice for oil & gas, chemical processing, power generation, and pharmaceutical industries. Whether controlling valves in a refinery, monitoring sensor states in a chemical plant, or enabling interlocks in a pharmaceutical facility, EMERSON CE4050E1C2 ensures fast, accurate signal transmission—laying the groundwork for safe and efficient operations. Its seamless integration with the DeltaV ecosystem and compatibility with third-party devices further solidify its role as a core component in modern industrial control systems.

Core Technical Specifications

| Category | Details |

|---|---|

| Device Type | Digital I/O module for Emerson DeltaV DCS |

| Core Function | Discrete signal acquisition (digital input) and control output (digital output) |

| Input Channels | 16 digital inputs (24V DC, sinking/sourcing, universal) |

| Output Channels | 16 digital outputs (relay, 2A/250V AC or 2A/30V DC) |

| Response Time | Input: ≤ 1 ms; Output: ≤ 5 ms |

| Communication Interface | DeltaV Serial Bus, Ethernet/IP (via DeltaV controller) |

| Power Supply | 24V DC (18-32V DC wide voltage range) |

| Operating Temperature | -40℃ ~ +70℃ |

| Protection Class | IP20 (cabinet mounting) |

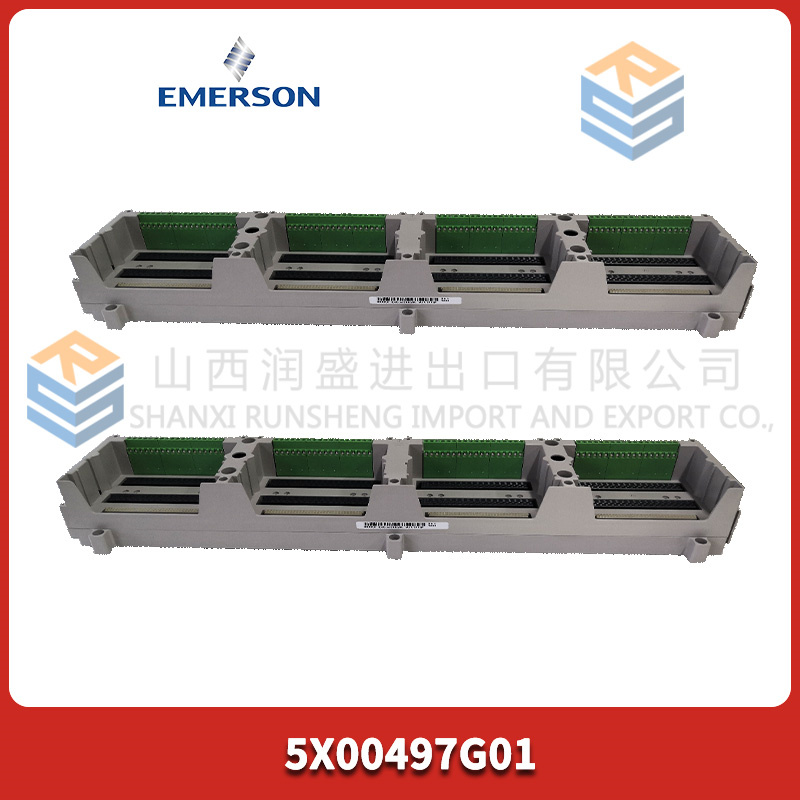

| Mounting Type | DIN rail mounting (compatible with DeltaV standard racks) |

| Dimensions (L×W×H) | 100mm × 150mm × 25mm |

| Compatibility | Emerson DeltaV controllers, DeltaV Explorer software, third-party 24V DC digital sensors/actuators |

| Certifications | CE, UL, CSA, IEC 61158, ATEX Zone 2, RoHS |

Key Advantages & Features

1. High Channel Density & Universal Signal Compatibility

EMERSON CE4050E1C2 packs 16 digital inputs and 16 digital outputs in a compact form factor, maximizing I/O density per unit space and reducing the number of modules needed for large-scale systems. The universal digital inputs support both sinking and sourcing configurations, while the relay outputs handle AC/DC loads—eliminating the need for dedicated input/output modules for different device types. This versatility simplifies system design and reduces integration complexity.

2. Fast Response & Reliable Signal Handling

With an input response time of ≤ 1 ms and output switching time of ≤ 5 ms, EMERSON CE4050E1C2 excels in time-sensitive applications such as emergency interlocks and rapid process adjustments. The module’s relay outputs feature robust contact ratings (2A/250V AC), ensuring reliable control of high-power actuators (e.g., solenoid valves, motor starters) without additional relays. Built-in surge protection safeguards the module against voltage spikes, enhancing long-term reliability.

3. Rugged Design for Harsh Industrial Environments

Engineered to withstand extreme operating conditions, EMERSON CE4050E1C2 operates reliably from -40℃ to +70℃, resisting vibrations up to 15G and shocks up to 20G. Its circuit board is coated with a conformal layer to protect against humidity (95% non-condensing), dust, and chemical vapors—making it suitable for offshore platforms, desert refineries, and high-temperature manufacturing facilities. The wide voltage input (18-32V DC) accommodates unstable power grids, further extending its applicability.

4. Seamless DeltaV Integration & User-Friendly Operation

The module integrates seamlessly with Emerson DeltaV DCS, supporting plug-and-play configuration via DeltaV Explorer software. Technicians can easily map channels, set up interlock logic, and monitor module status remotely—reducing setup time and operational complexity. Front-panel LED indicators provide clear visibility of power status, channel activity, and fault conditions (e.g., output overload, input short circuit), enabling quick troubleshooting without specialized tools.

5. Enhanced Durability & Low Maintenance

Constructed with industrial-grade components and rigorously tested for durability, EMERSON CE4050E1C2 offers a service life of over 15 years under normal operating conditions. The relay outputs are rated for 100,000 switching cycles, minimizing replacement frequency. The module supports hot-swapping, allowing replacement during system operation to avoid unplanned downtime—lowering maintenance costs and improving overall system availability.

Application Scenarios & Case Studies

1. Oil & Gas: Refinery Valve Control & Interlock

A large petroleum refinery deployed 24 units of EMERSON CE4050E1C2 to control 384 valves and monitor 384 sensor states (e.g., valve position, pressure switches) in its distillation units. The module’s fast response time (≤1 ms input) ensured rapid interlock activation when a pressure switch detected an overpressure condition, closing critical valves in 8 ms to prevent a column rupture. The relay outputs reliably handled the valves’ 24V DC solenoid loads, and the module’s rugged design withstood the refinery’s high-temperature (65℃) and high-vibration environment—saving the refinery over $600,000 in potential equipment damage.

2. Chemical Processing: Batch Reactor Sequence Control

A chemical plant used EMERSON CE4050E1C2 to manage the sequence control of 12 batch reactors, controlling feed pumps, agitators, and discharge valves via digital outputs and monitoring process states via digital inputs. The module’s high channel density reduced the number of required modules by 30%, simplifying cabinet layout. During a batch run, the module detected a feed pump failure via a digital input and triggered an immediate shutdown sequence—preventing off-spec product and avoiding $250,000 in batch losses.

3. Power Generation: Boiler Safety Interlock

A 600MW coal-fired power plant integrated EMERSON CE4050E1C2 into its boiler safety system, monitoring flame detectors, water level switches, and draft fan status. The module’s universal inputs simplified integration with mixed sinking/sourcing sensors, while its relay outputs controlled emergency shutdown valves and fan starters. When a flame detector failed, the module’s fault diagnostics alerted operators, and the DeltaV DCS automatically bypassed the faulty sensor to maintain system availability—avoiding a potential boiler shutdown worth $400,000 in lost generation.

Competitor Comparison

| Comparison Dimension | EMERSON CE4050E1C2 | Competitor (e.g., Yokogawa FA-M3 Digital I/O) |

|---|---|---|

| Channel Density | 16 in/16 out | 12 in/12 out |

| Response Time | Input ≤1 ms; Output ≤5 ms | Input ≤2 ms; Output ≤8 ms |

| Output Contact Rating | 2A/250V AC | 1A/250V AC |

| Operating Temperature | -40℃ ~ +70℃ | -20℃ ~ +60℃ |

| Hot-Swapping | Full support | Limited support |

| DCS Compatibility | Emerson DeltaV (native) | Multi-vendor (limited native integration) |

Selection Recommendations & Usage Notes

Selection Recommendations

- DeltaV Ecosystem Deployments: Prioritize EMERSON CE4050E1C2 for existing Emerson DeltaV DCS users, leveraging native integration and plug-and-play functionality.

- High-Density I/O Requirements: Choose for applications needing maximum digital I/O channels per module (e.g., valve banks, sensor arrays) to reduce cabinet space and cost.

- Harsh Environment Operations: Deploy in offshore, high-temperature, or high-vibration settings, thanks to its rugged design and wide operating range.

- Time-Sensitive Interlocks: Ideal for emergency shutdowns, batch sequence control, and rapid process adjustments requiring fast response times.

Usage Notes

- Installation: Mount on a secure DIN rail in a sealed control cabinet; maintain ≥5cm spacing from high-power devices (e.g., inverters) to avoid electromagnetic interference. Ensure proper ventilation to keep temperatures within -40℃ ~ +70℃.

- Wiring: Use shielded twisted-pair cables for input signals; ground the shield at one end (ground resistance ≤4Ω). For output wiring, use 1.5mm² cables to handle maximum load current (2A).

- Configuration: Use DeltaV Explorer software to map channels, set up fault diagnostics, and configure interlock logic. Test output loads to ensure they do not exceed the 2A contact rating.

- Maintenance: Regularly inspect LED indicators and DeltaV fault logs to detect overloads or short circuits. Replace relays or the entire module if output switching becomes unreliable. Perform hot-swaps only when the system is in a safe state.

- Spare Parts: Reserve 1-2 spare modules for critical production lines; store in a dry, temperature-controlled environment (0-40℃) to ensure readiness.

- CE4050E1C2

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922