Description

EMERSON CSI6210: Comprehensive Analysis of Emerson’s Precision Machinery Protection Monitor

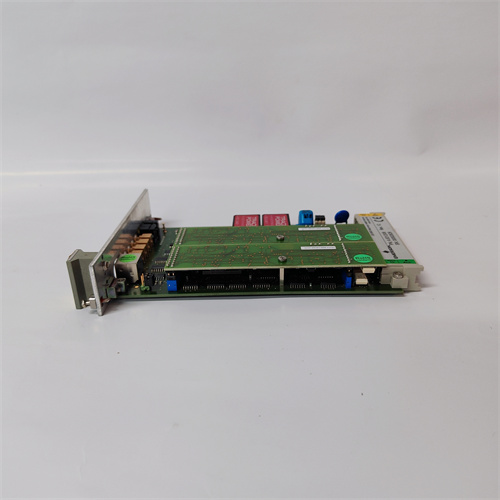

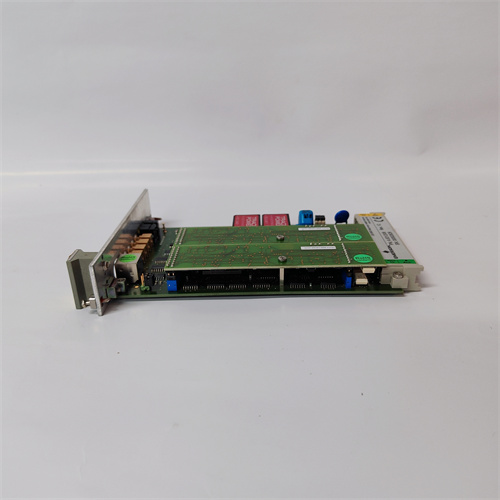

The primary focus of this analysis is EMERSON CSI6210—a high-performance machinery protection monitor developed by Emerson, specifically designed to safeguard critical rotating equipment (such as turbines, compressors, and motors) in industrial environments. As a core component of Emerson’s CSI 6500 Machinery Health™ Monitoring System, EMERSON CSI6210 continuously monitors key mechanical parameters (including vibration, temperature, and rotor position) and triggers real-time alarms or shutdowns when thresholds are exceeded, preventing catastrophic equipment failure. Whether deployed in power plants, refineries, or manufacturing facilities, EMERSON CSI6210 delivers reliable, actionable insights into machinery health, making it an indispensable tool for predictive maintenance and operational safety. Detailed technical documentation and product inquiries can be accessed via the EMERSON CSI6210 official reference link.

Core Product Parameters

- Monitoring Channels & Parameters: Equipped with 4 independent monitoring channels, supporting vibration (radial/axial), temperature (RTD/thermocouple), rotor speed, and position measurements; each channel can be configured for specific parameter types via software.

- Measurement Specifications:

- Vibration: Measurement range 0–254 μm (peak), frequency range 10 Hz–10 kHz, accuracy ±1% of full scale.

- Temperature: Supports Pt100 RTD (range -200°C–850°C) and Type K/J thermocouples (range -200°C–1372°C), accuracy ±0.5°C.

- Speed: Measurement range 0–100,000 RPM, accuracy ±0.1% of reading.

- Alarm & Shutdown Functionality: Configurable dual-level alarms (Alert/Warning) and trip/shutdown outputs; 4 relay outputs (Form C, 250 VAC/30 VDC, 5 A) for triggering external safety devices or control systems.

- Communication & Integration: Supports Modbus RTU/TCP, HART, and OPC UA protocols; compatible with Emerson’s AMS Device Manager software and third-party DCS/PLC systems (e.g., Siemens S7, Allen-Bradley ControlLogix).

- Operating Environment: Operating temperature range -40°C–70°C, storage temperature -40°C–85°C; relative humidity 5%–95% (non-condensing); vibration resistance 2 g (10 Hz–500 Hz), shock resistance 25 g (11 ms, half-sine wave); compliant with API 670, ISO 10816, and IEC 61508 SIL 2 safety standards.

- Power Requirements: Input voltage 18–32 VDC (redundant power input supported), typical power consumption 15 W (full load), standby power consumption ≤3 W.

Advantages and Core Features

- Precision Machinery Health Monitoring: EMERSON CSI6210 leverages advanced sensing technology to deliver high-accuracy measurements of vibration, temperature, and speed, enabling early detection of mechanical anomalies (e.g., bearing wear, rotor imbalance, misalignment) before they escalate into major failures. Its wide frequency range ensures compatibility with both low-speed and high-speed rotating equipment.

- Robust Industrial Design: Built to withstand harsh industrial conditions, EMERSON CSI6210 features a ruggedized metal chassis, wide operating temperature range, and resistance to vibration and electromagnetic interference (EMI). Redundant power input and fault-tolerant circuitry enhance system reliability, ensuring uninterrupted monitoring even in critical environments (Mean Time Between Failures, MTBF ≥ 120,000 hours).

- Seamless Integration with Emerson Ecosystem: As part of Emerson’s CSI 6500 system, EMERSON CSI6210 integrates seamlessly with AMS Device Manager software, enabling centralized configuration, data logging, and predictive maintenance analytics. It also supports remote monitoring and firmware updates, reducing the need for on-site intervention and lowering maintenance costs.

- Flexible Configuration & User-Friendly Interface: The monitor offers intuitive software-based configuration (via USB or Ethernet) and a local LCD display with keypad for on-site parameter adjustments and status checks. Customizable alarm thresholds and trip logic allow tailoring to specific equipment requirements, while real-time status indicators (LEDs) provide instant visibility into channel health and alarm states.

- Compliance with Industry Standards: EMERSON CSI6210 meets strict industry standards for machinery protection, including API 670 (for rotating equipment in petroleum and gas industries) and ISO 10816 (for vibration evaluation of industrial machines). Compliance with IEC 61508 SIL 2 ensures it can be safely integrated into safety instrumented systems (SIS) for critical applications.

Industry Application Scenarios

- Power Generation: In a coal-fired power plant, EMERSON CSI6210 monitors the vibration and temperature of steam turbine rotors and generator bearings. It continuously transmits data to the plant’s DCS via Modbus TCP, triggering an alert if vibration exceeds 125 μm (warning) or initiating an emergency shutdown if levels reach 200 μm (trip). This proactive protection prevents turbine damage and avoids costly unplanned outages.

- Oil & Gas Refining: In a petroleum refinery, the monitor is deployed on centrifugal compressors used in crude oil distillation. EMERSON CSI6210 tracks radial vibration, bearing temperature, and rotor speed, integrating with the refinery’s SIS via HART protocol. If bearing temperature exceeds 120°C or vibration spikes due to surge, the monitor activates a relay to shut down the compressor, preventing seal failure and hydrocarbon leaks.

- Manufacturing: In an automotive assembly plant, EMERSON CSI6210 monitors the health of large electric motors driving conveyor systems and robotic arms. It detects early signs of motor bearing degradation (via increased vibration) and sends alerts to maintenance teams via AMS Device Manager, enabling scheduled repairs before motor failure disrupts production.

- Marine & Offshore: On an offshore drilling rig, the monitor protects marine diesel engines by monitoring crankshaft vibration, cylinder head temperature, and turbocharger speed. Its rugged design withstands salt spray, extreme temperatures, and high vibration, ensuring reliable operation in harsh offshore conditions.

Competitive Advantages

- vs. Generic Machinery Monitors (e.g., Bently Nevada 3500/60): EMERSON CSI6210 offers superior integration with Emerson’s predictive maintenance software (AMS Device Manager), providing advanced analytics and remote monitoring capabilities that generic monitors lack. It also supports more communication protocols (including OPC UA) for seamless integration with modern digital systems, whereas legacy monitors may be limited to proprietary protocols.

- vs. Emerson’s Entry-Level Monitor (e.g., CSI6100): Compared to the CSI6100, EMERSON CSI6210 provides more monitoring channels (4 vs. 2), higher measurement accuracy, and support for SIL 2 safety compliance. It also offers advanced features such as vibration waveform capture and trend analysis, making it suitable for critical equipment, while the CSI6100 is better suited for basic protection needs.

- vs. Third-Party Monitors (e.g., SKF Microlog CMXA): EMERSON CSI6210 delivers tighter integration with Emerson’s broader machinery health ecosystem (including sensors, software, and services), ensuring consistent data flow and simplified system management. Its compliance with API 670 and SIL 2 standards makes it more suitable for regulated industries (e.g., oil & gas, power), whereas third-party monitors may lack these certifications.

Selection Recommendations and Precautions

- Selection Recommendations: Choose EMERSON CSI6210 for protecting critical rotating equipment in regulated industries (power, oil & gas, petrochemicals) where compliance with API 670/ISO 10816 and SIL 2 safety standards is required. It is also ideal for facilities implementing predictive maintenance programs, as its integration with AMS Device Manager enables advanced analytics. For non-critical equipment or basic protection needs, consider Emerson’s CSI6100 or cost-effective generic alternatives.

- Installation Precautions: Install the monitor in a temperature-controlled, vibration-free control cabinet (away from high-voltage equipment) to ensure measurement accuracy. Use shielded cables for sensor connections (minimum distance of 15 cm from power cables) to reduce EMI interference. Ensure proper grounding (ground resistance ≤ 4 Ω) and verify sensor calibration before commissioning.

- Configuration & Programming Precautions: Use AMS Device Manager to configure alarm thresholds, trip logic, and communication parameters, ensuring alignment with equipment manufacturer specifications. Test alarm and shutdown functions during commissioning to confirm proper relay operation. Enable data logging to capture historical trends, which are critical for predictive maintenance analysis.

- Maintenance Precautions: Regularly calibrate connected sensors (annually or per manufacturer recommendations) to maintain measurement accuracy. Inspect relay contacts and wiring connections periodically for corrosion or wear. Update firmware to the latest version via AMS Device Manager to access new features and security patches. Backup configuration settings to facilitate quick recovery in case of module failure. Avoid modifying safety-related parameters (e.g., trip thresholds) without proper authorization, as this may compromise equipment protection.

CSI6210

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922