Description

Product Overview

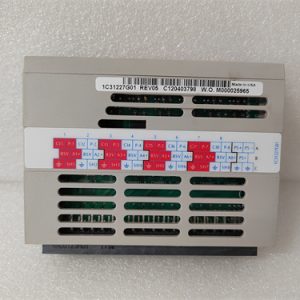

The core product to be introduced is EMERSON A6410 (Product Link: [Insert Link]), an industrial-grade analog output module developed by Emerson, specifically designed for integrating with Emerson DeltaV DCS and Rosemount process instrumentation. EMERSON A6410 is engineered to transmit precise analog control signals (e.g., 4–20 mA, 0–10 V) to final control elements such as control valves, variable frequency drives (VFDs), and actuators, making it a critical component in oil & gas, chemical, and pharmaceutical industries. With its high signal stability and built-in diagnostic capabilities, EMERSON A6410 ensures reliable regulation of key process parameters (e.g., flow, pressure, temperature), minimizing process fluctuations and improving production efficiency. Additionally, EMERSON A6410 offers seamless compatibility with Emerson’s process automation ecosystem, eliminating the need for third-party adapters and simplifying on-site integration.

Technical Specifications

- Device Type: Industrial analog output module for process control systems

- Number of Channels: 4 independent, isolated analog output channels

- Supported Signal Types: 4–20 mA DC (default), 0–10 V DC (configurable per channel)

- Output Accuracy: ±0.05% of full scale (FS) at 25°C; temperature drift ≤ 100 ppm/°C

- Maximum Output Current: 0.5 A per channel (for 4–20 mA signals); overcurrent protection triggers at 0.6 A

- Isolation: Galvanic isolation (2500 V AC) between channels and between the module and system backplane

- Operating Environment: Temperature range -40°C to +70°C; humidity 5%–95% (non-condensing)

- Power Supply: 24 V DC (redundant input design, voltage range 19.2 V–28.8 V); power consumption ≤ 8 W

- Dimensions: 95 mm × 120 mm × 30 mm (L × W × H), compatible with standard 19-inch racks

- Protection Rating: IP20 (suitable for cabinet-mounted installation)

- Mounting Method: DIN rail mounting or 19-inch rack mounting (via adapter kit)

- Additional Features: Channel-level short-circuit protection, LED status indicators (power, signal, fault), online configuration via Emerson DeltaV Explorer, and fault code storage (retrievable via DCS)

Core Advantages & Features

- High Signal Precision and Stability: With an accuracy of ±0.05% FS and low temperature drift, EMERSON A6410 delivers consistent control signals to final elements—critical for applications like pharmaceutical batch processing, where even minor signal deviations can affect product quality.

- Redundant Design for Reliability: The redundant 24 V DC power input and galvanic isolation between channels ensure EMERSON A6410 remains operational even if one power source fails or a single channel shorts. This meets the “zero downtime” requirements of continuous processes (e.g., oil refinery distillation columns).

- Seamless Integration with Emerson Ecosystem: EMERSON A6410 auto-detects and configures with Emerson DeltaV DCS and Rosemount transmitters, supporting plug-and-play functionality. This eliminates manual driver installation and reduces on-site commissioning time by up to 40%.

- Comprehensive Diagnostics: Built-in short-circuit protection and fault code storage allow maintenance teams to quickly identify issues (e.g., a blocked control valve causing signal overload) via the DeltaV DCS. LED indicators also provide at-a-glance status checks without needing to connect to software.

- Extreme Environment Adaptability: Operating in -40°C to +70°C, EMERSON A6410 performs reliably in harsh conditions such as arctic oil fields (low temperatures) or chemical plant reactors (high temperatures), without requiring additional heating or cooling equipment.

Application Scenarios

- Oil & Gas (Upstream Production): EMERSON A6410 transmits 4–20 mA signals from DeltaV DCS to downhole control valves, regulating oil flow based on pressure data from Rosemount transmitters. Its galvanic isolation resists electromagnetic interference from drilling equipment, ensuring stable valve operation.

- Chemical Processing: In ethylene production plants, the module controls VFDs for compressor speed (via 4–20 mA signals), maintaining optimal pressure in reaction vessels. Short-circuit protection prevents damage if a VFD malfunctions, avoiding unplanned shutdowns.

- Pharmaceutical Manufacturing: For bioreactor temperature control, EMERSON A6410 sends 0–10 V signals to heating/cooling actuators. Its high accuracy ensures temperature fluctuations stay within ±0.1°C, complying with FDA GMP standards for drug production.

- Water & Wastewater Treatment: The module regulates diaphragm valves for chemical dosing (e.g., chlorine disinfection) by transmitting 4–20 mA signals. Its wide temperature range adapts to outdoor pump stations, while redundant power ensures uninterrupted dosing even during power glitches.

Competitor Comparison

| Comparison Dimension | EMERSON A6410 | Siemens 6ES7332-5HF00-0AB0 | Rockwell 1756-OF8H |

|---|---|---|---|

| Number of Channels | 4 | 8 | 8 |

| Output Accuracy | ±0.05% FS | ±0.1% FS | ±0.08% FS |

| Isolation Voltage | 2500 V AC | 1500 V AC | 2000 V AC |

| Operating Temperature Range | -40°C to +70°C | 0°C to +60°C | -25°C to +70°C |

| Compatible Ecosystem | Emerson DeltaV/Rosemount | Siemens S7-400/PCS 7 | Rockwell ControlLogix |

| Redundant Power Input | Supported | Not supported | Supported |

| Approx. Price (USD) | $650–$750 | $500–$600 | $600–$700 |

Key Differences: EMERSON A6410 outperforms competitors in signal accuracy, isolation voltage, and DeltaV ecosystem integration—ideal for industries relying on Emerson’s process control solutions. Siemens and Rockwell modules offer more channels but lack the same level of precision and environmental resilience.

Selection Recommendations

- Prioritize Emerson Ecosystem Compatibility: If your site uses Emerson DeltaV DCS or Rosemount instruments, EMERSON A6410 is the optimal choice to avoid compatibility issues and reduce integration costs.

- Consider Precision Requirements: For applications requiring ±0.1% FS accuracy (e.g., pharmaceuticals, fine chemicals), EMERSON A6410’s ±0.05% FS precision is superior to competitors.

- Evaluate Environmental Conditions: In extreme temperatures (-40°C to +70°C) or high-interference environments (e.g., oil drilling), EMERSON A6410’s isolation and wide temperature range make it more reliable than Siemens’ 0°C–60°C modules.

- Assess Redundancy Needs: For continuous processes (e.g., refineries), select EMERSON A6410’s redundant power design to prevent downtime—unlike Siemens modules that lack this feature.

Usage Precautions

- Match Signal Type to Equipment: Configure channels for 4–20 mA (for valves/VFDs) or 0–10 V (for actuators) per the final element’s requirements. Mismatched signals may cause equipment damage or erratic operation.

- Ensure Proper Grounding: Connect the module’s ground terminal to a dedicated earth ground (resistance ≤ 4Ω) to maximize electromagnetic interference resistance. Avoid sharing grounds with power cables.

- Avoid Overloading Channels: Do not exceed the 0.5 A maximum output current. For high-current devices (e.g., large valves), use an external signal amplifier to protect EMERSON A6410’s internal circuits.

- Regular Calibration: Calibrate the module annually using Emerson’s DeltaV Calibration Manager to maintain accuracy. Skip calibration may lead to process deviations over time.

- Use Genuine Replacements: Only replace faulty units with original EMERSON A6410 modules. Third-party alternatives may not meet Emerson’s isolation or accuracy standards, risking DCS compatibility issues.

A6410

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922