Description

Product Overview and Introduction

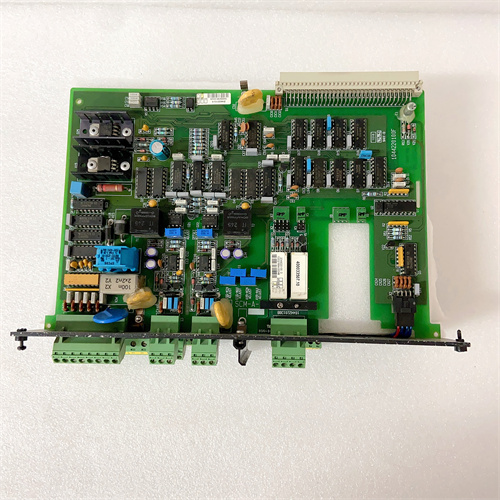

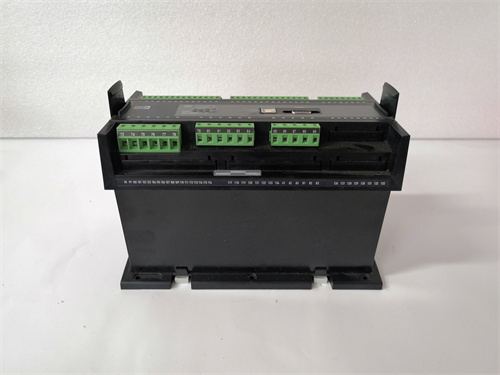

The DEIF OPM-1 1044220080E is a specialized, high-performance optical power meter module designed for precision measurement within industrial and marine power management systems. As a core component from DEIF’s instrumentation range, this device is engineered to accurately monitor optical signals, typically from engine speed sensors or other critical optoelectronic devices, converting them into reliable electrical data for control units. The DEIF OPM-1 1044220080E ensures the integrity of speed and timing measurements, which are fundamental for synchronizing generators, governing engine speed, and protecting prime movers in demanding environments.

Detailed Product Parameters and Specifications

The technical operation of the OPM-1 1044220080E is defined by precise electrical and optical specifications:

- Primary Function: Optical-to-Electrical Signal Converter/Power Meter. It receives a modulated optical signal (typically from a fiber optic sensor or encoder) and outputs a corresponding, conditioned electrical signal.

- Input Type: Fiber optic input, with specifications for connector type (e.g., ST, SMA), wavelength acceptance (commonly 660nm or 820nm for industrial sensors), and minimum detectable optical power.

- Output Signal: Provides a digital pulse signal (e.g., TTL, HTL) or a proportional analog signal (0-10V, 4-20mA) representing the frequency or intensity of the incoming light, suitable for PLC or governor input.

- Supply Voltage: Operates on a standard industrial DC supply voltage, typically 24 V DC, with defined tolerances.

- Frequency Range: Capable of accurately processing input signal frequencies up to a specified maximum (e.g., 20 kHz), covering the operational range of most speed sensing applications.

- Response Time: Very fast response time, crucial for real-time control and protection functions.

- Environmental Ratings: Designed to withstand industrial and marine conditions, with high resistance to vibration, temperature fluctuations, and electromagnetic interference (EMI).

- Mounting: Typically designed for DIN-rail mounting within a control cabinet.

Key Advantages and Distinctive Features

The DEIF OPM-1 1044220080E module provides critical benefits for control and protection systems:

- High Immunity to Noise: Utilizing fiber optic input provides complete galvanic isolation and makes the signal transmission immune to electromagnetic interference (EMI/RFI), which is paramount in electrically noisy environments like engine rooms or switchyards.

- Exceptional Accuracy and Reliability: Delivers precise and stable signal conversion, which is essential for accurate speed measurement, ensuring reliable generator synchronization and engine protection against overspeed.

- Robust Industrial Design: Built to endure harsh conditions, including high levels of vibration and wide temperature ranges, ensuring long-term reliability.

- Fast Response: Its quick signal processing capability enables real-time control actions, allowing for immediate governor response or trip signals for protective functions.

- System Integration: Designed to seamlessly integrate with DEIF’s range of generator control units (GCUs), power management systems (PMS), and governors, providing a cohesive and reliable solution. The consistent performance of the DEIF OPM-1 1044220080E makes it a trusted component in mission-critical power generation setups.

Application Scenarios and Case Studies

This optical interface module is essential in applications where reliable speed sensing is non-negotiable:

- Marine Power Generation: On ships, it connects fiber-optic speed sensors on main and auxiliary diesel engines to the governor and power management system for load sharing, synchronization, and overspeed protection.

- Power Plant Control: In diesel or gas engine-based power plants, it provides the critical speed feedback signal for isochronous load control and frequency regulation.

- Heavy Industry: Used for monitoring turbine speed or large compressor shaft speed where EMI from high-power drives would corrupt standard electrical signals.

- Hybrid & Microgrid Systems: Ensures precise speed measurement for generator sets participating in islanded or grid-parallel operations.

A common application case is the retrofit of a vessel’s power management system, where the existing magnetic speed sensors were replaced with fiber-optic ones connected to the DEIF OPM-1 1044220080E. This upgrade eliminated sporadic speed signal errors caused by EMI, leading to smoother synchronization and eliminating false overspeed alarms.

Comparison with Competing Products

Compared to similar optical interface modules from competitors like Woodward, BASLER, or other control system manufacturers, the DEIF OPM-1 1044220080E holds specific strengths:

- Native DEIF Ecosystem Integration: It offers plug-and-play compatibility and optimized performance with DEIF controllers and software, reducing integration complexity and engineering time.

- Marine & Harsh Environment Focus: DEIF’s core expertise in maritime applications is reflected in the module’s ruggedness and certifications, often giving it an edge in shipboard applications over more generically industrial competitors.

- Signal Integrity: Its design prioritizes signal fidelity in the presence of noise, a critical factor where competing modules using standard electrical interfaces might fail.

Competitors may offer modules with wider input voltage ranges, different form factors, or lower cost for less demanding applications. The choice often depends on the existing control system brand and the specific environmental challenges.

Selection Guidelines and Important Considerations

Selecting and implementing this module requires careful planning:

- Confirm System Compatibility: The DEIF OPM-1 1044220080E must be compatible with the host controller (e.g., a specific DEIF GCU or governor). Verify the supported module list in the controller’s manual.

- Match Optical Specifications Precisely: This is critical. The module’s wavelength (e.g., 660nm), connector type, and required optical power input must exactly match the specifications of the fiber optic sensor or encoder it will be connected to.

- Verify Signal Output Type: Ensure the module’s electrical output signal type (e.g., TTL pulses, 4-20mA) is correctly configured and matches the input requirements of the receiving device (PLC, governor card).

- Environmental Suitability: Confirm the operating temperature and vibration specifications meet or exceed the conditions of the installation environment.

- Installation and Calibration: Use high-quality fiber optic cables, avoid sharp bends, and ensure clean connections. Some units may require calibration or configuration via DIP switches. Always consult the official manual for the OPM-1 1044220080E, available through the product link, before installation.

- Safety and Wiring: Follow proper electrical isolation procedures. Ensure the power supply is clean and protected. The fiber optic system itself is intrinsically safe in explosive atmospheres, but the electrical side must be installed according to relevant standards.

5X00241G02 PRO PLC EMERSON

IOIC 5X00226G02 IOIC EMERSON

24VDC 5X00489G01 PDA EMERSON

24VDC 1X00781H01LPS PLC EMERSON

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922