Description

Product Name

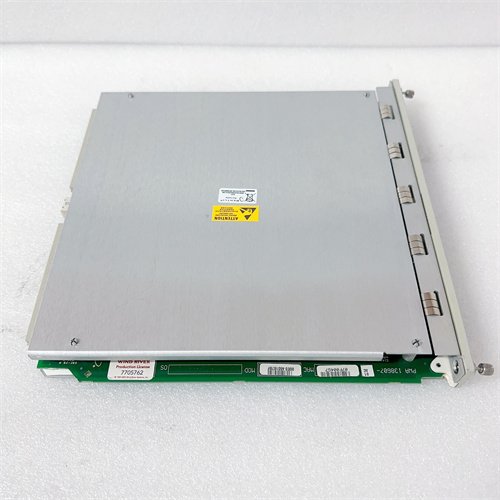

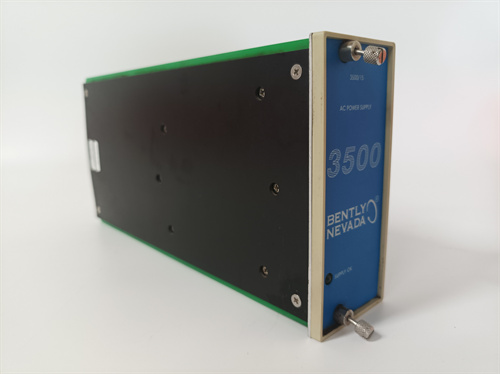

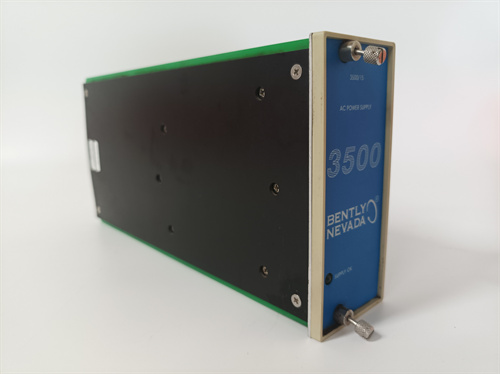

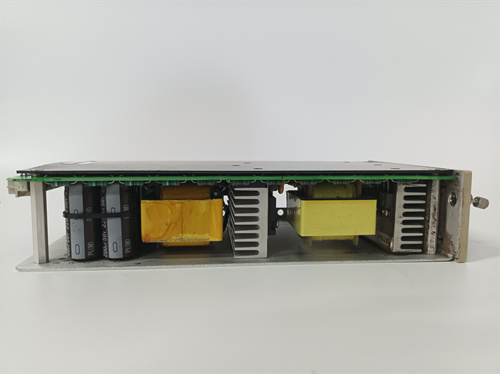

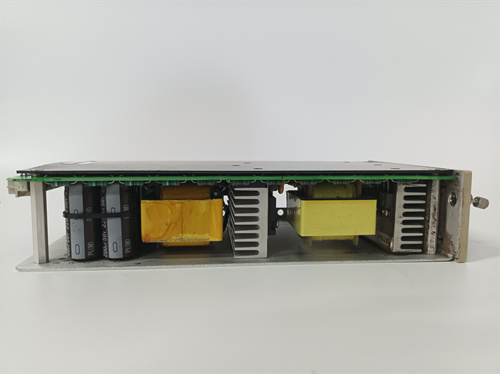

BENTLY 3500/15 and BENTLY 3500/20

Product Description

The BENTLY 3500/15 and BENTLY 3500/20 are cutting-edge monitoring systems designed for machinery protection and condition monitoring. These models are part of the BENTLY 3500 series, known for their advanced technology and reliability in industrial applications. The BENTLY 3500/15 specifically focuses on machinery vibration monitoring, while the BENTLY 3500/20 serves as a comprehensive rack that supports multiple input channels for various sensors. Both models are engineered to enhance operational efficiency by providing real-time data and alerts, ensuring that machinery operates within its safe limits.

Product Specifications

- BENTLY 3500/15:

- Vibration monitoring for rotating equipment

- Supports a variety of vibration sensors

- Provides analog and digital output signals

- Integration with other BENTLY 3500 modules

- BENTLY 3500/20:

- Multi-channel input rack

- Capable of supporting various modules for temperature, pressure, and speed monitoring

- User-friendly interface for configuration and monitoring

- Highly adaptable to different industrial environments

Advantages and Features

The BENTLY 3500/15 and BENTLY 3500/20 offer several advantages:

- Reliable Performance: Both models provide consistent monitoring and data acquisition, which are essential for predictive maintenance.

- Flexibility: The BENTLY 3500/20 can accommodate various types of sensors, making it versatile for different applications.

- User-friendly: The systems feature intuitive interfaces that simplify setup and monitoring processes.

- Scalability: As part of the BENTLY 3500 series, these models can be easily integrated into existing systems, allowing for future expansion.

Application Fields and Case Studies

The BENTLY 3500/15 and BENTLY 3500/20 are extensively used in a wide range of industrial sectors:

- Oil and Gas: Monitoring pumps and compressors to prevent failures and costly downtime.

- Power Generation: Ensuring the reliability of turbine operations through constant performance checks.

- Manufacturing: Detecting vibrations in heavy machinery to enhance productivity and operational safety.

In a recent case study, a major oil refinery implemented the BENTLY 3500/15 and BENTLY 3500/20 systems, resulting in a 30% reduction in unplanned maintenance costs. The real-time monitoring capabilities enabled the maintenance team to address potential issues before they escalated into significant problems.

Competitor Comparison

When compared to other similar systems, such as those from Siemens or Rockwell Automation, the BENTLY 3500/15 and BENTLY 3500/20 stand out in the following areas:

- Accuracy: Advanced algorithms for data collection and analysis provide highly accurate readings.

- Integration: Seamless integration with other BENTLY systems enhances monitoring capabilities compared to competitors’ offerings that may require additional configuration.

- Support: BENTLY offers extensive technical support and resources to ensure optimal system performance.

Selection Recommendations

When selecting the BENTLY 3500/15 and BENTLY 3500/20, consider the following:

- System Requirements: Assess your specific monitoring needs and determine which sensors are essential for your application.

- Compatibility: Ensure that the chosen model(s) can adequately integrate with your existing infrastructure.

- Scalability Needs: Plan for potential future expansions by selecting models compatible with additional modules and sensors.

Precautions

- Always follow the manufacturer’s guidelines for installation and calibration to ensure optimal performance of the BENTLY 3500/15 and BENTLY 3500/20 systems.

- Regular maintenance checks are crucial to maintaining accuracy and reliability.

- Ensure that the appropriate environmental conditions are met to prevent damage to equipment.

We are your trusted partner. We offer sales and technical support for product models like BENTLY 3500/15 and BENTLY 3500/20 as well as other automation spare parts. Enjoy our special discounted prices. Please contact us, and we will be happy to serve you.

BENTLY+3500/15 3500/20

A-B 1746-IB32

SCHNEIDER LV430630P

A-B 1756-IB32/B

A-B 1756-DNB

SIEMENS 6ES5420-4UA14

FOXBORO FBM207B P0916JS

SIEMENS 6ES5420-4UA14

SCHNEIDER 140DRA84000

A-B 1756-IB32/B

SICK I10-M0233

MODICON AS-BDEP-216

PILZ PILZ 774150

ABB ZMU-02/3AXD50000006010

SCHNEIDER 140DAO84000

A-B 1746-A13

Advantech PCA-6773

FOXBORO P0916CC

SCHNEIDER 140DD035300

A-B 1756-A10

SCHNEIDER 170AAI14000

GE IC693CHS398

A-B 1756-IB32

A-B 1756-IB32

A-B 1756-IB32/B

台达 NPS-400AB B

ABB CI801

GE IC693PWR321

A-B 440G-T27129

FANUC A860-2005-T301

Bently 330130-040-00-00

SIEMENS 6EP1336-3BA00

Schneider TSX3722001

A-B 1756-IB32

A-B 1756-A7

Schneider TSXDMZ28DR

A-B 22F-D4P2N113

SIEMENS 6ES5420-4UA14

SCHNEIDER 170ADO35000

FOXBORO P0400HH

ABB RDCO-01C

FOXBORO P0916AA

A-B 1769-IQ32

ABB DO802

SIEMENS 3VL9440-7DC30

GE IC200MDL750

SIEMENS 6ES7322-1BH01-OAAO

AB 1769-0B16P

ABB “1SVR011712R1700 ”

A-B 1756-OB32

A-B 193-EIOGP-42-24D

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922