Description

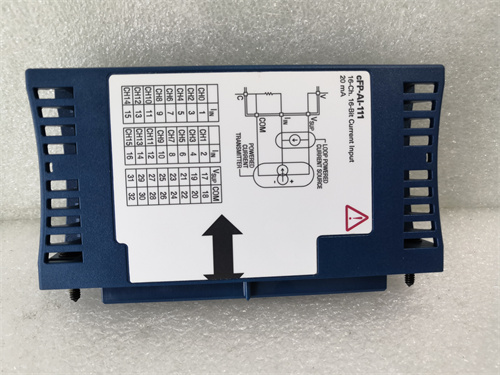

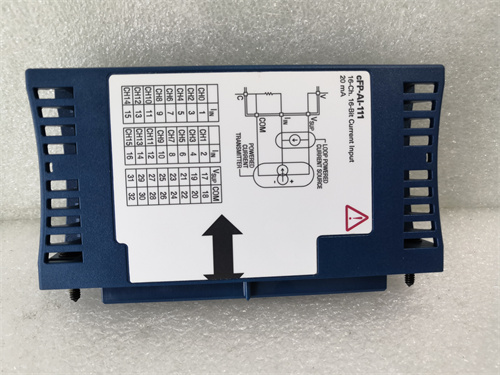

Product Overview of BENTLY CFP-AI-111

In the field of industrial equipment condition monitoring—especially for ensuring the safe operation of rotating machinery such as turbines, compressors, and generators—the BENTLY CFP-AI-111 analog input module stands as a core component. Developed by Bently Nevada (a leading brand in rotating machinery diagnosis and protection systems, now part of the GE Group), this module is designed to accurately collect and convert analog signals from various sensors (e.g., vibration sensors, shaft position sensors, temperature sensors) into digital data. This data is then transmitted to control systems, providing critical support for equipment health analysis, fault early warning, and emergency protection. For complete functional descriptions, technical details, and integration solutions of the BENTLY CFP-AI-111, refer to the official resource: [BENTLY CFP-AI-111 Product Link](Your provided link will be inserted here). As a classic module under Bently Nevada, the BENTLY CFP-AI-111 inherits the brand’s 60+ years of technical expertise in rotating machinery protection. Even in harsh industrial environments with high vibration and temperature (e.g., power plants, oil and gas fields), it maintains stable data acquisition performance, effectively preventing production losses caused by sudden equipment failures.

Technical Parameters of BENTLY CFP-AI-111

The BENTLY CFP-AI-111 is an analog input module tailored for Condition Monitoring Systems (CMS) of rotating machinery, with parameters optimized for industrial-grade reliability and accuracy:

- Core Module Specifications: 4 independent analog input channels, compatible with mainstream monitoring systems such as Bently Nevada 3500 and 1701, supporting “plug-and-play” cartridge-style installation.

- Sensor Compatibility:

- Passive Sensors: Supports Pt100/Pt1000 Resistance Temperature Detectors (RTDs, temperature range: -200°C to +850°C) and J/K/T/E/R/S/B-type thermocouples (temperature range: -270°C to +1768°C, depending on type).

- Active Sensors: Supports 4–20mA current signals and 0–10V voltage signals (compatible with Bently Nevada 3300 XL vibration sensors, shaft position sensors, pressure sensors, etc.).

- Measurement Accuracy:

- RTD temperature accuracy: ±0.05°C; thermocouple temperature accuracy: ±0.1°C; 4–20mA/0–10V signal accuracy: ±0.02% of Full Scale Range (FSR)—ensuring even tiny changes in critical parameters like vibration and shaft position are accurately captured.

- Sampling Rate: 100 samples per second per channel, enabling real-time recording of pulse-like vibrations caused by rotor imbalance.

- Electrical Performance:

- Power Supply: 24V DC (wide voltage range: 20–30V DC), maximum power consumption: 150mA.

- Protection Design: Input channels feature short-circuit protection (withstands 50V DC) and Electrostatic Discharge (ESD) protection (complies with IEC 61000-4-2 Level 4). Optical isolation (2500V AC for 1 minute) is provided between inputs, data bus, and power supply to isolate external interference.

- Environmental Adaptability:

- Operating Temperature: 0°C to +60°C; Relative Humidity: 5%–95% (no condensation).

- Protection Rating: IP20 (suitable for enclosed cabinet installation); Vibration Resistance: 5Hz (amplitude 0.15mm), meeting operational requirements of power plants, oil and gas platforms, etc.

- Structure & Indicators: Dimensions: 160mm × 100mm × 25mm (fits Bently system cabinets). Each channel is equipped with “Channel Active” and “Channel Fault” LED indicators, with power and communication status displayed simultaneously for quick module status diagnosis.

For more detailed parameters of the BENTLY CFP-AI-111, visit the official link: [BENTLY CFP-AI-111 Product Link](Your provided link will be inserted here).

Advantages and Features of BENTLY CFP-AI-111

Compared with similar analog input modules, the BENTLY CFP-AI-111 offers four core competitive advantages:

- Wide Sensor Compatibility: A single module supports RTDs, thermocouples, 4–20mA, and 0–10V sensors—eliminating the need for separate modules for temperature, vibration, and pressure parameters. This greatly simplifies system architecture and reduces costs. For example, in turbine monitoring, the BENTLY CFP-AI-111 can simultaneously collect bearing temperature (RTD), rotor vibration (4–20mA), and lubricating oil pressure (0–10V) signals, improving data integration efficiency.

- High Measurement Accuracy & Anti-Interference Capability: With a signal accuracy of ±0.02% FSR, it can detect 0.001mm-level shaft position changes to early warn of rotor misalignment faults. The optical isolation design prevents signal interference from on-site strong electromagnetic sources (e.g., motor startup, inverter operation), ensuring data authenticity.

- Excellent System Compatibility: It seamlessly integrates with mature monitoring systems like Bently Nevada 3500 and 1701, requiring no additional driver development. Once connected, the module can directly participate in equipment protection logic (e.g., triggering emergency shutdowns for excessive vibration), shortening project commissioning cycles.

- Comprehensive Self-Diagnosis: The module continuously monitors channel connectivity, sensor status, and its own power supply. In case of issues like cable breaks or sensor failures, it quickly alerts via LED indicators and system alarms—reducing the time for maintenance personnel to troubleshoot and avoiding risks from data loss.

Application Cases of BENTLY CFP-AI-111

With its high reliability and adaptability, the BENTLY CFP-AI-111 is widely used in energy, oil and gas, metallurgy, and other industries dependent on rotating machinery. Typical cases include:

- Turbine Monitoring in Thermal Power Plants: In a 300MW steam turbine generator set, the BENTLY CFP-AI-111 connects 6 vibration sensors (monitoring rotor radial vibration), 4 shaft position sensors (monitoring axial movement), and 8 RTDs (monitoring bearing temperature), transmitting real-time data to the Bently 3500 system. When a bearing temperature abnormally rose to 95°C (threshold: 90°C), the module quickly captured the signal and triggered an alarm, prompting maintenance personnel to shut down the unit in time to avoid bearing burnout.

- Compressor Protection in Oil & Gas Pipelines: On centrifugal compressors in long-distance oil and gas pipelines, the BENTLY CFP-AI-111 collects compressor housing vibration (4–20mA), inlet pressure (0–10V), and motor winding temperature (thermocouple) signals. When pipeline blockage caused a sudden drop in inlet pressure, the module fed the pressure anomaly back to the control system, which automatically adjusted the compressor speed to prevent surge.

- Motor Condition Monitoring in Metallurgical Plants: On roller motors of continuous casting machines in steel mills, the BENTLY CFP-AI-111 uses RTDs to monitor motor stator temperature and vibration sensors to monitor motor bearing vibration. When insufficient lubrication caused the vibration value to exceed 4.5mm/s (threshold: 4mm/s), the module triggered an early warning, allowing maintenance personnel to replenish lubrication promptly and avoid bearing scrapping.

For more application cases of the BENTLY CFP-AI-111, visit the official link: [BENTLY CFP-AI-111 Product Link](Your provided link will be inserted here).

Comparison of BENTLY CFP-AI-111 with Competitors

The BENTLY CFP-AI-111 is compared with common similar modules in the industrial sector (e.g., Emerson CSI 6500 AI Module, SKF Microlog CMXA75) below:

| Comparison Dimension | BENTLY CFP-AI-111 | Emerson CSI 6500 AI Module | SKF Microlog CMXA75 |

|---|---|---|---|

| Measurement Accuracy | ±0.02% FSR (4–20mA/0–10V) | ±0.05% FSR (4–20mA/0–10V) | ±0.03% FSR (4–20mA only) |

| Sensor Compatibility | RTD, Thermocouple, 4–20mA, 0–10V | RTD, 4–20mA | 4–20mA only |

| System Integration | Seamless with Bently 3500/1701; supports protection logic linkage | Requires additional gateway for third-party systems | Only compatible with SKF’s own monitoring platform |

| Anti-Interference Ability | 2500V AC optical isolation | 1500V AC optical isolation | No optical isolation |

The comparison shows the BENTLY CFP-AI-111 has significant advantages in accuracy, sensor compatibility, and system integration—making it ideal for scenarios requiring high monitoring data quality and linked equipment protection (e.g., power plant turbines, oil and gas compressors).

Selection Recommendations and Precautions for BENTLY CFP-AI-111

Selection Recommendations

- Scenario Matching: If you need to monitor multiple types of parameters (temperature, vibration, displacement, pressure) of rotating machinery (turbines, compressors, generators) and integrate with Bently Nevada 3500/1701 systems, the BENTLY CFP-AI-111 is the optimal choice. For single 4–20mA signal acquisition (e.g., ordinary motor vibration monitoring), more cost-effective competitors may be considered.

- Channel Quantity Calculation: A single module has 4 independent channels. When selecting, reserve 1–2 spare channels based on the number of sensors (e.g., 8 sensors require 2–3 BENTLY CFP-AI-111 modules) to avoid re-wiring during later expansion.

- Environmental Adaptation: If the application environment has temperatures below 0°C or above 60°C, additional cabinet heating/cooling devices must be configured to ensure the BENTLY CFP-AI-111 operates within its rated temperature range.

Precautions for Use

- Installation Standards: Strictly follow the BENTLY CFP-AI-111 Installation Manual (available via the product link) for wiring. Ensure correct sensor polarity (especially for thermocouples and active sensors) to avoid module damage due to wiring errors.

- Regular Calibration: Calibrate the module every 12 months using standard signal sources (e.g., high-precision RTD simulators, 4–20mA signal generators) to maintain the ±0.02% FSR measurement accuracy.

- Interference Protection: Use shielded cables for sensor wiring, with the shield grounded at one end (connected to the cabinet ground bar). Avoid parallel routing with power cables to prevent electromagnetic interference from affecting the BENTLY CFP-AI-111’s signal acquisition.

- Troubleshooting: If a channel’s LED indicator shows “Fault,” first check the sensor and cable (e.g., whether the RTD is open, whether the active sensor is powered correctly). Only after eliminating external issues should you check if the module itself is faulty—avoiding unnecessary module replacement.

CFP-AI-111

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922