Description

Product Description

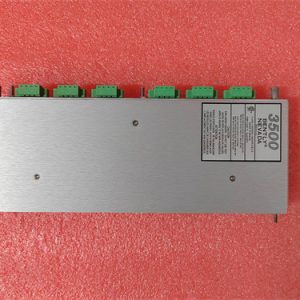

The BENTLY NEVADA 3500/92 136188-01 is a critical communication gateway and system interface module for the 3500 Machinery Protection System. This module acts as the primary data highway between the rack-mounted monitoring modules (such as vibration, speed, and temperature monitors) and external systems, including Distributed Control Systems (DCS), PLCs, plant networks, and dedicated monitoring software like System 1™. The core function of the BENTLY 3500/92 is to collect, consolidate, and translate data from all modules within the 3500 rack into standard industrial protocols for upstream communication. By implementing the BENTLY NEVADA 3500/92 136188-01, operators and engineers gain remote, real-time access to vital machinery health data, alarm statuses, and configuration parameters, enabling centralized monitoring, historical trending, and informed decision-making for predictive maintenance. This gateway is the essential link that transforms a standalone protection system into an integrated component of the plant’s overall operational technology (OT) infrastructure.

Technical Parameters and Features

- Device Type: Communication Gateway / System Interface Module.

- Primary Functions:

- Data Concentration: Polls all modules in the 3500 rack (via the internal backplane) for status, measurements, and alarms.

- Protocol Translation: Converts internal data into multiple industry-standard communication protocols simultaneously.

- Supported Communication Protocols: A key feature of the 3500/92 is its multi-protocol capability. Common protocols include:

- Modbus RTU/TCP: For integration with PLCs and SCADA systems.

- Ethernet Global Data (EGD): A real-time protocol for GE Mark VIe and other control systems.

- OPC (Classic or DA): For connectivity to Windows-based monitoring applications.

- PROFIBUS DP: For integration into Siemens and other PROFIBUS-based networks.

- Physical Interfaces: Typically includes serial ports (RS-232/RS-485) and Ethernet ports (RJ45) to support the various protocols.

- Configuration & Diagnostics: Configured via dedicated software (e.g., 3500 Rack Configuration Software) and provides extensive diagnostic information about its own status and communication health.

- Redundancy Support: Can be configured in redundant pairs (primary/backup) to ensure continuous data availability even if one module fails.

- Key Module Identification: The suffix -01 in 136188-01 indicates a specific firmware version or hardware revision, which is crucial for compatibility.

Advantages and Key Features

- Unified Data Gateway: The BENTLY 3500/92 provides a single, managed point of access for all data from the 3500 rack. This simplifies network architecture and security management compared to having each monitor communicate independently.

- Multi-Protocol Flexibility: Its ability to serve data over several protocols concurrently allows seamless integration into diverse plant environments without requiring additional external gateways or converters.

- Enhanced System Diagnostics: The module itself monitors communication health and rack status, providing valuable diagnostic data that helps distinguish between a machinery problem and a communication/system problem.

- Reliable and Deterministic Data Delivery: Designed for critical applications, it ensures reliable and timely delivery of alarm and trip data to the control system, which is essential for operator awareness and automated safety responses.

- Foundation for Advanced Monitoring: The data stream provided by the BENTLY NEVADA 3500/92 136188-01 is the essential feed for advanced diagnostic software, enabling root cause analysis, waveform viewing, and long-term trend analysis for predictive maintenance.

Application Case Studies in Various Fields

- Combined-Cycle Power Plant: A 3500/92 gateway in a gas turbine protection rack streams vibration, speed, and temperature data via Modbus TCP to the plant DCS for operator display and via a dedicated OPC server to a Condition Monitoring System (CMS) for engineering analysis.

- Oil Refinery: Integrated into the protection system for a critical centrifugal compressor, the BENTLY 3500/92 sends machinery alarms and trips via PROFIBUS DP directly to the safety PLC (SIS), while also sending detailed monitoring data to a central historian for the reliability team.

- Offshore Gas Platform: Used on a compressor module, the gateway communicates using redundant protocols to ensure that vital machinery data reaches the platform’s control room despite harsh environmental conditions and network challenges.

- Hydroelectric Generation: Installed in a governor control panel, the 136188-01 module transmits bearing temperature and vibration data from the hydro-turbine to the plant’s central SCADA system, enabling remote surveillance of the unit’s mechanical condition.

Comparison with Competing Products

Compared to using simple analog and relay outputs from individual monitors or communication modules from other protection system vendors, the BENTLY NEVADA 3500/92 offers a more sophisticated and integrated approach:

- Centralized vs. Distributed Communication: The 3500/92 acts as a centralized gateway for the entire rack. Competing approaches might use individual communication modules per monitor or rely on analog wiring, resulting in a more complex and costly integration.

- Rich Data vs. Basic Signals: While analog outputs provide 4-20mA for a single parameter, the BENTLY 3500/92 transmits a rich dataset including multiple parameters, status bytes, and diagnostic information for each channel, providing much deeper insight.

- Native System Integration: It is an integral, optimized component of the 3500 ecosystem. Third-party gateways or PLCs used to collect data may not fully support all data types or may require complex custom programming to interpret the data correctly.

Selection Advice and Important Notes

- Verify Protocol Requirements: Before selecting the BENTLY 3500/92 136188-01, definitively identify which protocols and which physical interfaces (Ethernet, RS-485) are required by your DCS, PLC, or monitoring network. Order the module with the correct protocol firmware enabled.

- Check Firmware and Revision Compatibility: The -01 revision must be compatible with the other modules in your 3500 rack and the configuration software version. Mixing incompatible revisions can lead to communication failures or loss of functionality.

- Plan for Redundancy: For critical machinery, always configure the communication gateway in a redundant (primary/backup) pair. This ensures data flow is maintained during a module failure, software update, or maintenance event.

- Secure Network Configuration: When connecting the Ethernet port of the 3500/92 to a plant network, assign a static IP address, implement appropriate firewall rules, and follow industrial cybersecurity best practices to protect this critical asset.

- Proper Configuration is Key: The gateway must be meticulously configured within the 3500 framework to map the correct data points from the monitoring modules to the appropriate registers or tags in the external protocol. This requires expertise and careful documentation.

1FK7063-5AF71-1SA0 PLC

CACR-SR05AC2ER PLC

1771-IFM PLC

VARIAN629-5001 PLC

3BSE042238R2PP846 PLC

3BSE003827R1

3BHT300007R1 PLC

3BSE010536R1

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922