Description

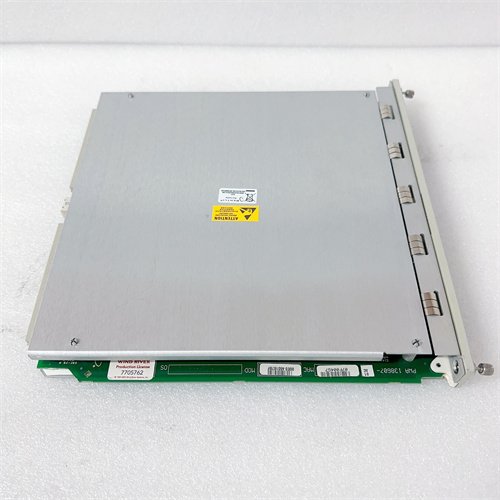

BENTLY 3500/32 125712-01: 4-Channel Proximitor Power Supply Module

Product Description

The BENTLY 3500/32 125712-01 is a critical power supply and signal conditioning module within the Bently Nevada 3500 Machinery Protection System, a premier platform for monitoring the health and safety of rotating machinery. This specific module, often called a “Proximitor Power Supply,” is responsible for powering and interfacing with four eddy-current proximity probes (also known as proximitors). The BENTLY 3500/32 125712-01 provides the precise -24 VDC excitation required by the probes, conditions the raw return signals, and converts them into standardized vibration and position (gap) signals for the monitoring system. Its core function is to serve as the reliable and high-integrity electronic foundation for measuring shaft radial vibration, axial position (thrust), and eccentricity. For engineers responsible for critical turbomachinery, the BENTLY 3500/32 125712-01 is an essential component for accurate and dependable measurement.

Product Parameters

- Product Type: 4-Channel Proximitor / Proximity Probe Power Supply & Conditioner

- Manufacturer Series: Baker Hughes Bently Nevada 3500 System

- Module Designation: 3500/32

- Article Number / Order Code: 125712-01

- Number of Channels: 4 independent channels.

- Input (from Probe): Accepts signals from standard Bently Nevada eddy-current proximity probes (e.g., 5 mm, 8 mm, 11 mm).

- Output Signals per Channel:

- Dynamic (AC) Vibration: A 0 to 10 V peak-to-peak scaled signal (typically 200 mV/mil or 7.87 V/mm).

- Static (DC) Gap/Position: A -2 to -18 VDC signal representing the average gap between the probe tip and the target.

- Probe Power Supply: Provides -24 VDC, 12 mA (typical) excitation per channel to the connected proximity probe.

- Power Requirements: Draws power from the 3500 rack backplane (+5V, ±15V).

- Diagnostics: Extensive onboard diagnostics monitor for probe and cable faults, including开路 (open circuit), short circuit, and invalid gap voltage.

- Configuration: Module type, channel enable/disable, and alarm settings are configured via the 3500 Framework software or directly at the rack.

- Compatibility: Plugs into any monitor slot in a Bently Nevada 3500 rack. Requires a matching 3500/20 Rack Interface Module for communication.

Advantages and Features

- High Channel Density: Four complete probe interfaces in a single slot optimizes rack space for monitoring multi-bearing machinery.

- Integrated Power & Conditioning: Eliminates the need for external power supplies and signal conditioners, simplifying system design, wiring, and maintenance.

- High Reliability & Accuracy: Designed for mission-critical applications, providing stable and precise signal conditioning essential for detecting minute changes in machinery behavior.

- Comprehensive Diagnostics: Continuous monitoring of the health of each probe and its cabling, providing early warning of failures before a loss of protection occurs.

- Standardized Output: Delivers industry-standard 200 mV/mil analog signals, ensuring compatibility with other monitoring equipment and PLC/DCS analog input cards if needed.

- Seamless System Integration: As a native BENTLY 3500/32 125712-01 module, it is fully integrated with the 3500 system, allowing for centralized configuration, alarm management, and communication to plant DCS/PLC systems.

Application Cases in Application Fields

- Gas & Steam Turbines: Powering and conditioning signals from radial vibration probes on turbine and generator bearings, and Keyphasor® probes for speed and phase reference.

- Centrifugal Compressors: Monitoring shaft vibration and axial displacement (thrust position) on critical process compressors in refineries, petrochemical plants, and pipelines.

- Electric Motors & Pumps: Protecting large high-speed motors, boiler feed pumps, and cooling water pumps in power generation and water treatment facilities.

- Hydroturbines & Fans: Monitoring vibration on large vertical turbines and induced/forced draft fans.

- Marine Propulsion: Protecting gearboxes and main thrust bearings on ships.

Comparison with Competing Products

The BENTLY 3500/32 125712-01 competes with similar modules in other machinery protection systems, such as the Emerson (GE) Bently Nevada 3300 XL 8mm system modules or Schenck Vibro VIBROTIP power supplies. Its primary advantage is its position as the standard module within the globally dominant 3500 platform, offering unmatched system integration, support, and a vast installed base. Compared to standalone proximity transducer systems (e.g., the older Bently Nevada 7200 series or AMOT conditioners), the 3500/32 offers digital configuration, advanced diagnostics, and direct integration into a comprehensive protection and monitoring network. For new installations, it is often compared to the newer Bently Nevada Orbit platform, which offers enhanced capabilities but different form factors and system architecture.

Selection Suggestions and Precautions

- System Compatibility: This module is exclusively for use in a Bently Nevada 3500 series rack with a compatible rack interface module (3500/20 or 3500/25). It cannot be used as a standalone device.

- Probe and Cable Compatibility: The entire loop—probe, extension cable, and the BENTLY 3500/32 125712-01—must be electrically matched. The total cable length must be within specified limits (typically 1000 feet/305 meters). Using mismatched components will result in inaccurate readings.

- Gap Voltage Calibration: Proper mechanical installation and electrical “gap setting” are critical. The probe must be physically gapped to the target (e.g., using a micrometer) to achieve the specified “Gap Voltage” (typically between -9 to -11 VDC) as observed in the configuration software. Incorrect gap setting is a leading cause of measurement error.

- Slot Configuration: The module’s slot in the 3500 rack must be correctly configured in the 3500 Framework software to tell the system a 3500/32 module is installed. A mismatch will cause communication faults.

- Diagnostic Response: Configure the system’s response to diagnostics (e.g., alarm on probe fault) appropriately based on the criticality of the measurement.

- Sourcing: Due to its critical role in machinery protection, always source genuine BENTLY 3500/32 modules with the correct article number (125712-01) from authorized Baker Hughes Bently Nevada distributors or reputable, certified spare part suppliers to ensure performance and warranty support. Counterfeit modules pose a severe risk to equipment safety.

3HNA011999-001 PLC

3HNA011784-001 ABB

3HAC17339-1 ABB PLC

ABB 3HAC031936-001 PLC

ABB 3HAC029924-001 PLC

3HAC029924-005 ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922