Description

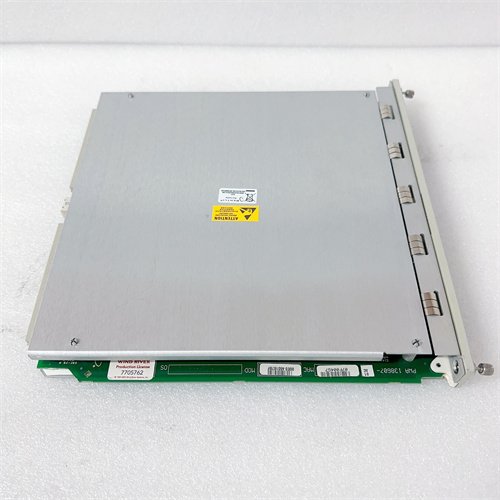

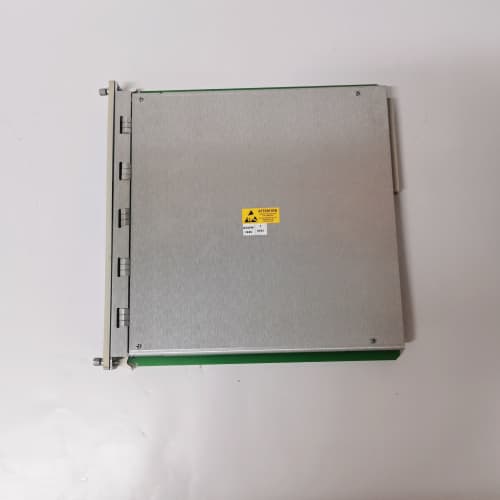

BENTLY 3500/32 125712-01: Velocity Monitor Module for 3500 System

Product Description

The BENTLY 3500/32 125712-01 is a specialized velocity input monitor module for the Bently Nevada 3500 Machinery Protection System. This module is designed to accept input signals from seismic transducers (velocity sensors) that measure casing or structural vibration in machinery. The primary function of the BENTLY 3500/32 125712-01 is to condition, process, and monitor these velocity signals, providing continuous protection by comparing them against user-configurable alarm setpoints (Alert and Danger). It converts the transducer’s AC voltage output into a usable measurement, typically in units of velocity like inches per second (ips) or millimeters per second (mm/s). The reliable operation of this module is critical for detecting excessive vibration that could indicate imbalance, misalignment, or mechanical looseness in pumps, fans, motors, and other rotating or reciprocating equipment.

Product Parameters

- Product Type: Velocity Monitoring Module

- Manufacturer: Bently Nevada (Baker Hughes)

- Part Number: 3500/32 125712-01

- Compatible System: 3500 Series Rack

- Input Type: Accepts signals from velocity transducers (e.g., 100 mV/in/sec).

- Input Channels: Typically 2 or 4 channels per module.

- Frequency Range: Designed to measure vibration within a specific frequency band relevant to machinery health (e.g., 10 Hz to 1 kHz or 2 kHz).

- Dynamic Range: Wide input range to handle varying vibration levels.

- Alarm Setpoints: Independently configurable Alert and Danger (trip) setpoints per channel.

- Outputs: Provides 4-20 mA analog output proportional to vibration level and relay outputs for alarms.

- Diagnostics: Includes channel OK monitoring and fault detection.

Advantages and Features

The key advantage of the BENTLY 3500/32 125712-01 is its dedicated, high-fidelity design for measuring casing vibration, a critical parameter for overall machine health that complements shaft vibration (proximity probe) measurements. It features precise signal conditioning with adjustable filtering to focus on the frequency band of interest, eliminating irrelevant noise. The module provides highly reliable dual-level alarming for both early warning and immediate protection. Its integration within the 3500 system allows for centralized configuration, trending, and diagnostics from a single workstation. The BENTLY 3500/32 125712-01 is built for rugged industrial use and offers excellent noise immunity, ensuring accurate readings in electrically harsh environments.

Application Cases in Various Fields

This module is essential for monitoring equipment where casing vibration is a key indicator. In Power Generation, the BENTLY 3500/32 125712-01 monitors vibration on boiler feed pumps, induced draft fans, and motor bearings. Within Oil & Gas, it protects offshore platform compressors, pipeline pumps, and large cooling tower fans. For Water and Wastewater Treatment, it monitors large vertical turbine pumps and blowers. It is also widely used in HVAC for critical chiller and air handler monitoring, in Mining for crusher and conveyor drive motors, and in General Manufacturing for any high-value motor-driven equipment.

Comparisons with Competing Products

Competing products include velocity monitoring modules from other machinery protection vendors like Emerson (CSI 6500 system) or SKF (Multilog). The BENTLY 3500/32 125712-01 is distinguished by its seamless integration into the industry-standard 3500 platform, which is renowned for its high reliability and comprehensive protection schemes. Compared to using a general-purpose data acquisition system, this dedicated monitor offers pre-engineered protection logic, certified safety ratings (often for API 670 compliance), and simplified integration with plant DCS/PLC systems for shutdown actions. Its value lies in being a proven, application-specific component within a total protection solution.

Selection Suggestions and Precautions

- Transducer Compatibility: Ensure the velocity transducer’s sensitivity (e.g., 100 mV/in/sec) and frequency response are compatible with the BENTLY 3500/32 125712-01 module’s specifications. Using an incorrect transducer will yield inaccurate readings.

- Mounting and Cable Integrity: Velocity sensors must be permanently and securely mounted to the machine casing as per manufacturer instructions. Use high-quality, shielded coaxial cables and secure the connections. Poor mounting or faulty cables are a common source of bad data.

- Alarm Setpoint Rationale: Set Alert and Danger setpoints based on historical baseline data, manufacturer specifications, and industry standards (like ISO 10816). Avoid arbitrary settings. The BENTLY 3500/32 125712-01 should be configured to protect the machine, not cause nuisance trips.

- Regular Calibration and Testing: Implement a schedule for loop verification. This involves using a portable calibrator to inject a known vibration signal into the BENTLY 3500/32 125712-01 channel to verify the reading and the associated alarm relay actions are correct.

- Integration with Shutdown Logic: Understand how the relay outputs from the BENTLY 3500/32 125712-01 are wired into the machinery’s shutdown circuit. When testing or maintaining the module, follow proper procedures to temporarily bypass the trip signal if necessary, using strict management-of-change protocols to avoid an unplanned shutdown.

9905-001

5501-467

9905-017 (PLC)

5464-355 PLC

9902-244 PLC

9905-020 PC

9905-021 DCS

9905-059

9903-226 DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922