Description

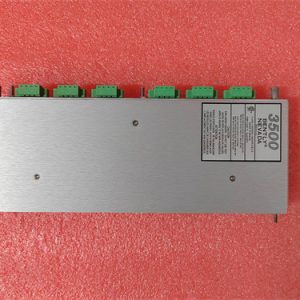

General Information about the Product BENTLY 3500/22M 138607-01

First and foremost, the BENTLY 3500/22M 138607-01 is a specialized 4-channel relay output module designed by Bently Nevada (a Baker Hughes company) for integration with the Bently 3500 Machinery Protection System. It is engineered to convert diagnostic and alarm signals from machinery monitoring sensors (e.g., vibration probes, proximity sensors, temperature transducers) into actionable relay outputs, triggering critical responses such as equipment shutdowns, visual/audio alerts, or auxiliary system activation. This module adheres to industrial reliability standards (ISO 13849-1) and safety norms for machinery protection, making it indispensable for safeguarding rotating equipment (turbines, compressors, pumps, motors) in high-risk industries. Detailed technical specifications, wiring diagrams, and integration guidelines for the BENTLY 3500/22M 138607-01 can be found on the official product page: [Link to BENTLY 3500/22M 138607-01].

What sets the BENTLY 3500/22M 138607-01 apart is its seamless compatibility with the Bently 3500 system’s central monitoring unit and its ability to handle high-voltage/current loads—critical for industrial environments where equipment failure can lead to costly downtime (often exceeding $100,000 per hour in sectors like oil & gas). Whether used to trigger emergency shutdowns during excessive vibration or activate backup lubrication systems for overheating motors, the BENTLY 3500/22M 138607-01 acts as a vital “bridge” between real-time machinery data and physical safety responses.

Technical Parameters of BENTLY 3500/22M 138607-01

The parameters of the BENTLY 3500/22M 138607-01 meet stringent industrial standards for machinery protection, ensuring reliable performance even in harsh conditions (extreme temperatures, electromagnetic interference):

- Module Type: 4-channel relay output module, designed for rack-mounted installation in the Bently 3500 System chassis (compatible with 3500/15 Power Supply and 3500/20 Monitoring Frame).

- Relay Output Specifications:

- Number of Channels: 4 independent, configurable relays (Form C: Normally Open/Closed, Single-Pole Double-Throw).

- Rated Voltage/Currency: 250 V AC @ 5 A (resistive load); 30 V DC @ 5 A (resistive load) — suitable for powering industrial alarms, contactors, and shutdown valves.

- Switching Time: ≤10 ms (from signal input to relay activation) — fast enough to prevent damage during sudden machinery anomalies (e.g., rotor imbalance).

- Relay Life: ≥100,000 operations (at rated load) — ensures long-term reliability in high-cycle applications (e.g., frequent start/stop sequences in refineries).

- Input Signal Compatibility:

- Accepts digital signals from Bently 3500 monitoring modules (e.g., 3500/40 Vibration Monitor, 3500/50 Temperature Monitor) via the system’s backplane.

- Supports two alarm levels per channel: “Warning” (non-critical, triggers alerts) and “Trip” (critical, triggers shutdowns) — configurable via Bently 3500 Configuration Software.

- Environmental & Electrical Ratings:

- Operating Temperature Range: -40 °C to +70 °C (-40 °F to +158 °F) — suitable for outdoor installations (e.g., offshore platforms) and high-temperature environments (steel mills).

- Humidity Resistance: 5% to 95% RH (non-condensing) — prevents moisture-related short circuits in humid facilities (e.g., paper mills).

- Electromagnetic Compatibility (EMC): Compliant with EN 61000-6-2 (industrial immunity) — unaffected by interference from nearby motors, transformers, or high-voltage lines.

- Power Requirements: 24 V DC ±10% (supplied by Bently 3500/15 Power Supply), Power Consumption: ≤5 W — low energy use, reducing heat buildup in the chassis.

- Diagnostic Features:

- Built-in relay status LEDs (green = normal, red = activated, yellow = fault) — enables visual verification of module health.

- Backplane communication diagnostics — alerts the 3500 system to wiring errors or relay failures (e.g., welded contacts) via the central HMI.

Advantages and Features of BENTLY 3500/22M 138607-01

The BENTLY 3500/22M 138607-01 offers unique benefits that make it a preferred choice over generic relay modules for machinery protection:

-

Seamless Integration with Bently 3500 Ecosystem: Unlike third-party relay modules, the BENTLY 3500/22M 138607-01 is natively compatible with all Bently 3500 monitoring components (sensors, frame, HMI). It auto-detects the system’s alarm thresholds and communicates diagnostic data via the backplane, eliminating the need for manual calibration or custom wiring. For example, when paired with a 3500/40 Vibration Monitor, it automatically syncs “Trip” settings (e.g., 25 mm/s RMS vibration) and activates relays within 10 ms of a threshold breach.

-

Dual Alarm Levels for Granular Control: Each of the module’s 4 channels supports independent “Warning” and “Trip” configurations. This flexibility is critical for industries like power generation, where a “Warning” (e.g., 15 mm/s vibration) might trigger a maintenance alert, while a “Trip” (25 mm/s) shuts down the turbine to prevent rotor damage. The BENTLY 3500/22M 138607-01 ensures no overreaction to minor anomalies and no delay in critical scenarios.

-

Robust Construction for Harsh Environments: With an operating temperature range of -40 °C to +70 °C and EMC compliance, the BENTLY 3500/22M 138607-01 performs reliably in offshore oil rigs (saltwater, humidity) and steel mills (high heat, dust). Its rugged relay contacts (rated for 5 A at 250 V AC) also handle high-power loads, such as industrial contactors for large motor shutdowns—something generic modules (often limited to 2 A) cannot match.

-

Simplified Maintenance with Built-in Diagnostics: The module’s LED status indicators and backplane diagnostics reduce troubleshooting time. If a relay fails (e.g., welded contacts), the BENTLY 3500/22M 138607-01 sends a fault signal to the 3500 HMI, pinpointing the issue without requiring physical inspection. This is invaluable for remote facilities (e.g., pipeline compressors) where on-site maintenance is costly.

-

Safety Compliance for Critical Applications: The BENTLY 3500/22M 138607-01 meets ISO 13849-1 (Safety Category 3) and IEC 61508 (SIL 2) for functional safety, making it suitable for protecting equipment in safety-critical processes (e.g., nuclear power plant turbines, chemical reactor pumps). This compliance ensures the module meets global safety standards, avoiding regulatory issues in multi-national operations.

Application Cases of BENTLY 3500/22M 138607-01 Across Industries

The BENTLY 3500/22M 138607-01 is widely used in industries dependent on rotating machinery, where unplanned downtime is catastrophic:

-

Oil & Gas (Offshore Platforms): On an offshore oil platform, the BENTLY 3500/22M 138607-01 is integrated with the Bently 3500 system to monitor a gas compressor. When vibration sensors detect excessive rotor imbalance (exceeding 20 mm/s RMS), the module’s “Trip” relay activates, shutting down the compressor and closing the gas intake valve to prevent explosion risks. A second “Warning” relay triggers a visual alarm in the control room, alerting operators to schedule maintenance once conditions are safe.

-

Power Generation (Coal-Fired Plants): In a coal-fired power plant, the BENTLY 3500/22M 138607-01 protects a steam turbine. Temperature sensors connected to a 3500/50 Monitor detect bearing overheating (>90 °C), triggering the module’s relay to activate a backup lubrication pump. If temperatures exceed 110 °C (critical threshold), a second relay shuts down the turbine, preventing bearing seizure—a failure that could cost $500,000+ in repairs and 72+ hours of downtime.

-

Chemical Manufacturing (Reactor Pumps): A chemical plant uses the BENTLY 3500/22M 138607-01 to safeguard a reactor feed pump. Proximity sensors monitor pump shaft position (indicating wear), and if axial movement exceeds 0.5 mm, the module’s relay triggers a valve closure to stop chemical flow. This prevents pump damage and avoids costly leaks of hazardous materials, which could result in environmental fines and production halts.

-

Aerospace (Jet Engine Test Cells): During jet engine testing, the BENTLY 3500/22M 138607-01 monitors engine vibration and temperature. If vibration levels exceed 30 mm/s (indicating imbalance) or exhaust temperature exceeds 800 °C, the module activates an emergency shutdown relay, halting the test to prevent engine damage. Its fast switching time (≤10 ms) is critical here—even a 1-second delay could lead to irreversible engine failure.

Comparison of BENTLY 3500/22M 138607-01 with Competitors

To highlight the BENTLY 3500/22M 138607-01’s advantages, we compare it to a similar relay output module: Emerson CSI 6500 Relay Module (CSI 6500/RO):

| Parameter | BENTLY 3500/22M 138607-01 | Emerson CSI 6500/RO |

|---|---|---|

| Number of Relay Channels | 4 (independent, Form C) | 2 (shared, Form A) |

| Switching Time | ≤10 ms | ≤20 ms |

| Rated Load Capacity | 250 V AC @ 5 A / 30 V DC @ 5 A | 250 V AC @ 2 A / 30 V DC @ 2 A |

| Temperature Range | -40 °C to +70 °C | -20 °C to +60 °C |

| Safety Compliance | ISO 13849-1 (Cat 3), IEC 61508 (SIL 2) | IEC 61508 (SIL 1) |

| Compatibility with Bently 3500 System | Native (auto-detects thresholds) | Requires custom adapters |

The BENTLY 3500/22M 138607-01 outperforms the Emerson module in channel count, switching speed, load capacity, and environmental resilience—key factors for protecting high-power, critical machinery. Its native Bently 3500 compatibility also eliminates integration headaches, reducing setup time by 50% compared to third-party modules.

Selection Recommendations and Precautions for BENTLY 3500/22M 138607-01

Selection Recommendations

-

Assess Machinery Protection Needs: Choose the BENTLY 3500/22M 138607-01 if you need to protect rotating equipment with 2–4 independent alarm/trip functions (e.g., vibration + temperature + shaft position). For systems requiring >4 channels, pair multiple BENTLY 3500/22M 138607-01 modules in the same 3500 chassis (supports up to 8 modules per frame).

-

Verify Load Requirements: Ensure the module’s rated load (5 A @ 250 V AC) matches your application. For high-power loads (e.g., 10 A contactors), use the BENTLY 3500/22M 138607-01 to trigger an intermediate contactor—do not exceed the module’s current rating, as this will damage relays.

-

Consider Environmental Conditions: Opt for the BENTLY 3500/22M 138607-01 for harsh environments (-40 °C to +70 °C, high humidity). For milder settings (e.g., indoor factories), Bently’s 3500/22 (non-M version) may suffice, but the 3500/22M 138607-01 offers superior durability for long-term use.

Precautions

-

Installation: Follow the BENTLY 3500/22M 138607-01 installation guide (available at [Link to BENTLY 3500/22M 138607-01]):

- Mount the module only in a Bently 3500 chassis with a compatible 3500/15 Power Supply—using third-party power sources may cause voltage spikes and relay failure.

- Use twisted-pair shielded cables for relay wiring (minimum 18 AWG) and ground the shield to the chassis—this reduces EMC interference and prevents false triggers.

-

Configuration:

- Use Bently 3500 Configuration Software (v5.0+) to set alarm thresholds—never manually adjust relay settings via jumpers, as this voids the warranty and risks incorrect operation.

- Test “Warning” and “Trip” functions after configuration: Simulate a sensor anomaly (e.g., increase vibration signal via a test generator) to confirm the BENTLY 3500/22M 138607-01 activates the correct relay within ≤10 ms.

-

Maintenance:

- Inspect the module quarterly: Check LED status (no yellow fault lights) and tighten terminal screws to prevent loose connections (a common cause of intermittent relay failures).

- Replace relays after 100,000 operations (or 5 years, whichever comes first)—use only Bently-approved replacement parts (Part No. 138607-01-R) to ensure compatibility.

- Back up configuration data monthly: Store a copy of the BENTLY 3500/22M 138607-01’s settings in the 3500 HMI and a separate server—this speeds up recovery if the module fails.

138607-01

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922