Description

Product Overview and Description

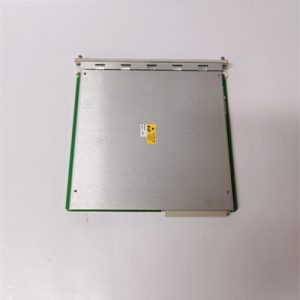

The BENTLY 3500/20 125768-01 is a critical 4-channel Analog Monitor module from the Bently Nevada 3500 Machinery Protection System. This module serves as the primary interface for monitoring the condition of rotating machinery by accepting signals from proximity probes, accelerometers, and other transducers to measure vibration, position, speed, and other dynamic parameters. The BENTLY 3500/20 125768-01 conditions these signals, provides power to the sensors, and generates scaled analog outputs and alarm signals based on user-configured setpoints. It is a fundamental component for predictive maintenance and catastrophic failure prevention in turbomachinery.

Product Parameters

- Module Type: 4-Channel Analog Monitor / Vibration Monitor.

- System: Bently Nevada 3500 Series Rack.

- Channels: 4 independent monitoring channels.

- Input Types: Configurable per channel for:

- Proximitor® input (for eddy-current displacement probes measuring shaft relative vibration and position).

- Seismic input (for accelerometers or velocity transducers measuring casing/bearing absolute vibration).

- Dynamic pressure, temperature, or other process variable (with appropriate signal conditioning).

- Sensor Power: Provides -24 V DC or +18 V DC power to connected transducers (Proximitors, accelerometers).

- Signal Processing: Includes integration (for velocity), filtering, peak-to-peak/true peak detection, and gap voltage monitoring for probes.

- Outputs per Channel:

- Analog Outputs: Two scaled 4-20 mA outputs (e.g., for trend recording).

- Alarm Outputs: Two dedicated alarm relays (Alert and Danger) with user-configurable setpoints and time delays.

- Communications: Integrates with the 3500 rack framework, communicating all data to the 3500/15 TDI (Touchpad Display Interface) and 3500/22M Transient Data Interface for system-wide monitoring.

- Configuration: Programmed via the 3500 Rack Configuration Software connected to the 3500/15 or 3500/22M module.

Advantages and Key Features

- Industry-Standard Protection: The BENTLY 3500/20 125768-01 is the de facto standard in critical machinery protection, offering proven, reliable monitoring for vibrations and other parameters that indicate machine health.

- High Channel Density & Flexibility: Four channels in a single slot allow for comprehensive monitoring (e.g., X and Y vibration on two bearings) while optimizing rack space. Each channel is independently configurable for different sensor types.

- Comprehensive Diagnostics: Continuously monitors the health of the sensor and its own circuitry, providing warnings for probe gap faults, cable opens/shorts, and module failures, enabling predictive maintenance.

- Dual Alarm System: Each channel features independent Alert (warning) and Danger (trip) setpoints with configurable delays, allowing for early operator intervention and automatic machinery shutdown to prevent catastrophic damage.

- Seamless System Integration: As the core monitoring module of the 3500 system, the BENTLY 3500/20 125768-01 seamlessly shares data with other modules in the rack for relay logic, event capture, and system-wide communication to plant DCS/PLC systems.

Application Cases in Various Fields

- Gas & Steam Turbines: Monitoring radial and axial vibration of turbine shafts using proximity probes to detect imbalance, misalignment, or blade loss, with the BENTLY 3500/20 125768-01 providing the primary trip signals.

- Centrifugal Compressors: Protecting critical compressor trains by monitoring shaft displacement relative to bearings (to detect oil whirl/whip) and casing vibration, ensuring operation within safe regions of the performance map.

- Large Electric Motors & Generators: Measuring bearing vibration and shaft runout to detect developing bearing defects or rotor bar issues before they cause an unplanned outage.

- Pumps & Fans: Providing protection for large boiler feed pumps, induced draft fans, or other auxiliary critical equipment in power plants and process industries.

Comparison with Competing Products

The BENTLY 3500/20 competes with machinery protection modules from other specialized vendors like Emerson (CSI 6500 Atlas), Rockwell Automation (Allen-Bradley), and Schenck Trebel. Compared to vibration monitoring functionality embedded within a turbine’s main DCS (like GE’s Mark VIe), the Bently 3500 system is a dedicated, best-in-class protection system with superior signal processing, diagnostics, and a focused safety architecture. Its primary advantage is its unparalleled reputation, extensive installed base, and deep application expertise in the field of machinery diagnostics. For greenfield projects or retrofits where machinery protection is paramount, the BENTLY 3500/20 125768-01 is often the specified choice.

Selection Suggestions and Precautions

- Selection Advice:

- Sensor Compatibility: Match the module’s input type and electrical requirements (e.g., -24V DC for standard Bently Proximitors) precisely with the sensors installed on the machine.

- Monitoring Strategy: Plan channel allocation based on API or OEM guidelines (e.g., X and Y probes per bearing, axial position). Ensure you have enough channels for all required monitoring points.

- System Framework: This module requires a 3500 series rack, power supply, and a communication interface (like a 3500/15 TDI) to form a complete system. It is not a stand-alone device.

- Important Precautions:

- Critical Safety Function: This module is often part of a Safety Instrumented System (SIS). Any modification, configuration, or bypass must follow strict management of change (MOC) and safety procedures.

- Proper Grounding & Shielding: Sensor cabling must use double-shielded cable with the shield properly terminated (usually at the rack end only) to prevent ground loops and ensure signal integrity.

- Configuration Backup: Always maintain a secure, up-to-date backup of the module’s configuration. Loss of configuration requires recalibration and re-validation of alarm setpoints.

- Bypass Procedures: Never mechanically bypass or jumper the trip relays without following a formal operational bypass procedure. Unauthorized bypass can leave machinery unprotected.

- Calibration & Testing: Setpoints must be configured based on machine OEM guidelines and operational history. Regularly test the monitoring loop using a calibration oscillator or TSI tester to verify the entire chain from sensor to trip relay.

- Genuine Components: Use only genuine Bently Nevada sensors, cables, and modules like the BENTLY 3500/20 125768-01 to ensure system performance and warranty. Incompatible components can affect readings and safety functions.

1C31113G04 EMERSON

1C31113G05 PLC

1C31113G06 PLC EMERSON

1C31116G01 EMERSON

1C31116G02 PLC EMERSON

1C31116G03 PLC EMERSON

1C31125G01 PLC EMERSON

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922