Description

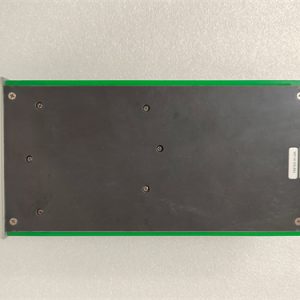

BENTLY 3500/05-01-03-00-00-00 – Product Overview

Product Description

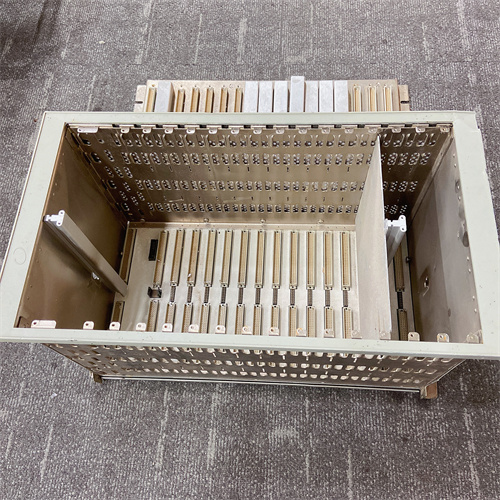

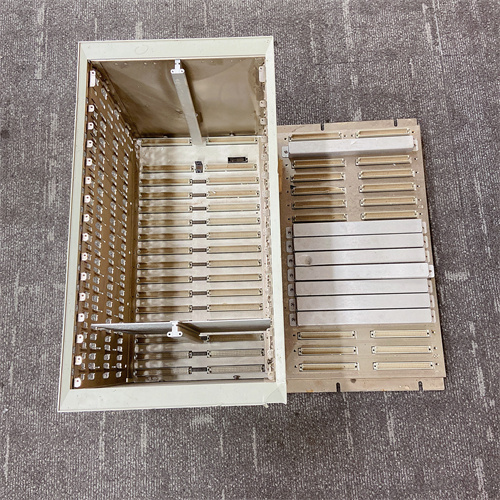

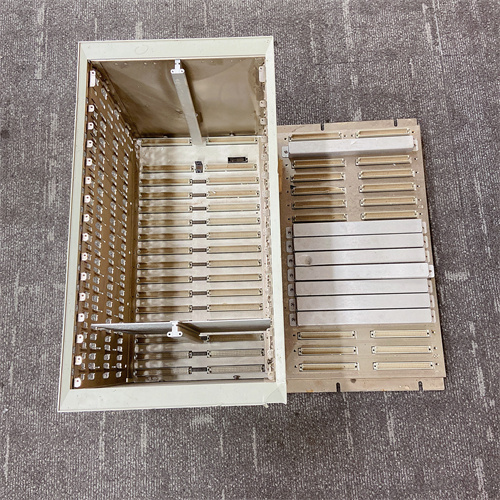

The BENTLY 3500/05-01-03-00-00-00 is not a PLC or DCS module, but a critical system component within the Bently Nevada 3500 Machinery Protection System. This specific part is the 3500/05 Keyphasor Module, a vital sensor interface for rotating machinery monitoring. The primary function of the BENTLY 3500/05-01-03-00-00-00</a> is to process the signal from a Keyphasor transducer, which provides a once-per-revolution timing pulse. This pulse is the fundamental reference for all vibration phase measurements, speed calculation, and event ordering within the 3500 rack. Without a properly configured BENTLY 3500/05-01-03-00-00-00, the system cannot determine the angular position of a rotor, rendering phase-sensitive diagnostics like imbalance and misalignment analysis impossible. The reliability and accuracy of this specific configuration of the Keyphasor Module are therefore non-negotiable for predictive maintenance programs.

Product Parameters

- Full Part Number: 3500/05-01-03-00-00-00

- Product Family: Bently Nevada 3500 Series

- Module Type: 3500/05 Keyphasor Module

- Configuration Code: 01-03-00-00-00 (This defines specific hardware/software revisions and factory configurations).

- Input Channels: Typically one or two independent Keyphasor input channels.

- Input Type: Accepts signals from proximity probes (Eddy current sensors), magnetic pickups, or optical sensors.

- Function: Provides a digital Keyphasor pulse, speed (RPM) value, and a speed indication for the Machinery Protection System and connected monitoring software.

- Outputs: Keyphasor pulse to other 3500 monitor modules (vibration, position).

Advantages and Features

- Critical for Diagnostics: Enables phase measurement, which is essential for identifying the root cause of vibration issues (e.g., imbalance at 1x running speed, misalignment at 2x).

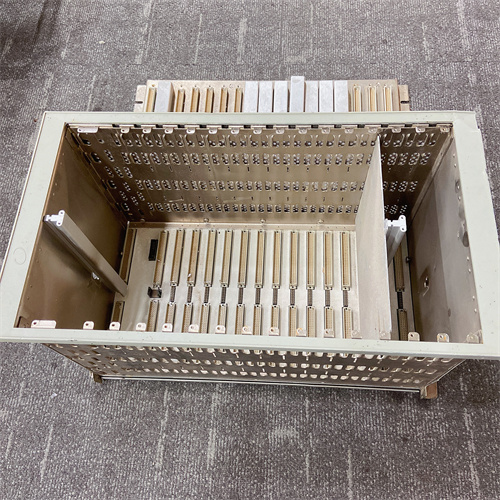

- High Reliability & Redundancy: Designed for continuous, fault-tolerant operation in critical machinery environments. Systems often employ dual 3500/05 modules for redundancy.

- Advanced Signal Processing: Includes adjustable input sensitivity, filtering, and validation to ensure a clean, reliable Keyphasor signal even in electrically noisy environments.

- Seamless System Integration: Fully integrated within the 3500 rack, communicating directly with vibration, position, and temperature monitors to provide them with synchronized phase data.

- Comprehensive Diagnostics: Continuously monitors the health of the connected Keyphasor transducer and its own circuitry, providing alerts for sensor faults or signal loss.

Application Cases in Application Fields

The BENTLY 3500/05-01-03-00-00-00 is indispensable in industries where large, expensive rotating machinery is the core of the process:

- Oil & Gas: On critical turbomachinery such as gas turbines, centrifugal compressors, and steam turbines on offshore platforms and in refineries to enable condition monitoring and protect against catastrophic failure.

- Power Generation: For protecting boiler feed pumps, induced/forced draft fans, and most importantly, the main generator turbine sets in coal, gas, and nuclear power plants.

- Petrochemical & Chemical: Monitoring large reactor feed compressors and synthesis gas compressors, where unplanned downtime results in massive production losses.

Comparisons with Competing Products

- vs. General PLC High-Speed Counter Cards: A PLC card can count pulses for speed but lacks the specialized conditioning, validation, and tight integration with vibration analysis hardware and software that the dedicated BENTLY 3500/05 provides. The 3500 system is a purpose-built protection system, not just a measurement device.

- vs. Other Machinery Protection Systems (e.g., Emerson/GE Bently Nevada’s own older 3300 system): The 3500/05-01-03-00-00-00 is part of the modern, modular, and software-configured 3500 platform, offering greater flexibility, enhanced diagnostics, and better communication capabilities (e.g., Ethernet) compared to its hardwired predecessors.

- vs. Simplified Vibration Monitors: Many basic vibration switches or monitors have built-in speed input. The BENTLY 3500/05 is part of a comprehensive, multi-channel system where the Keyphasor signal is shared with multiple monitor modules simultaneously, providing a unified phase reference for the entire machine train.

Selection Suggestions and Precautions

- Selection Suggestion: The specific configuration 3500/05-01-03-00-00-00 must be selected based on the existing 3500 rack configuration and compatibility with other modules. It is not a standalone item but a part of a system. Always verify the exact part number against the system’s master database or configuration manual.

- Precautions:

- Configuration is Critical: The module’s software configuration (jumper settings or software-based in later revisions) for input type (proximitor vs. magnetic), sensitivity, and filtering must match the installed sensor. Incorrect configuration will lead to faulty or missing Keyphasor signals.

- Sensor Installation & Gap: The health of the Keyphasor signal depends entirely on proper transducer installation. The gap between the proximity probe tip and the Keyphasor key (or gear tooth) must be set precisely according to the probe’s specifications.

- Not a General-Purpose Module: The BENTLY 3500/05 is exclusively for Keyphasor duty. It cannot be used for general analog or digital I/O.

- System Expertise Required: Installation, configuration, and troubleshooting of this module require specific training on the Bently Nevada 3500 system. It is not a plug-and-play component for standard automation engineers without specialized knowledge.

5STP04D4200 PLC

5STP06D2800

5STP08F6500 PLC

5STP10D2303 PLC

5STP12F4200 PLC

5STP16F2200 PLC

5STP16F2800

5STP16F2801 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922