Description

Product Overview and Introduction

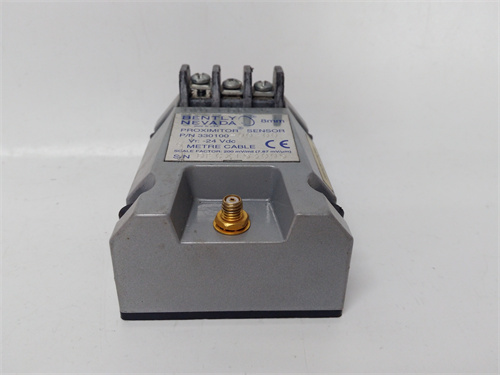

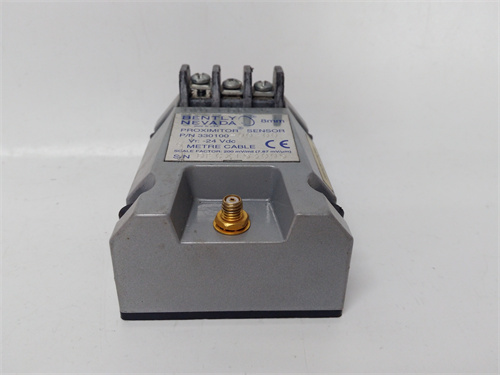

The BENTLY 330100-90-00 is a fundamental and critical component within Bently Nevada’s condition monitoring ecosystem: a standard 8 mm diameter eddy-current proximity probe transducer system. This specific part number, BENTLY 330100-90-00, typically refers to a complete proximity transducer assembly, which includes the probe, extension cable, and a Proximitor® driver (signal conditioner). This system is the industry-standard sensor for measuring relative vibration (shaft displacement), axial position (thrust), speed (RPM), and phase (Keyphasor®) on rotating machinery such as turbines, compressors, and large pumps.

Detailed Product Parameters and Specifications

The performance of this transducer system is defined by precise mechanical and electrical specifications:

- Component Set: A complete system including:

- Probe: An 8 mm diameter, cased eddy-current proximity probe with a standard length (e.g., 60mm, 80mm). It contains a sensing coil.

- Extension Cable: A double-shielded, insulated cable of a specified length (e.g., 5m, 10m) to connect the probe to the proximitor.

- Proximitor: The signal conditioning module that provides a high-frequency radio frequency (RF) signal to the probe, conditions the returning signal, and outputs a DC voltage proportional to the gap between the probe tip and the observed metallic surface (the target).

- Electrical Output: The Proximitor provides two key outputs:

- Analog Gap Voltage: A -24 V DC to -2 V DC (typical) signal where the voltage is linearly proportional to the gap between the probe tip and the target. This is the primary measurement for displacement and position.

- Dynamic AC Signal: The AC component superimposed on the gap voltage, representing the vibration waveform.

- Sensitivity: Standard sensitivity is 200 mV/mil (7.87 V/mm). This means a 1 mil (0.001 inch) change in gap results in a 200 mV change in output.

- Linear Range: The range over which the output voltage is linear to the gap, typically from 10 to 90 mils (0.25 to 2.3 mm) for an 8 mm probe.

- Target Material: Requires a ferromagnetic target (typically mild steel) for optimal performance. Calibration is specific to the target material.

- Temperature Rating: The probe is rated for continuous operation at high temperatures, often up to 120°C (248°F) or higher, with optional high-temperature versions available.

Key Advantages and Distinctive Features

The BENTLY 330100-90-00 system delivers unparalleled reliability and performance for machinery diagnostics:

- Industry Standard Accuracy and Reliability: Bently Nevada’s proximity transducer systems set the global benchmark for accuracy, linearity, and long-term stability in vibration measurement, forming the trusted basis for machinery protection.

- Direct Measurement of Shaft Relative Motion: Unlike casing-mounted sensors, it measures the shaft’s motion relative to the bearing housing, which is the most direct indicator of bearing condition and dynamic rotor behavior.

- Robust Construction for Harsh Environments: The probe is built to withstand extreme temperatures, pressure, and the corrosive atmospheres found in turbines and compressors. The cable is double-shielded for superior noise immunity.

- Integrated System Compatibility: As a genuine Bently Nevada component, the 330100-90-00 guarantees perfect electrical and mechanical compatibility with Bently Nevada monitoring systems (e.g., 3500 series racks, ADRE systems), ensuring calibrated performance.

- Comprehensive Diagnostic Data: It provides not just a vibration amplitude (via the dynamic signal) but also the absolute position of the shaft within the bearing clearance (via the gap DC voltage), offering two critical parameters for machinery health assessment.

Application Scenarios and Case Studies

This transducer system is indispensable for protecting and monitoring high-value rotating assets:

- Steam & Gas Turbines: Measuring radial vibration on turbine shafts, axial position of the rotor (thrust bearing wear), and providing a Keyphasor® signal for balancing and analysis.

- Centrifugal & Axial Compressors: Monitoring shaft vibration to detect unbalance, misalignment, and oil whirl/whip instabilities in critical process compressors.

- Hydroelectric Generators: Measuring shaft runout and vibration on large vertical hydro units.

- Large Motor & Pump Trains: Protecting motors and pumps in critical services like boiler feed water or reactor coolant.

A classic application case is on a synthesis gas compressor in an ammonia plant. A set of BENTLY 330100-90-00 probes, installed at each bearing, provides continuous vibration and position data to a Bently Nevada 3500 monitoring system. A sudden increase in vibration at 1X running speed detected by these probes alerted operators to developing rotor unbalance, allowing for a planned shutdown and rebalancing before a catastrophic failure occurred.

Comparison with Competing Products

Compared to proximity probe systems from other manufacturers like SKF (Microlog), Emerson (CSI), or Metrix, the BENTLY 330100-90-00 is the recognized premium benchmark:

- Gold Standard Performance: It is often specified as the required sensor in API (American Petroleum Institute) standards for machinery protection. Its performance specifications, particularly linearity and temperature stability, are considered top-tier.

- System-Wide Calibration Guarantee: When used with Bently Nevada monitors, the entire loop (probe, cable, proximitor, monitor) is calibrated as a system, ensuring absolute measurement accuracy. Mixing brands can introduce calibration errors.

- Global Recognition and Support: The Bently Nevada name carries unmatched weight in the machinery diagnostics field, backed by the largest network of specialist application engineers.

Competitors may offer lower-cost alternatives or different form factors, but for the most critical, high-speed machinery where measurement integrity is non-negotiable, the Bently Nevada system, starting with the 330100-90-00, is the predominant choice.

Selection Guidelines and Important Considerations

Proper selection, installation, and maintenance of this transducer are critical for accurate data:

- Verify Complete Kit Contents: Ensure the part number 330100-90-00 includes all required components (probe, cable, proximitor) for your specific length and connector requirements.

- Critical Gap Setting (Air Gap): The probe must be installed at the correct mechanical gap within its linear range (typically the midpoint, e.g., 50 mils). An incorrect gap will lead to inaccurate or non-linear readings.

- Target Material and Surface Finish: The target area on the shaft must be made of the correct material (mild steel) and have a smooth, clean, and concentric surface. A poor target will distort the signal.

- Cable Routing and Connection: Route the extension cable away from power cables to avoid electrical noise. Ensure all connectors (probe-to-cable, cable-to-proximitor) are clean, tight, and environmentally sealed if necessary.

- Calibration and System Integrity: The entire transducer system should be bench-checked for proper Gap Voltage and sensitivity before installation. Never mix probes, cables, or proximitors from different kits or manufacturers without verifying system calibration.

- Safety and Installation: Installation often requires machinery disassembly. Follow all lock-out/tag-out procedures. Use proper tools to avoid damaging the probe tip. For all installation and calibration procedures, always consult the official Bently Nevada manual for the 330100-90-00, available via the product link. Regularly check the gap voltage during operation to monitor for probe deterioration or target surface issues.

IC697PWR720 PLC

HPN-14A-05-J8XA-BB3 PLC

CP-20A-5-J601A-SP PLC

PCD235A101 PLC

1SAJ924007R0001 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922