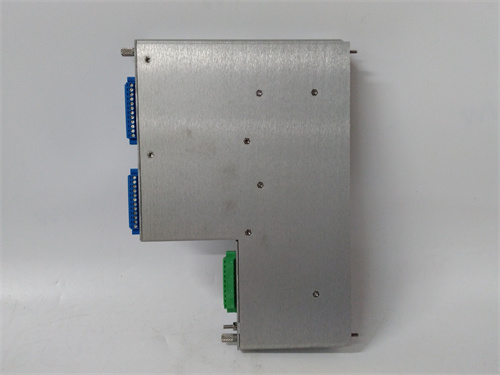

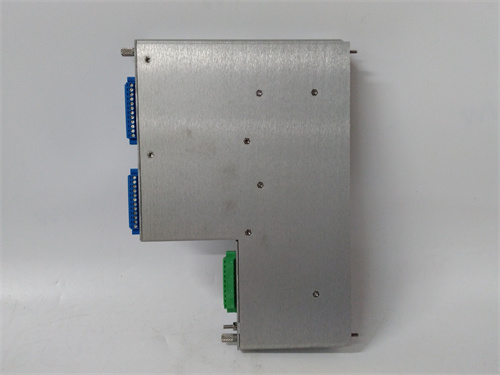

Description

Product Overview

The BENTLY 135489-02 is a critical monitoring module within the Bently Nevada 3500 machinery protection system, functioning as a Dual-Channel Proximity Probe Monitor. This module is designed to process signals from two independent eddy current proximity probes to monitor shaft radial vibration or axial position (thrust). Its primary role is to condition the DC gap voltage signals from two proximitors, compute vibration amplitude (peak-to-peak displacement in mils or microns) and position (DC gap in mils or mm), compare these values to user-configured alarm setpoints, and communicate all data and status to the 3500 rack. For comprehensive technical documentation, configuration guides, and wiring diagrams, please refer to the official product resource: BENTLY 135489-02. The BENTLY 135489-02 is a fundamental component for protecting high-speed rotating machinery like turbines and compressors, where precise measurement of shaft dynamics is essential for safe operation.

Product Parameters and Specifications

- Function: Dual-Channel Radial Vibration / Axial Position Monitor for 3500 System.

- Input Type: Accepts the conditioned -2 to -18 V DC gap voltage signals from two independent proximitors (e.g., Bently Nevada 3300 XL Proximitor System).

- Measurements Per Channel:

- Dynamic Vibration (AC): Computes peak-to-peak displacement (µm pk-pk or mils pk-pk) by analyzing the AC component of the gap voltage.

- Static Position (DC): Measures the average DC gap voltage, representing the steady-state position of the shaft within the probe’s range.

- Gap Voltage: Provides a direct readout of the raw DC bias for diagnostic purposes.

- Alarm Channels: Each of the two monitor channels provides fully independent, configurable Alert and Danger alarm setpoints for both the dynamic (vibration) and static (position) measurements, with adjustable time delays.

- Outputs:

- 4-20 mA Analog Outputs: Separate outputs for each channel’s dynamic vibration and static position.

- Relay Outputs: Dedicated relay contacts for each alarm (Dynamic Alert, Dynamic Danger, Static Alert, Static Danger per channel).

- Buffered Sensor Outputs: Replicated gap voltage signals for external analysis.

- Configuration: Configured via the 3500 rack’s Frame Interface Module using dedicated software. Settings include probe sensitivity, alarm values, filter settings (high-pass for vibration), and alarm delays.

- Diagnostics: Monitors for Sensor Fault conditions (e.g., broken wire, short circuit, invalid gap voltage) on each channel.

Advantages and Key Features

The BENTLY 135489-02 offers distinct advantages for high-reliability shaft monitoring. Its dual-channel design in a single slot provides efficient rack space utilization for monitoring X and Y axes on a single bearing. The module delivers comprehensive measurement, providing both dynamic vibration (for condition) and static position (for alignment and load) data simultaneously. Its sophisticated alarm logic with independent dynamic and static setpoints allows for precise machine protection, such as tripping on excessive vibration while alerting on a gradual shift in shaft position. Seamless integration within the 3500 system enables it to share data with other modules (e.g., a tachometer module for phase reference) for advanced diagnostics like orbit plots. The BENTLY 135489-02 is engineered for maximum reliability and failsafe operation, with diagnostics designed to trigger an alarm rather than a false safe reading in case of sensor failure.

Application Cases in Industry

This module is the workhorse for shaft monitoring on critical high-speed equipment. In Gas and Steam Turbines for power generation, 135489-02 modules monitor radial vibration at each journal bearing. On Centrifugal and Axial Compressors in oil & gas and chemical plants, they monitor vibration and axial thrust position. For Hydroelectric Turbines and Large Motor/Generator sets, they provide essential shaft dynamics data. The BENTLY 135489-02 is also critical on Process Gas Turbines, Pump Trains, and Marine Propulsion gearboxes. It is used wherever API 670 standards for machinery protection are applied.

Comparison with Competing Products

- vs. Velocity Monitor Modules (e.g., 135473-01): Velocity monitors measure casing vibration. The 135489-02 measures shaft-relative vibration and position, which is necessary for understanding rotor dynamics and is the primary protection method for fluid-film bearing machines.

- vs. Single-Channel Proximity Monitors: The dual-channel 135489-02 provides two fully independent monitor channels in one module slot, offering better density and often more features (like dedicated static position alarms) than two separate single-channel units.

- vs. Other Vibration Monitor Brands (e.g., Emerson CSI, SKF): Competing systems have similar dual-proximitor monitor cards. The BENTLY 135489-02 differentiates itself through its deep integration with the pervasive 3500 platform, compliance with API 670, and the extensive global service infrastructure of Bently Nevada. The configuration software and interoperability with other 3500 modules are key strengths.

Selection Suggestions and Precautions

- Selection Advice:

- Probe/Proximitor System Matching: The BENTLY 135489-02 must be used with a compatible Bently Nevada proximitor system (e.g., 3300 XL). The probe sensitivity (mV/mil) must be accurately entered into the module’s configuration.

- Measurement Orientation: Typically, the two channels are used for X and Y axes on a single bearing, mounted 90 degrees apart (e.g., 45° left/right of vertical). Configure the software accordingly for proper vector display.

- Alarm Setting Philosophy: Set dynamic (vibration) alarms based on historical baseline data, manufacturer limits, or standards like API 670. Set static (position) alarms based on allowable shaft float or thrust bearing clearance.

- Redundancy Considerations: For ultra-critical applications, redundant probes on the same axis may be monitored by separate 135489-02 modules (or separate channels in a quadruple module) for voting logic.

- Important Precautions:

- Probe Installation and Gap Setting: The accuracy of the 135489-02 depends entirely on proper probe installation. The gap must be set correctly (typically to achieve -10 V DC bias), and the target area must be clean and machined.

- Cable and Connector Integrity: Use only specified coaxial cables. Ensure all BNC or other connectors are clean and tight. Intermittent connections are a common source of erratic readings and faults.

- Gap Voltage Verification: During commissioning and troubleshooting, always check the DC gap voltage. A value outside the expected range (e.g., -8 to -12 V DC) indicates an installation problem, a faulty probe, or incorrect power to the proximitor.

- Bypass During Rotation: When rotating the shaft for maintenance (e.g., during alignment), the large, slow vibration signal can trigger alarms. Use the proper bypass function via the software or the rack interface module, following strict procedures.

Bently 3500/45-01-00-1 PLC

Bently 3500/42-01-00-1 PLC

parker pa05s-133

XVME-500/4 PLC

TVD1.3-15-03 PLC

MKD071B-035-KG0-KN PLC

6DP1230-8CC PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922