Description

Product Description

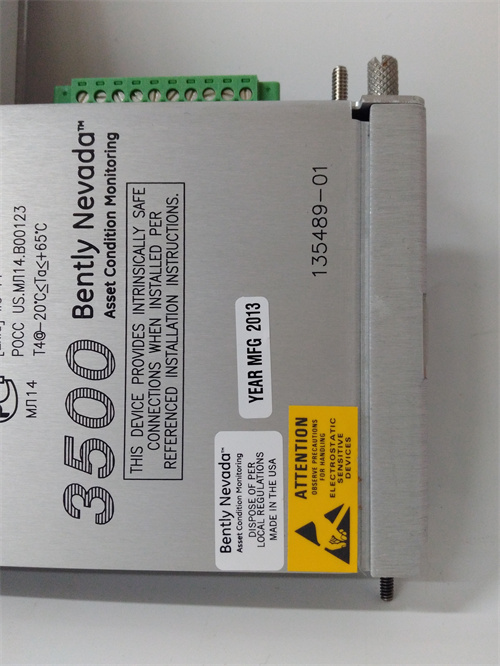

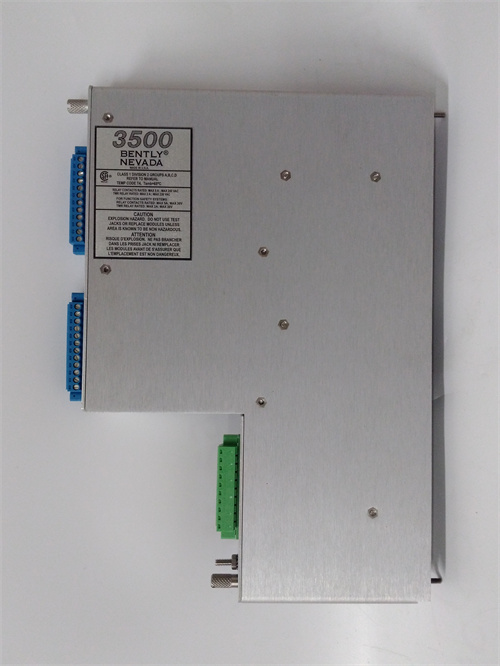

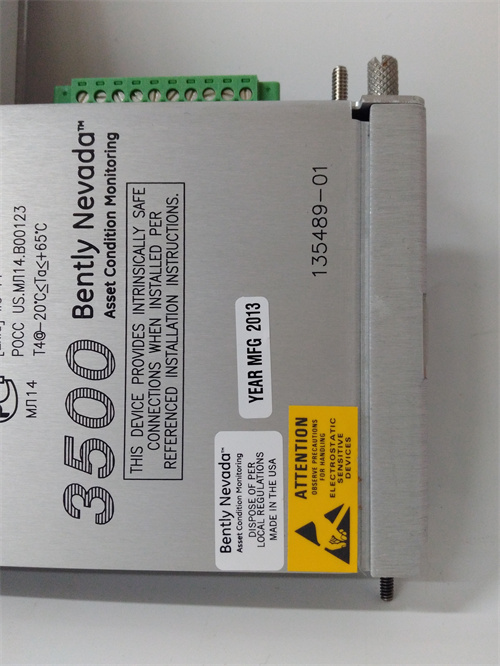

The BENTLY 135489-01 is a critical communication and system interface module for the Bently Nevada (Baker Hughes) 3500 series machinery monitoring system. This module, often a Gateway or Communication Interface unit, serves as the primary data bridge between the 3500 monitoring rack and external systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), asset management software, or engineering workstations. The BENTLY 135489-01 is responsible for collecting, packaging, and transmitting machinery health data—including vibration, temperature, position, and status information—from all other modules in the 3500 rack via a standard industrial protocol. For comprehensive technical specifications, configuration manuals, and protocol guides, the essential resource is the official Baker Hughes Bently Nevada documentation portal for the BENTLY 135489-01. Implementing the 135489-01 module is essential for integrating real-time machinery protection and condition monitoring data into plant-wide control and information systems. Its function transforms a standalone protection rack into a node in a networked predictive maintenance strategy.

Product Parameters

- Manufacturer / Brand: Bently Nevada (Baker Hughes).

- Series: 3500 Machinery Monitoring System.

- Model / Part Number: 135489-01 (System Gateway / Communication Interface).

- Function: Protocol Gateway or Communication Interface Module.

- Primary Role: Transmits data from the 3500 backplane to an external network. Common protocol support includes:

- Modbus RTU (RS-232/485)

- Modbus TCP/IP (Ethernet)

- OPC (Classic or DA)

- Profibus DP

- EtherNet/IP

- Data Access: Provides access to real-time values (process variables), alarm/alert statuses, module configuration, and diagnostic information from all monitors in the rack.

- Configuration: Configured via dedicated software (e.g., 3500 Configuration Software) to set the network parameters (IP address, baud rate, node ID) and define the data map (register mapping for Modbus).

- Power: Powered from the 3500 system backplane.

- Network Ports: Includes physical ports appropriate for its protocol (e.g., RJ-45 for Ethernet, terminal blocks or D-sub for serial).

- Form Factor: A single-slot or multi-slot module designed for installation in a 3500 series rack.

- Compatibility: Designed to work with all standard 3500 series monitor modules (vibration, position, temperature, etc.).

Advantages and Features

- Seamless System Integration: Enables the critical flow of machinery health data into plant control rooms and maintenance systems, allowing for centralized monitoring and coordinated responses to alarms.

- Protocol Flexibility: Supports major industrial protocols, allowing integration with control systems from Siemens, Rockwell, ABB, Emerson, and others, providing significant design flexibility.

- Centralized Data Access: Consolidates data from up to 32 monitoring channels (depending on rack configuration) into a single communication stream, simplifying network architecture.

- Enhanced Diagnostics: Allows remote access to module health and diagnostic data, facilitating troubleshooting and reducing the need for physical presence at the rack.

- Foundation for Predictive Maintenance: By making vibration and process data available to asset management software (like System 1®), the BENTLY 135489-01 is a key enabler for advanced analytics and predictive maintenance programs.

Application Cases in Industry

- Power Plant DCS Integration: The BENTLY 135489-01 (configured for Modbus TCP/IP) connects a 3500 rack monitoring a gas turbine to the plant’s Emerson Ovation or Siemens SPPA-T3000 DCS, allowing operators to view vibration trends and alarms directly on their process graphics.

- Refinery Compressor Monitoring: A module configured for Profibus DP integrates vibration data from a critical centrifugal compressor train into a Siemens PCS 7 system, enabling automatic unit load shed based on vibration levels.

- Pipeline Station SCADA: Provides Modbus RTU serial communication to a regional SCADA system, transmitting pump and turbine health data from remote compressor stations for centralized surveillance.

- Asset Performance Management: Streams data via OPC to software like Bently Nevada’s System 1® or other APM platforms, where algorithms analyze trends to predict bearing failures or imbalance issues weeks in advance.

- Hydroelectric Plant PLC Network: Integrates with a plant’s Rockwell ControlLogix network via EtherNet/IP, providing generator vibration and speed data for unit protection logic.

Comparison with Competing Products

Competing products are communication gateways from other monitoring system vendors, such as the EPRO (now Baker Hughes) MMS 6850 Ethernet Gateway or Schenck Vibroconcept VC-4000 gateway. The BENTLY 135489-01 differentiates itself through its native, high-fidelity integration with the market-leading 3500 platform. Compared to a generic protocol converter, it is purpose-built to understand the 3500 data structure, ensuring reliable and efficient data transmission with all channel parameters intact. Its primary advantage is the assurance of compatibility, performance, and manufacturer support within the comprehensive Bently Nevada ecosystem, which is critical for maintaining the integrity of safety-related machinery protection data.

Selection Suggestions and Precautions

- Selection Suggestions:

- Select the BENTLY 135489-01 based on the specific industrial network protocol required by the host system (DCS, PLC, SCADA). Ensure the module variant matches (e.g., Modbus TCP vs. Profibus).

- Verify the firmware version of the 135489-01 is compatible with the version of the 3500 rack firmware and the host system’s requirements.

- Plan the data mapping carefully. Determine which parameters (e.g., overall vibration, gap voltage, 1X amplitude) from which channels need to be transmitted to the host system to avoid network overload.

- Precautions:

- Network Configuration: The module’s network settings (IP address, subnet, gateway for Ethernet; node ID and baud rate for serial) must be meticulously configured and must not conflict with other devices on the network.

- Data Mapping Complexity: Configuring the register map (for Modbus) or tag database (for Ethernet/IP) is complex and must be done accurately. The map in the host system must exactly match the source map in the 135489-01. Errors will result in corrupt data.

- Cyclic vs. On-Demand Data: Understand the communication model. Some protocols are polled (the host asks for data), others can publish. Configure scan rates appropriately to balance data freshness with network load.

- Security: For Ethernet-connected modules, implement appropriate network security measures (firewalls, VLANs) as recommended by Baker Hughes. An unprotected gateway can be a network vulnerability.

- Genuine Parts and Expert Configuration: Source the BENTLY 135489-01 from authorized distributors. Configuration is non-trivial and should be performed by personnel trained on the 3500 software. Always back up the rack configuration before making changes. Test the communication link thoroughly before placing the system into service.

4351B CPU

1326AB-B520F-M2L PLC

65ba030exkto

5136-PFB-VME CPU

AIRDRV 4S017-841 PLC

WR-D4004 PLC

Mitsubishi MR-J3-22KB IEC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922 Wechat:+86 15343416922

Wechat:+86 15343416922