Description

Product Overview

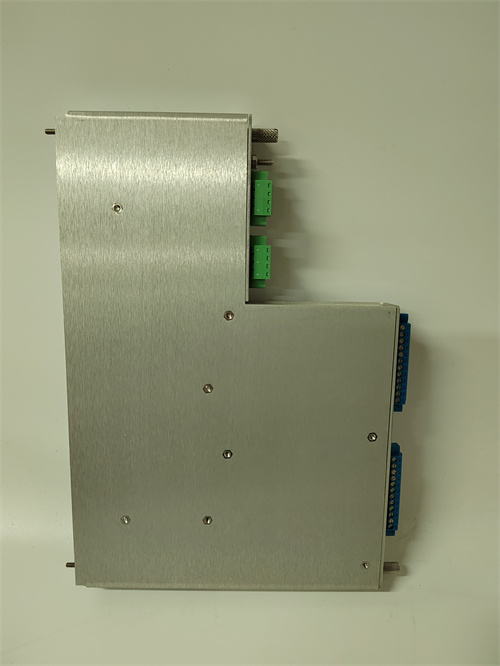

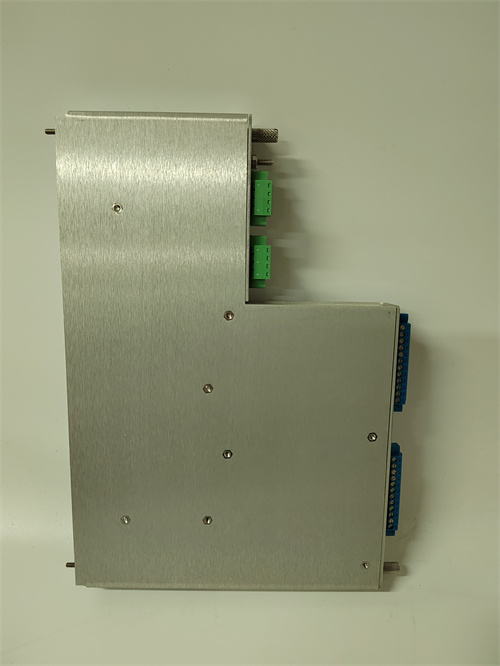

The BENTLY 135473-01 is a specialized monitoring module within the Bently Nevada 3500 machinery protection system, functioning specifically as a Velocity Input Monitor. This module is engineered to process signals from velocity transducers (seismic sensors) that measure the absolute vibration of a machine’s casing or structure. Its primary role is to condition the incoming AC signal, calculate the overall vibration amplitude (in velocity units such as mm/s or in/s), compare it to user-defined alarm setpoints, and relay status and data to the 3500 system for display, recording, and protective action. For detailed technical manuals, configuration guides, and wiring schematics, please visit the official product resource: BENTLY 135473-01. The BENTLY 135473-01 is a critical component for safeguarding a wide range of industrial rotating equipment where structural vibration is a key health indicator, providing both monitoring and protection functions.

Product Parameters and Specifications

- Function: Velocity Vibration Monitor Module for the 3500 Rack.

- Input Type: Accepts signals from piezoelectric velocity transducers, which generate an AC voltage output proportional to vibration velocity.

- Signal Conditioning: Features include programmable gain, bandpass filtering (configurable high-pass and low-pass filters) to isolate the vibration frequency band of interest, and signal integration/differentiation options.

- Measurement: Computes the overall vibration amplitude, typically reported as a peak or root-mean-square (RMS) value within the configured frequency band.

- Alarm Channels: Provides multiple, independently configurable alarm levels (commonly Alert and Danger per API 670 standards) with adjustable time delays to prevent spurious trips during transient conditions.

- Outputs:

- 4-20 mA Analog Output: Proportional to the measured vibration level for trending or external recording.

- Relay Outputs: Dedicated relay contacts for each alarm level to trigger external annunciators or shutdown circuits.

- Buffered Sensor Output: A replicated raw sensor signal for connection to diagnostic analyzers or data collectors.

- Configuration: Fully configurable via the 3500 rack’s Frame Interface Module using Bently Nevada’s configuration software. Key settings include transducer sensitivity, filter frequencies, alarm setpoints, and response times.

- Diagnostics: Continuously monitors for sensor health, generating a Sensor Fault alarm for conditions like open circuit or short circuit.

Advantages and Key Features

The BENTLY 135473-01 delivers significant advantages for reliable machine protection. Its core strength is providing continuous, high-fidelity monitoring of structural vibration, a direct indicator of mechanical condition for equipment like pumps, fans, and motors. The module’s flexible, software-configurable filtering allows precise tailoring to the machine’s dynamic characteristics, improving signal quality and alarm accuracy. It offers a robust, dual-stage alarm system that enables early warning and critical shutdown functions, aligning with industry best practices. Seamless integration within the 3500 system ensures coordinated data sharing with other monitoring modules (e.g., proximity probes, tachometers) for a comprehensive machine view. The BENTLY 135473-01 is designed for high reliability and diagnostic capability, helping to distinguish between a genuine machine fault and a sensor system failure.

Application Cases in Industry

This monitor is standard on countless industrial machines where velocity sensors are the primary monitoring method. In Power Generation, the 135473-01 monitors boiler feed pumps, induced/forced draft fans, cooling tower fans, and large motor bearings. Within Oil & Gas and Petrochemical plants, it protects pipeline booster pumps, compressor auxiliaries, and agitator drives. For Water and Wastewater Treatment, it is used on large vertical and horizontal pump sets. The BENTLY 135473-01 is also extensively deployed on HVAC chillers, Industrial Fans, Gearboxes, and various Motor-Driven equipment across all manufacturing sectors, providing API 670-compliant protection.

Comparison with Competing Products

- vs. Proximity Probe Monitors (e.g., 3500/42): Proximity probes measure shaft-relative displacement. The BENTLY 135473-01 measures case-absolute vibration velocity. They are complementary, often used on the same critical machine (e.g., a turbine) but for different purposes.

- vs. Simple Vibration Switches: Basic switches provide only a trip output. The 135473-01 offers continuous analog output, configurable dual alarms, advanced filtering, and sensor diagnostics, enabling predictive maintenance and detailed trending.

- vs. Other Vibration Monitor Cards (e.g., Emerson CSI, SKF): Competing systems provide similar velocity monitoring functionality. The BENTLY 135473-01 is distinguished by its native integration into the industry-standard 3500 platform, its compliance with stringent standards like API 670, and the global service and support network of Bently Nevada. The decision often hinges on existing site standards and system compatibility.

Selection Suggestions and Precautions

- Selection Advice:

- Transducer Matching: Accurately configure the transducer sensitivity (e.g., 100 mV/mm/s) in the BENTLY 135473-01 software. This is the single most critical parameter for accurate measurement.

- Frequency Band Selection: Set the high-pass and low-pass filters appropriately for the machine. For example, a 600 RPM motor (10 Hz) requires a high-pass filter below 10 Hz to ignore rigid body movement. Consult vibration analysis guidelines.

- Alarm Setpoint Strategy: Establish alarm setpoints based on baseline data, manufacturer guidelines, or ISO 10816 severity charts. Avoid arbitrary settings.

- Redundancy for Critical Machines: For high-availability requirements, use dual velocity sensors connected to separate 135473-01 modules in a voting logic configuration.

- Important Precautions:

- Sensor Mounting: Ensure the velocity transducer is mounted securely to a clean, flat surface on the bearing housing or casing as per the sensor manufacturer’s instructions. Poor mounting drastically affects readings.

- Cable Management: Use high-quality, shielded cable. Secure the cable to prevent damage from vibration and ensure the shield is grounded only at the rack end to avoid ground loops.

- Bypass Procedures: Follow strict Management of Change (MOC) procedures when placing the 135473-01 module’s alarms in bypass mode for maintenance activities (e.g., during startup or alignment).

- Regular Verification: Periodically verify the health of the measurement loop by comparing the 4-20 mA output or system display with a portable vibration analyzer reading taken at the same location.

DS200DCFBG1B PLC

2711-B6C8L1 PLC

6FC5203-0AD10-0AA0 PLC

6SE7021-3TP50-Z=43+G91+K80

MVI46-MCM

6GK1210-0SA00 PLC

LEYBOLD CM330 PLC

1785-TR10B2 PLC

6EV3054-OFC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922