Description

Product Overview and Introduction

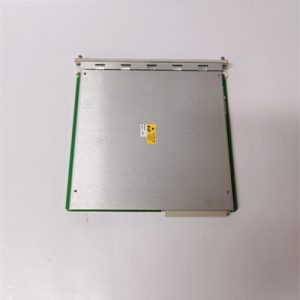

The BENTLY 133396-01 is a high-precision vibration monitoring and protection module, specifically a signal conditioning card or interface module from Bently Nevada, a Baker Hughes business and a global leader in asset condition monitoring. This component is an integral part of Bently Nevada’s 3500 or System 1* series monitoring systems, which are critical for protecting and managing large, high-value rotating machinery such as turbines, compressors, and pumps. The primary role of the BENTLY 133396-01 is to accept raw signals from proximity probes, accelerometers, or other transducers, condition these signals, and provide the processed data to a monitoring system for vibration analysis, alarming, and machinery protection.

Detailed Product Parameters and Specifications

This module’s functionality is defined by precise electrical and signal processing parameters:

- Primary Function: Signal Conditioner / Monitoring Module (likely a specific channel card such as for a 3500/42M Proximitor Monitor or similar). It powers the transducer, conditions its signal, and extracts key vibration parameters.

- Input Signal: Accepts input from eddy-current proximity probes (for measuring shaft displacement, speed, and phase) or from velocity sensors/accelerometers. Key specifications include input sensitivity (e.g., 200 mV/mil for displacement) and required probe power (typically -24 V DC).

- Conditioned Outputs: Provides processed output signals such as:

- Analog Outputs: 4-20 mA or +/-10 V DC signals proportional to vibration amplitude (e.g., peak-to-peak displacement, velocity) for chart recorders or DCS/PLC integration.

- Digital/Alarm Outputs: Relay contacts that change state based on user-configurable alarm (Alert, Danger) setpoints.

- Keyphasor® Reference Signal: A conditioned square wave pulse used for phase and speed measurement.

- Dynamic Range & Frequency Response: Defines the range of vibration amplitudes and frequencies it can accurately measure (e.g., 0 to 1000 Hz, 0 to 200 mils pk-pk).

- Power Supply: Operates on the rack’s backplane power, typically +/-15 V DC and +5 V DC.

- Configuration: Parameters like alarm setpoints, calibration values (mV/mil), and filter settings are configured via the monitoring system’s software or front-panel interface.

Key Advantages and Distinctive Features

The BENTLY 133396-01 module provides critical benefits for machinery health management:

- High Accuracy and Reliability: Delivers precise, repeatable measurement of vibration parameters, which is essential for detecting early signs of machinery faults like unbalance, misalignment, and bearing wear.

- Robust Signal Conditioning: Effectively filters out electrical noise and provides stable power to the transducer, ensuring signal integrity even in the electrically noisy environment of an industrial plant.

- Integrated Machinery Protection: The module’s configurable alarm relays provide a direct, hardwired path to initiate equipment shutdown (permissive or trip) if vibration levels exceed safe limits, preventing catastrophic failures.

- Seamless System Integration: As a genuine Bently Nevada component, it integrates flawlessly into the 3500 rack framework, providing data to the system’s displays, communication modules, and higher-level software like System 1* for advanced diagnostics.

- Diagnostic Data Source: The high-fidelity conditioned signal is the foundation for all subsequent analysis, enabling predictive maintenance programs and root cause analysis of machinery problems. The reliable operation of the BENTLY 133396-01 is therefore fundamental to any condition-based maintenance strategy.

Application Scenarios and Case Studies

This module is essential for monitoring critical rotating equipment across multiple industries:

- Power Generation: Monitoring turbine-generator shafts (main, exciter), boiler feed pumps, and induced draft fans for vibration in coal, gas, and nuclear plants.

- Oil & Gas: Protecting centrifugal and reciprocating compressors in LNG facilities, gas pipeline stations, and refineries.

- Petrochemical & Chemical: Monitoring large pumps, mixers, and reactor agitators to prevent unplanned shutdowns.

- Marine: Monitoring main propulsion turbines, gearboxes, and thrust bearings on large vessels.

- Pulp & Paper: Protecting critical high-speed machinery like paper machine rolls and refiners.

A typical application case involves a natural gas compressor station. A BENTLY 133396-01 module in a 3500 rack monitors the radial vibration of the compressor’s high-speed shaft. When vibration levels begin to trend upwards due to developing rotor imbalance, the module triggers an “Alert” alarm. Maintenance is scheduled based on this warning, and a balance correction is made during a planned outage, avoiding a forced shutdown and potential severe damage to the compressor.

Comparison with Competing Products

Compared to similar vibration monitoring modules from competitors like Emerson (CSI 6500 system cards), Schenck (Vibrotest series), or Rockwell Automation/Entek, the BENTLY 133396-01 holds a premier position:

- Industry Standard for High-Criticality Machinery: Bently Nevada is often considered the de facto standard for the most critical machinery protection applications, particularly in the oil & gas and power sectors, offering proven performance and extensive field history.

- System Cohesion: Its strength lies in being part of a complete, integrated hardware and software ecosystem (3500 rack + System 1* software), providing a seamless workflow from measurement to diagnosis.

- Global Support and Expertise: Backed by an unmatched global network of field engineers and machinery diagnostics specialists.

Competitors may offer advantages in lower-cost solutions for less critical equipment, different form factors, or specialized analysis features. However, for mission-critical protection where reliability is non-negotiable, the Bently Nevada system and components like the 133396-01 are frequently specified.

Selection Guidelines and Important Considerations

Selecting and implementing this module requires a thorough understanding of the monitoring system:

- Exact System Compatibility: The BENTLY 133396-01 is designed for a specific monitoring rack (e.g., 3500). Verify its compatibility with your existing rack model, firmware version, and slot location. It is not a universal part.

- Transducer Matching: The module must be matched to the specific type and model of the vibration transducer (probe, extension cable, and proximitor, if separate). Mismatches will result in inaccurate readings or module damage.

- Calibration and Configuration: Proper configuration of gap voltage, scale factor (mV/mil), and alarm setpoints is absolutely critical. These settings are based on the specific machine’s mechanical characteristics and allowable vibration limits.

- Wiring and Grounding: Vibration signal wiring is highly sensitive. Use only recommended, shielded cable. Follow strict guidelines for grounding (typically single-point ground at the rack) to avoid ground loops that introduce noise.

- Safety and Bypassing: Never bypass or disable a vibration protection channel without following strict management-of-change (MOC) procedures. The module is part of a Safety Instrumented System (SIS) for machinery protection.

- Diagnostics and Maintenance: Utilize the system’s diagnostic features to monitor the health of the module itself (e.g., OK LED, fault reports). Always refer to the official Bently Nevada manual for the 133396-01, accessible via the product link, for all installation, configuration, and safety procedures. Regular calibration checks against a known standard are recommended as part of a preventative maintenance program.

CP405 PLC DCS

3BSE004185R1 PLC

PFTL101B 2.0KN PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922