Description

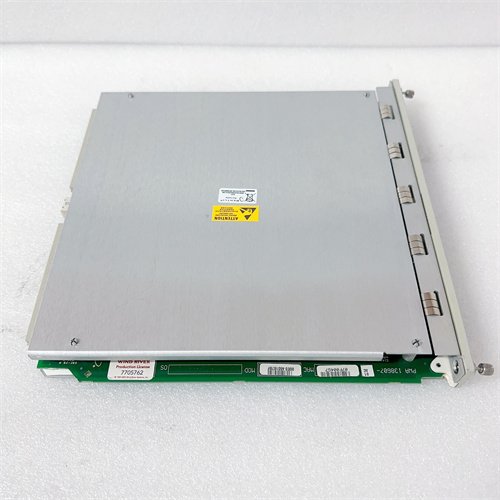

Product Description

The BENTLY 125760-01 is a 3500/42M proximity probe interface module designed specifically for Bently Nevada’s 3500 Series machinery protection systems, the industry-standard platform for critical rotating equipment monitoring in power generation, oil and gas, and industrial processing applications. This advanced I/O module provides four independent channels for eddy current proximity probe signal conditioning, enabling continuous monitoring of shaft vibration, axial position, eccentricity, and speed measurements. The BENTLY 125760-01 interfaces directly with Bently Nevada 3300 XL and 7200 series proximity probes, converting probe impedance variations into standardized DC voltage signals proportional to displacement. Engineered for API 670 compliant machinery protection applications, this module operates within Bently Nevada’s triple modular redundant architecture for critical turbine and compressor installations. The BENTLY 125760-01 mounts in 3500 Series racks and communicates with 3500/20 chassis interface modules for integration with plant distributed control systems and asset management platforms.

Product Parameters

- Model: BENTLY 125760-01

- Product Type: Proximitor I/O Module, 4 Channel

- System Compatibility: Bently Nevada 3500 Series Machinery Protection System

- Channel Count: 4 independent proximity probe inputs

- Probe Compatibility: 3300 XL 5 mm, 8 mm, 11 mm; 7200 series; 3300 series

- Input Signal: Eddy current displacement, -4 to -20 V DC (negative slope)

- Output Signal: 0 to -10 V DC proportional to displacement

- Frequency Response: 0 to 10 kHz (radial vibration), 0 to 1 kHz (axial position)

- Accuracy: ±0.1% of full scale at 25°C

- Gap Voltage Range: -1 to -19 V DC (programmable alarm setpoints)

- Transducer Power: -24 V DC from module, short circuit protected

- Buffered Outputs: 4 x BNC connectors on front panel for dynamic signal access

- Alarms: 2 per channel (Danger, Alert), programmable setpoints and hysteresis

- Indicators: Per-channel OK LED, alarm status LED, module OK LED

- Communication: 3500 rack backplane to Rack Interface Module

- Power Consumption: 12 W maximum from 3500 chassis

- Operating Temperature: 0°C to 65°C

- Certifications: CE, UL, CSA, ATEX Zone 2, FM Class I Div 2, API 670, DNV/GL marine type approval

Advantages and Features

The BENTLY 125760-01 delivers industry-leading measurement integrity through its proprietary Proximitor signal conditioning technology, which maintains exceptional linearity and temperature stability across the entire -4 to -20 V DC operating range. Unlike universal analog input modules requiring external signal converters, the BENTLY 125760-01 provides fully integrated transducer excitation, signal demodulation, and linearization specifically optimized for eddy current displacement measurement. Each of the four independent channels operates with complete electrical isolation, preventing fault propagation between measurement points and enabling true per-channel redundancy configurations. The module’s dual alarm setpoints per channel (Alert and Danger) provide two-stage warning capability, allowing operator intervention before machinery shutdown thresholds are reached. Front panel buffered outputs (BNC connectors) enable real-time dynamic signal access for external diagnostic equipment including oscilloscopes and spectrum analyzers without disturbing protection functions. The BENTLY 125760-01 incorporates continuous self-verification of internal reference voltages, input signal validity, and communication integrity, with any detected fault immediately communicating to the 3500 rack interface module. Comprehensive transient suppression on all field connections protects sensitive measurement electronics from lightning-induced surges and switching transients common in turbine generator installations. The module supports Bently Nevada’s Timex Asset Management software, providing predictive maintenance insights through long-term trend analysis of gap voltages and vibration signatures.

Application Cases in Application Fields

- Steam Turbine Generators: Deployed on 800 MW coal-fired turbine-generators, multiple BENTLY 125760-01 modules provide API 670 compliant radial vibration and thrust position monitoring, with Alert and Danger setpoints coordinated with turbine OEM specifications for overspeed protection system integration.

- Gas Turbine Compressor Trains: Installed on LNG plant propane compressor trains driven by Frame 5 gas turbines, the BENTLY 125760-01 monitors both turbine and compressor shaft vibration through 16 proximity probes, its four-channel density optimizing 3500 rack utilization.

- Hydroelectric Generators: Utilized on vertical shaft Francis turbine-generators, the BENTLY 125760-01 measures turbine guide bearing clearance and thrust runner axial position, its submerged probe compatibility enabling reliable operation in water-lubricated bearing applications.

- Pipeline Centrifugal Compressors: Applied on natural gas transmission compressor stations, this module monitors high-speed compressor shaft vibration, with the BENTLY 125760-01‘s 10 kHz frequency response capturing subsynchronous vibration components indicative of incipient surge conditions.

- Critical Process Pumps: Implemented on boiler feedwater pumps in combined cycle power plants, the BENTLY 125760-01 provides continuous vibration monitoring for high-energy pump sets, enabling predictive maintenance scheduling based on vibration trend analysis.

Comparison with Competing Products

| Feature | BENTLY 125760-01 | EPRO MMS6110 | GE BK685 | Vibro-meter VM600 |

|---|---|---|---|---|

| Channels per Module | 4 | 2 | 2 | 2 |

| Probe Compatibility | Bently Nevada 3300/7200 | EPRO PR642x | GE Bentley legacy | Vibro-meter proprietary |

| Frequency Response | 0–10 kHz | 0–10 kHz | 0–5 kHz | 0–20 kHz |

| Buffered Outputs | Yes (BNC front panel) | Yes (SMB rear) | Yes (BNC) | Yes (BNC) |

| Alarm Setpoints | 2 per channel (Alert/Danger) | 2 per channel | 1 per channel | 2 per channel |

| System Integration | 3500 Series native | MMS 6000 native | Mark VI | VM600 native |

| API 670 Compliance | Full | Full | Partial | Full |

| Hot-Swap Capable | Yes | Yes | No | Yes |

| Typical Cost Position | High | Mid-High | Mid | High |

The BENTLY 125760-01 offers significant advantages in channel density (4 channels) compared to EPRO’s MMS6110 and GE’s BK685 (2 channels each), providing 2:1 rack space savings in large turbine monitoring installations. While Vibro-meter VM600 offers superior frequency response (20 kHz), this capability exceeds API 670 requirements for most heavy rotating equipment. The BENTLY 125760-01‘s native compatibility with Bently Nevada’s industry-dominant 3300 XL probe family provides seamless retrofit capability for the vast installed base of Bently Nevada monitoring systems. For facilities standardized on Bently Nevada 3500 Series monitoring infrastructure, the BENTLY 125760-01 represents the only fully supported, configuration-managed proximity probe interface solution.

Selection Suggestions and Precautions

- System Compatibility Verification: Confirm that your 3500 Series rack and Rack Interface Module (3500/20) support the BENTLY 125760-01; all 3500 systems with firmware revision 2.0 or later are compatible, but early systems may require I/O module firmware updates.

- Probe Type Matching: Verify that installed proximity probes are compatible with the BENTLY 125760-01; 3300 XL 5mm, 8mm, and 11mm probes are fully supported; 7200 series probes require appropriate extension cables with correct impedance characteristics.

- Channel Configuration: Each BENTLY 125760-01 channel requires software configuration for measurement type (radial vibration, axial position, eccentricity, speed) using Bently Nevada’s 3500 Framework configuration software; incorrect configuration results in erroneous measurements and potential nuisance alarms.

- Gap Voltage Setpoints: Program Alert and Danger gap voltage setpoints with appropriate deadband (2–5% typical) to prevent alarm chattering; consult turbine OEM specifications for acceptable shaft position operating windows.

- Buffered Output Utilization: The BENTLY 125760-01 front panel BNC outputs provide direct dynamic signal access; terminate unused BNC connectors with 50 Ω caps to prevent electromagnetic interference ingress.

- Cable Shield Grounding: The BENTLY 125760-01 requires single-point grounding of probe extension cable shields at the 3500 rack entry; do not ground shields at probe end or intermediate junction boxes to prevent ground loops.

- Spare Parts Strategy: Given the BENTLY 125760-01‘s critical role in machinery protection and typical lead times of 10–14 weeks, maintain configured spare modules for each turbine installation; store in static-shielded packaging with quarterly operational verification.

- Environmental Installation: Mount the BENTLY 125760-01 in clean, vibration-free 3500 racks; turbine deck mounting requires external isolation or remote location in separate instrument cabinets to meet vibration specifications.

- Proof Testing Requirements: API 670 requires periodic proof testing of machinery protection systems; develop procedures for BENTLY 125760-01 channel validation using secondary injection test equipment without requiring machinery shutdown.

- Obsolescence Awareness: The BENTLY 125760-01 remains in active production with committed Bently Nevada support; however, 3500 Series technology is mature; facilities planning major capital projects should evaluate 3500 Series next-generation platforms.

- Firmware Compatibility: Verify BENTLY 125760-01 firmware revision compatibility with your 3500/20 Rack Interface Module and 3500 Framework software version; firmware mismatches cause communication faults and unrecognized configuration parameters.

- Extension Cable Requirements: The BENTLY 125760-01 requires Bently Nevada-specified extension cables with proper capacitance characteristics (approximately 100 pF/ft); non-standard extension cables alter system frequency response and gap voltage linearity.

- Marine Installation: For ABS or DNV certified marine applications, verify that BENTLY 125760-01 modules are installed with conformal coated options (suffix “C”) to provide adequate protection against salt spray and humidity in engine room environments.

- Documentation Requirements: Maintain site-specific BENTLY 125760-01 configuration records including channel assignments, probe serial numbers, calibration certificates, and alarm setpoint rationalization documentation required for regulatory compliance and insurance surveys.

TRIC0NEX 4609 PLC

TRICONEX 8110 PLCDCSIPC

TRICONEX 8111 PLC

TRIC0NEX 8312 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922