Description

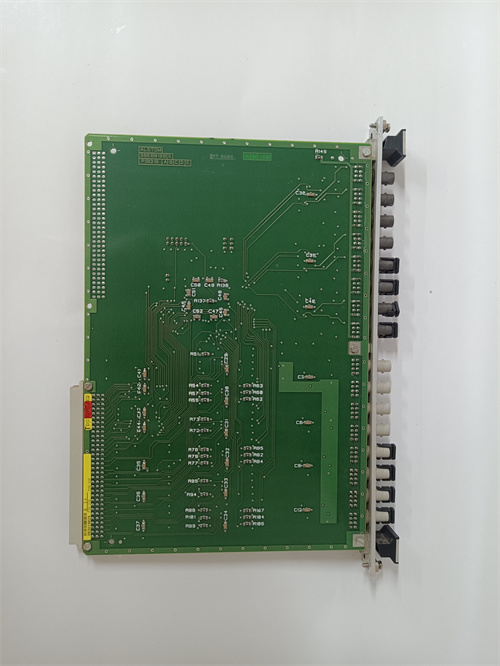

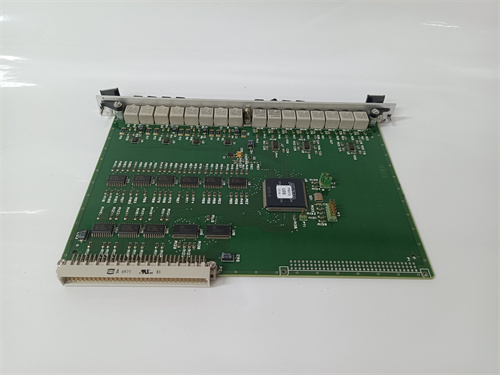

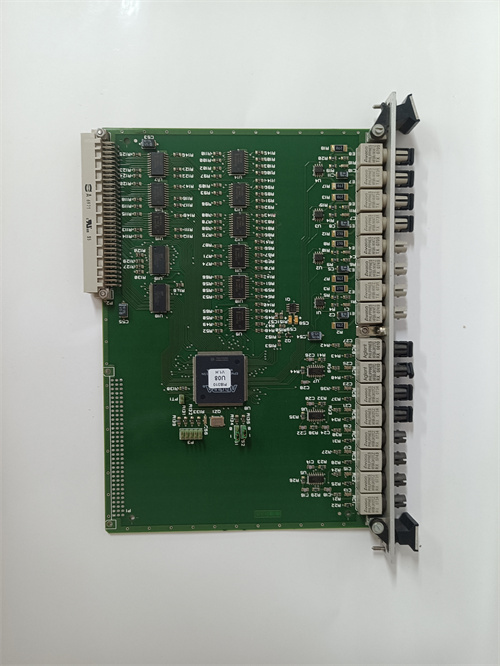

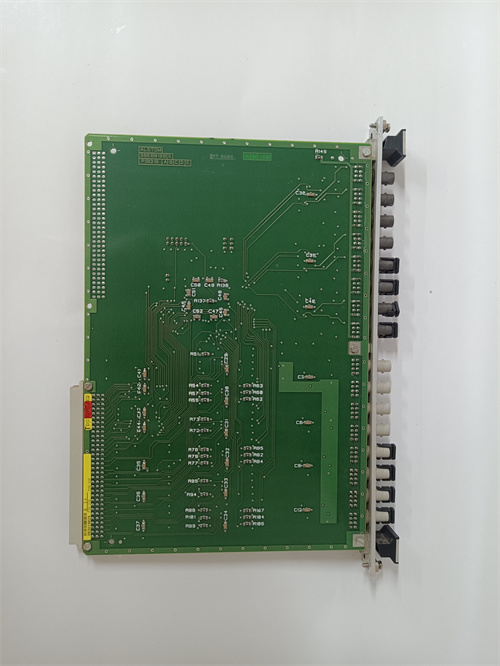

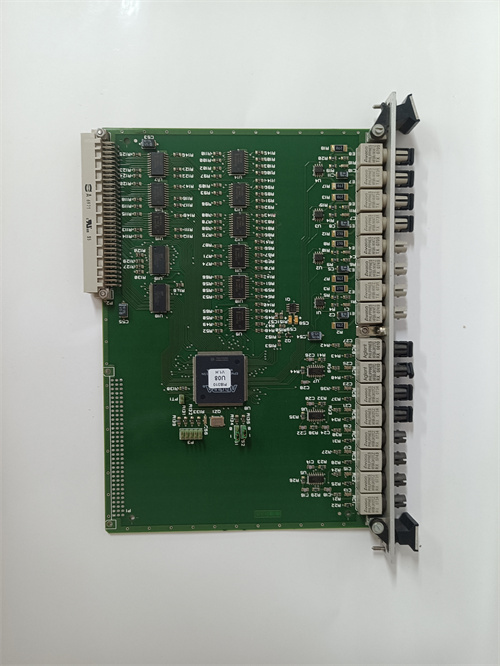

Product Description

Product Parameters

- Product Type: Industrial grade PLC digital input module, high-speed signal collection spare part

- Working Voltage: DC 24V±15%, adaptive to industrial conventional DC power supply system

- Input Channels: 32-channel independent digital input, no mutual interference between channels

- Input Signal Type: NPN/PNP bipolar compatible, no jumper switching required

- Input Response Time: ≤1ms, support high-speed on-site signal collection

- Communication Interface: Profibus-DP/RS485, dual mainstream industrial communication protocol compatible

- Operating Temperature Range: -40℃~+75℃, ultra-wide temperature industrial adaptation

- Protection Grade: IP65, dustproof, waterproof, anti-mechanical impact

- Installation Method: 35mm standard DIN rail card installation, native support for hot swap

- Insulation Resistance: ≥200MΩ (500V DC), excellent electrical isolation performance

- Surge Withstand Voltage: 4kV, strong resistance to power grid fluctuations and on-site surge impact

- Power Consumption: ≤5W, low power consumption and energy-saving design

- Electromagnetic Compatibility: Complies with IEC 61131-2 industrial electromagnetic compatibility standards

- Design Service Life: Continuous operation ≥100,000 hours, industrial-grade long life

Advantages and Features

- High-density channel integration, strong scalability: ALSTOM PIB310 is equipped with 32 independent digital input channels, which can collect a large number of on-site digital signals at the same time, effectively saving the installation space of the control cabinet, and the modular design supports flexible expansion of the system without modifying the original control link.

- Ultra-high speed response, capture high-frequency signals accurately: With an input response time of only ≤1ms, ALSTOM PIB310 can accurately capture the high-frequency switch quantity signals of high-speed production lines and precision testing equipment, without signal delay or packet loss, ensuring the real-time performance of industrial control system decision-making.

- Bipolar input compatible, high on-site adaptability: Supporting NPN/PNP bipolar digital input without manual jumper switching, ALSTOM PIB310 can be directly connected to various types of on-site sensors, proximity switches and limit switches, reducing the workload of on-site debugging and improving the efficiency of project implementation.

- Hot swap design, efficient operation and maintenance: Native support for live hot swap operation, ALSTOM PIB310 can complete module replacement and maintenance without stopping the industrial control system, completely avoiding production losses caused by equipment downtime, and greatly improving the operation efficiency of the production line.

- Dual protocol compatible, flexible system integration: Supporting Profibus-DP and RS485 dual industrial communication protocols, ALSTOM PIB310 can be seamlessly connected to Alstom’s own PLC/DCS system and other mainstream brand industrial control systems, without additional protocol converters, reducing the cost of system construction.

- Industrial-grade anti-interference, stable operation in harsh environments: Through professional electromagnetic anti-interference circuit optimization and 4kV surge withstand voltage design, ALSTOM PIB310 can maintain stable signal collection in industrial sites with strong electromagnetic interference such as power plants and metallurgical workshops, without signal drift or distortion caused by environmental factors.

- Original seamless compatibility, reliable system operation: As a core spare part of Alstom’s industrial control product system, ALSTOM PIB310 is natively compatible with Alstom’s full range of PLC and DCS master control systems, with no communication mismatch or signal packet loss after access, ensuring the overall stability of the industrial control system.

Application Fields and Application Cases

Core Application Fields

Typical Application Cases

- Power Energy Industry: In the upgrade of the control system of the water supply and drainage pump station of a large thermal power plant, ALSTOM PIB310 was adopted as the core digital input module to collect the status signals of pump body operation, valve switch and liquid level switch. Its 32-channel high integration effectively optimized the layout of the control cabinet, and the high anti-interference performance resisted the strong electromagnetic interference of the power plant, ensuring the stable operation of the water supply and drainage system with zero signal failure after commissioning.

- Metallurgical Steel Industry: In the cold rolling production line of a large stainless steel enterprise, ALSTOM PIB310 was used to collect the status signals of rolling mill rollers, conveying roller tables and positioning limit switches. Its ultra-high speed response characteristic accurately captured the high-frequency switch signals of the production line, and the bipolar input compatibility was directly connected to various on-site sensors, which improved the control precision of the cold rolling production line and increased the product qualification rate by 2.5%.

- Intelligent Manufacturing Industry: In the automated assembly line of a new energy vehicle battery factory, ALSTOM PIB310 was adopted as the unified digital signal collection module to collect the status signals of robotic workstations, conveying equipment and testing fixtures. Its hot swap design realized non-stop maintenance of the production line, and the high-density channel integration saved a lot of control cabinet space, which was conducive to the compact design of the intelligent production line and improved the overall automation level of the factory.

- Rail Transit Industry: In the signal control system transformation project of an intercity railway marshalling station, ALSTOM PIB310 was used to collect the status signals of track turnouts, signal machines and shield doors. Its IP65 protection level adapted to the harsh outdoor environment of the marshalling station, and the dual protocol compatibility realized seamless docking with the existing DCS system of the station, ensuring the continuous and stable operation of the railway signal control system.

Comparison with Competing Products

| Comparison Dimension | ALSTOM PIB310 | Same Type Imported Brand PLC Digital Input Module | Same Type Domestic PLC Digital Input Module |

|---|---|---|---|

| Input Channel Quantity | 32 independent channels | 16/24 independent channels | 8/16 channels (partial sharing) |

| Input Response Time | ≤1ms, ultra-high speed | ≤3ms, medium speed | ≤5ms, conventional speed |

| Bipolar Compatibility | NPN/PNP, no jumper switching | NPN/PNP, need jumper switching | Partial support, limited channels |

| Hot Swap Function | Native support, live operation | Partial model support, additional configuration required | Few models support, high damage risk |

| Communication Protocol | Profibus-DP/RS485, dual protocol | Only 1 mainstream protocol | Only RS485, single protocol |

| Operating Temperature Range | -40℃~+75℃, ultra-wide temperature | -30℃~+65℃, conventional wide temperature | -20℃~+55℃, ordinary temperature zone |

| Surge Withstand Voltage | 4kV, strong anti-interference | 2kV, medium anti-interference | 1.5kV, general anti-interference |

| Continuous Service Life | ≥100,000 hours | ≥70,000 hours | ≥50,000 hours |

| System Compatibility | Full compatibility with mainstream brands, original seamless docking | Only compatible with its own brand system | Compatible with conventional PLC, need adaptation for high-end systems |

Selection Suggestions

- Priority selection for high-density signal collection scenarios: If the industrial control system needs to collect a large number of on-site digital signals and pursue the compact design of the control cabinet, such as large-scale industrial production lines and intelligent factory control systems, ALSTOM PIB310 with 32 independent channels is the first choice, which can realize one-stop signal collection and reduce the number of modules configured.

- Priority selection for high-speed signal collection scenarios: For high-speed production lines, precision testing equipment and other scenarios that require accurate capture of high-frequency switch quantity signals, ALSTOM PIB310 with an ultra-high speed response of ≤1ms is recommended to ensure the real-time performance and accuracy of system control.

- Priority selection for harsh industrial environment: In industrial sites with harsh environments such as strong electromagnetic interference, high dust and large temperature changes, such as power plants, metallurgical workshops and mining areas, ALSTOM PIB310 with industrial-grade anti-interference and ultra-wide temperature design can effectively reduce equipment failures caused by the environment.

- Adaptive selection for Alstom industrial control system: If the on-site industrial control system is Alstom’s series PLC/DCS master control system, ALSTOM PIB310 is preferred, and the original native compatibility can realize seamless signal transmission and avoid communication problems such as signal packet loss and mismatch.

- Selection for non-stop operation and maintenance demand scenarios: For enterprises sensitive to production line downtime losses and requiring non-stop maintenance of equipment, such as continuous chemical production and new energy battery intelligent manufacturing, ALSTOM PIB310’s hot swap design can meet the operation and maintenance needs and greatly improve production efficiency.

- Selection for multi-brand system integration scenarios: If the on-site industrial control system is a multi-brand PLC/DCS integrated layout, ALSTOM PIB310 with dual protocol compatibility is selected, which can realize seamless docking with different brand systems without additional protocol converters and improve the efficiency of system integration.

- Priority selection for on-site sensor mixed scenarios: If the on-site sensors, proximity switches and other equipment are mixed with NPN and PNP types, ALSTOM PIB310 with bipolar non-jumper compatibility is selected to save the on-site jumper debugging work and speed up the project implementation progress.

Precautions

- Installation Norms: ALSTOM PIB310 is installed with 35mm standard DIN rail card, ensure the module is clamped firmly during installation, and keep a distance of ≥8cm from the surrounding high-power heating equipment to ensure good heat dissipation; do not stack other components on the module surface to avoid blocking the heat dissipation holes.

- Power Supply Requirements: Provide pure DC 24V power supply for the module, and configure surge protectors and power filters at the power input end to avoid damage to the internal circuit of the module caused by power grid fluctuations and excessive clutter; it is strictly forbidden to connect AC voltage to the power input end to prevent the module from being burned.

- Wiring Operation: Strictly distinguish the power supply end, communication end and each input channel during wiring, and fasten the wiring terminals with a professional torque wrench to avoid poor contact leading to abnormal signal collection; the signal line is recommended to use shielded wire and single-end grounding to reduce electromagnetic interference.

- Hot Swap Operation: Although hot swap is supported, it is necessary to disconnect the signal input of the corresponding channel first before plugging and unplugging the module to avoid damage to the module or the main control system caused by instantaneous current impact; hold the module buckle when plugging and unplugging, and it is strictly forbidden to pull the line directly.

- Parameter Debugging: Debug the module parameters through Alstom’s original PLC programming software, and it is strictly forbidden to modify the parameters with non-original software; check the module communication status and channel signal collection status one by one after debugging to ensure that all indicators are normal.

- Environmental Protection: Although it has an IP65 protection grade, avoid placing ALSTOM PIB310 directly in water or in a strong corrosive gas environment; for high-corrosion sites such as petrochemical industry, regularly clean the dust and condensation on the module surface with dry compressed air.

- Communication Settings: Unify the communication protocol and baud rate with the PLC/DCS main control system in advance before docking; when using remote communication, add a signal amplifier to the communication line to avoid signal attenuation leading to abnormal communication.

- On-site Docking: When docking with on-site sensors and switches, confirm the signal type (NPN/PNP) in advance, and do not connect the over-range signal to the module to avoid damage to the input channel; the on-site equipment should be grounded reliably to reduce the interference of the equipment itself on the signal.

- Daily Maintenance: Regularly check the module’s running indicator lights, wiring terminals and shell temperature during daily maintenance. If the indicator lights flash, the terminals are loose or the temperature is abnormal (>60℃), stop the machine for troubleshooting immediately; regularly check the grounding status of the shielded wire to ensure reliable grounding.

- Spare Parts Replacement: When the module fails or the components are damaged, replace them with Alstom’s original spare parts and the same model module, and it is strictly forbidden to use non-original spare parts or cross-model replacement; recheck the signal collection status of all channels after replacement to ensure consistency with the original system parameters.

- Storage and Transportation: Unused ALSTOM PIB310 should be stored in a dry and ventilated environment with a temperature of 0℃~+35℃ and a humidity of ≤60%, avoiding direct sunlight, rain and violent collision; use the original shockproof, moisture-proof and anti-static packaging during transportation, and isolate the modules with anti-static foam to prevent the internal chip from being damaged by static electricity.

ACS311-4P1-3 PLCCPU

ACS311-6P6-3 PLC

ACS350-03U-04A1-4 PLC

ACS350-03U-05A6-4 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922