Description

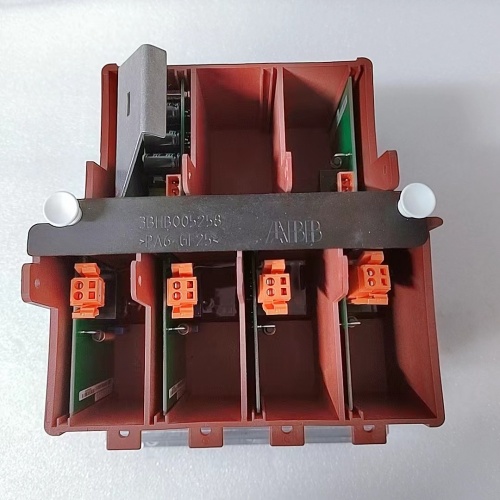

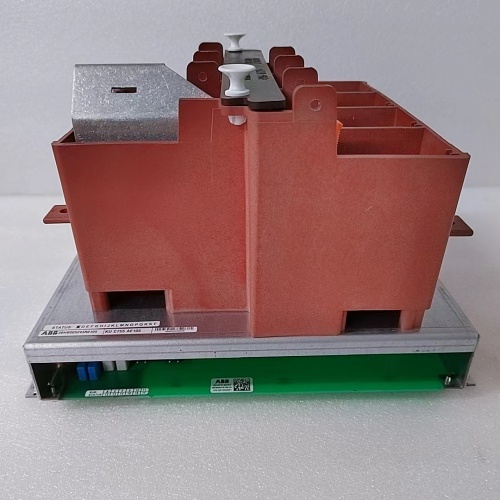

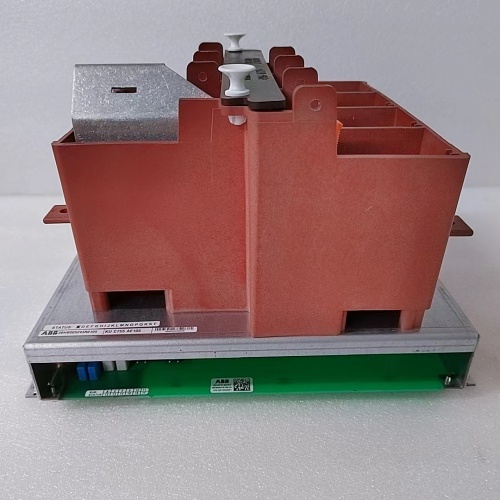

Product Overview: ABB KUC755AE105

Core Technical Specifications

- Control Capabilities:

- ABB KUC755AE105 supports advanced drive control modes, including vector control (for precise torque/speed regulation), scalar control (for simple applications), and field-oriented control (FOC) for synchronous/asynchronous motors;

- Enables multi-motor coordination: Can synchronize up to 4 ACS880 drives (e.g., for tandem rolling mills or multi-compressor systems) with a synchronization accuracy of ±0.1% of rated speed;

- Built-in process control functions: Includes PID controllers for pressure, flow, or temperature regulation, eliminating the need for external process controllers.

- Communication Interfaces:

- Equipped with a comprehensive set of industrial communication ports:

- Gigabit Ethernet (supports Profinet IRT, Ethernet/IP, and Modbus TCP) for high-speed data exchange with PLCs (e.g., ABB AC800M, Siemens S7-1500) and SCADA systems;

- RS-485 (Modbus RTU) for local configuration and connection to auxiliary devices (e.g., HMI panels);

- ABB’s proprietary DriveLink interface for direct, low-latency communication with ACS880 inverter modules (latency <1 ms).

- Equipped with a comprehensive set of industrial communication ports:

- Environmental & Electrical Ratings:

- Operating temperature range: -25 °C to +60 °C, with passive cooling (no fans) to avoid dust ingress—ideal for dirty environments like steel mills;

- Protection class: IP20 (for cabinet mounting), with galvanic isolation (500 V AC/1 min) between communication and power circuits to resist electromagnetic interference (EMI) per IEC 61000-6-2;

- Power supply: 24 V DC (19.2–28.8 V DC wide range), with low power consumption (<5 W) to minimize energy waste.

Key Product Advantages

- Seamless ACS880 Integration:

ABB KUC755AE105 is purpose-built for ABB’s ACS880 drives—no additional adapters or firmware patches are required. It automatically detects ACS880 hardware (e.g., power modules, I/O cards) and loads optimized control parameters, reducing drive commissioning time by up to 50% compared to third-party control units. This integration also ensures full compatibility with ACS880’s safety functions (e.g., Safe Torque Off, STO), maintaining system safety integrity.

- Dynamic Load Handling:

The module’s advanced vector control algorithm delivers exceptional dynamic performance—it can respond to load changes (e.g., sudden torque spikes in rolling mills) within 5 ms, preventing drive instability or tripping. It also includes overcurrent/overtorque protection with adjustable thresholds, safeguarding both the drive and the connected machinery.

- Flexible Programming:

ABB KUC755AE105 supports programming via ABB’s Drive composer Pro software, which offers a user-friendly interface for customizing control logic (e.g., creating custom torque limits for specific processes). It also includes a library of pre-built function blocks (e.g., motor synchronization, PID tuning) that can be dragged-and-dropped, reducing programming effort for common applications.

Typical Application Scenarios

- Steel Industry: Hot Rolling Mill Drive Control:

In a steel mill’s hot rolling line, ABB KUC755AE105 controls four ACS880 drives powering the tandem rolling mill motors (each 15 MW). It synchronizes the speed of all four motors to within ±0.05% of rated speed, ensuring uniform pressure on the steel slab and preventing defects (e.g., uneven thickness). The module’s built-in PID controller also regulates the roll gap based on slab thickness feedback, maintaining product quality.

- Marine Industry: Propulsion Drive Control:

For a large cargo ship’s propulsion system, ABB KUC755AE105 manages two ACS880 drives powering the main propeller motors (each 20 MW). It uses vector control to deliver precise torque regulation, enabling smooth acceleration/deceleration and fuel-efficient operation. The module also communicates with the ship’s PLC via Ethernet/IP to receive speed commands and send drive status data (e.g., motor temperature, power consumption).

Competitor Comparison & Selection Recommendations

| Comparison Criteria | ABB KUC755AE105 | Siemens Sinamics CU320-2 | Rockwell Allen-Bradley PowerFlex 755 Control Module |

|---|---|---|---|

| ABB ACS880 Compatibility | Native plug-and-play | Requires custom firmware | Requires gateway module |

| Multi-Motor Sync Accuracy | ±0.1% of rated speed | ±0.3% of rated speed | ±0.2% of rated speed |

| Environmental Ruggedness | -25 °C to +60 °C (passive cooling) | 0 °C to +50 °C (fan-cooled) | -10 °C to +55 °C (fan-cooled) |

- Prioritize ABB KUC755AE105 if your system uses ABB ACS880 drives—its native integration and superior synchronization accuracy are critical for high-power, multi-drive applications like rolling mills or marine propulsion.

- Choose Siemens Sinamics CU320-2 only if you use Siemens drives (e.g., Sinamics S120) and require basic multi-drive control.

- Opt for Rockwell’s PowerFlex 755 module if your setup is Rockwell-centric (e.g., ControlLogix PLCs) and operates in less harsh environments (no extreme temperatures or dust).

Usage Precautions

- Compatibility Check:

Ensure ABB KUC755AE105 is paired with compatible ACS880 drive firmware (version 5.0 or higher). Using outdated firmware can cause communication errors or control instability—check ABB’s website for firmware compatibility matrices before installation.

- Commissioning Best Practices:

Use ABB’s Drive composer Pro software to calibrate the module with the connected motor (e.g., setting motor parameters like rated voltage, current, and speed). Skipping calibration can lead to poor control performance (e.g., torque ripple) or drive tripping.

- Periodic Maintenance:

Inspect ABB KUC755AE105 every 6 months: Clean dust from ventilation slots (to prevent overheating), verify communication links (e.g., check Ethernet cable integrity), and back up the module’s configuration to ABB’s cloud or a local drive. Update firmware annually to access new features and bug fixes.

- KUC755AE105

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922