Description

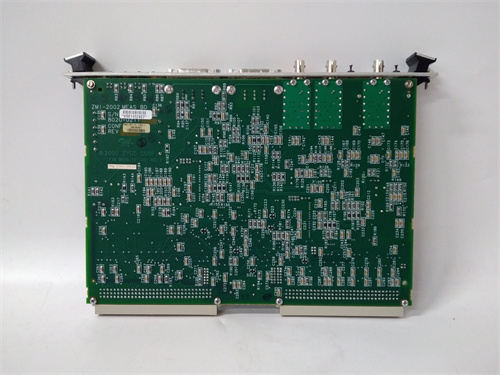

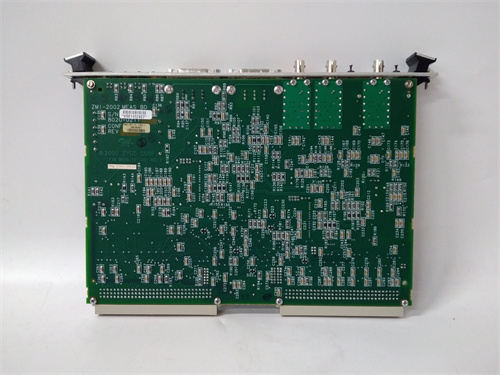

Product Overview

The ABB ZM-40-PKZ2 is a precise and robust potentiometer kit designed for the positioning and feedback of ABB PKZ series manual motor starters (MMS) or circuit breakers with motor operators. This kit is not a standalone control device but a critical interface component that enables remote status indication and potential integration into control systems. The primary function of the ABB ZM-40-PKZ2 is to translate the mechanical position (ON/OFF/TRIPPED) of a compatible PKZ motor starter’s rotary handle into a proportional resistance or voltage signal. This provides a reliable analog feedback signal to a PLC, DCS, or other monitoring device, allowing the central control system to know the exact state of the motor starter. The design of the ABB ZM-40-PKZ2 ensures accurate, long-life mechanical coupling and electrical output, making it a key component for automated systems requiring remote status monitoring of motor circuits. Its integration enhances system visibility and enables advanced diagnostic and interlocking functions.

Product Parameters

- Product Family: ABB PKZ System Accessory.

- Type: Potentiometer Kit for Position Indication.

- Compatibility: Designed for use with specific PKZ2 manual motor starters or PKZM circuit breakers with motor operators. The “40” in the model number often refers to a specific mounting size or frame.

- Electrical Output: Potentiometer (variable resistor). Typical resistance values are 1 kΩ or 2 kΩ, providing a variable voltage signal when connected to a voltage source.

- Electrical Connection: Terminates in flying leads or a connector for easy wiring to a PLC analog input module or a signal conditioner.

- Mechanical Mounting: Includes all necessary hardware (brackets, coupler, screws) for direct mechanical attachment to the rotary shaft of the target PKZ device.

- Rotation Angle: Designed to match the full rotational travel of the motor starter handle (e.g., approximately 90 degrees from OFF to ON).

- Environmental Rating: Typically designed for standard industrial panel environments (IP20).

Advantages and Key Features

The key advantage of the ABB ZM-40-PKZ2 is that it provides a simple, reliable, and cost-effective method for obtaining precise, continuous position feedback from a motor protection device without requiring complex or expensive electronic add-ons. It offers a genuine ABB-engineered mechanical interface, ensuring perfect fit, reliable coupling, and long-term durability without risk of slippage or misalignment. The potentiometric output provides a high-resolution signal, allowing the control system to distinguish not just between ON/OFF, but also intermediate positions like “TRIPPED,” which is a distinct mechanical position in many breakers. This facilitates precise remote diagnostics. The installation of the ABB ZM-40-PKZ2 is straightforward, utilizing the existing starter mounting points. Its passive design (no power required for the sensor itself) enhances reliability. The use of the ABB ZM-40-PKZ2 enables predictive maintenance and sophisticated interlocking logic based on the actual, verified state of the motor branch circuit.

Application Cases in Industry

The ABB ZM-40-PKZ2 is used in automated industrial facilities where remote monitoring of motor states is critical for process control, safety, and maintenance. Common applications include:

- Motor Control Centers (MCCs): Providing remote status feedback for each motor starter bucket to a SCADA or DCS system, allowing operators to see from the control room if a pump or fan is manually isolated, running, or has tripped.

- Water/Wastewater Treatment Plants: Monitoring the status of critical pump starters to ensure proper sequencing and provide immediate alarm if a starter is unexpectedly turned to the OFF position locally.

- Conveyor Systems: Interlocking conveyor sections by verifying the upstream motor starter is in the ON position before allowing the downstream section to start.

- HVAC Systems: Providing feedback to a building management system (BMS) on the status of large fan or chiller motor starters for energy management and fault reporting.

Comparison with Competing Products

Compared to auxiliary contacts (standard AL or SDE contacts) which provide only a discrete (on/off) signal, the ABB ZM-40-PKZ2 provides a significant advantage with its analog position feedback, allowing detection of the tripped state—a crucial diagnostic often not available from a standard auxiliary contact block. It competes with other manufacturer’s position transducers, such as Siemens’ potentiometer kits for 3VA breakers or Schneider Electric’s OF/OC/SD status switches for TeSys starters. The ABB ZM-40-PKZ2 is distinguished by its OEM-designed, mechanical compatibility and optimized coupling for PKZ devices, ensuring more reliable installation and signal accuracy than a generic universal potentiometer kit. Compared to fully electronic communication modules (e.g., a fieldbus module for the starter), the ABB ZM-40-PKZ2 is a simpler, lower-cost solution for obtaining basic but critical position data.

Selection Suggestions and Precautions

- Starter Compatibility: This is the most critical step. The ABB ZM-40-PKZ2 is designed for specific PKZ2/PKZM models and frame sizes. Verify the exact part number of your manual motor starter and cross-reference it with ABB’s accessory selection guide to ensure compatibility. The “40” must match the starter’s frame.

- Signal Conditioning: The potentiometer output is a resistance. To interface with a standard PLC analog input (typically 0-10V or 4-20mA), you will require a signal conditioning module or a simple resistor divider/power supply circuit to convert the variable resistance into a standard voltage signal.

- Mechanical Installation: Follow the mounting instructions precisely. Ensure the coupling is securely attached to the starter shaft and that the potentiometer rotates freely through its full range without binding. Improper installation can damage the potentiometer or affect the starter’s operation.

- Wiring and Shielding: Use shielded cable for the signal wires to prevent electrical noise from motors and drives from corrupting the analog feedback signal. Connect the shield to ground at the PLC end only.

- PLC Programming: In the PLC, scale the analog input signal to represent the handle’s angular position (e.g., 0% = OFF, 50% = TRIPPED, 100% = ON). Implement logic to monitor for out-of-range signals that may indicate a wiring fault or potentiometer failure.

- Environmental Limits: The ABB ZM-40-PKZ2 is typically rated for panel environments. Do not expose it to moisture, excessive dust, or corrosive atmospheres unless housed in a suitably rated enclosure.

GE IC697CHS770

IC697CHS783 DCS

GE IC697CMM711 DCS

IC697CMM742 DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922