Description

Product Description

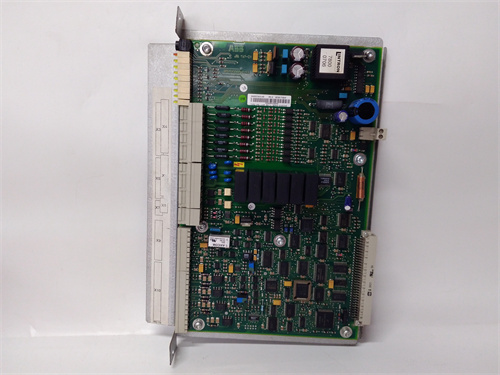

The ABB YPQ110A 3ASD573001A5 is a sophisticated, high-performance motor protection relay from ABB’s REM (Relion) series, specifically designed for advanced motor management and protection. This device, part of the Relion 600 family, functions as a comprehensive Intelligent Electronic Device (IED) that integrates protection, control, measurement, and communication for medium-voltage motors and motor-driven applications. The ABB YPQ110A 3ASD573001A5 goes beyond simple overload protection, offering a suite of features to safeguard the motor from electrical faults, monitor its condition, and optimize its operation. Its design focuses on reliability and advanced diagnostics to prevent unplanned downtime and extend motor life. Integrating the ABB YPQ110A 3ASD573001A5 (https://www.example-link-abb-product.com) into a motor control center (MCC) or switchgear provides a modern, digital solution for critical drive systems. The capabilities and robust construction of the ABB YPQ110A 3ASD573001A5 make it a key component for asset management in industries reliant on large motors.

Product Parameters / Technical Specifications

- Manufacturer: ABB

- Product Family: Relion 600 Series (Motor Protection & Control)

- Device Type: Motor Protection and Control Relay

- Model / Type Designation: YPQ110A

- Order Code / Article Number: 3ASD573001A5

- Key Protection Functions:

- Thermal Overload Protection (49) with thermal replica and unbalance bias.

- Short-Circuit / Instantaneous Overcurrent (50).

- Stalling / Locked Rotor Protection (14/51LR).

- Earth Fault Protection (50N/51N).

- Undercurrent / Underpower (37) for load loss detection.

- Starts Per Hour and Minimum Rest Time Monitoring.

- Control Functions:

- Direct control of motor contactor or circuit breaker (Start/Stop).

- Programmable logic for interlocking and sequencing.

- Measurement & Monitoring:

- Comprehensive metering (current, voltage, power, power factor, energy).

- Motor and bearing temperature monitoring via PT100 inputs.

- Event recording and disturbance recording (oscillography).

- Communication Interfaces: Supports industry-standard protocols such as Modbus RTU (RS485), PROFIBUS DP, and often IEC 61850.

- Inputs/Outputs: Multiple binary inputs (for status, commands) and relay outputs (for trip, alarm, control).

- Power Supply: Wide-range AC or DC supply (e.g., 24-250V DC / 110-240V AC).

Advantages and Key Features

- Comprehensive Motor Protection: The ABB YPQ110A 3ASD573001A5 provides a complete set of protection functions tailored to the specific thermal and mechanical characteristics of electric motors, preventing damage from overloads, phase failures, and jams.

- Advanced Condition Monitoring: Integrated temperature monitoring and load trend analysis enable predictive maintenance, allowing issues to be addressed before they cause a failure.

- Reduced Downtime: Accurate diagnostics and event recording help quickly identify the root cause of a trip, speeding up the troubleshooting and restart process.

- Communication Ready: Built-in communication capabilities allow for easy integration into SCADA, DCS, or plant asset management systems for centralized monitoring and control.

- User-Friendly Configuration: Configured using ABB’s PCM600 or similar engineering tool, allowing for flexible adaptation to specific motor parameters and application requirements.

Application Cases in Various Fields

- Mining & Minerals: Protecting critical motors on crushers, conveyors, and slurry pumps from overload and jam conditions.

- Oil & Gas: Safeguarding motors driving pumps, compressors, and fans on offshore platforms and in refineries.

- Water & Wastewater Treatment: Managing and protecting large raw water intake pumps, aeration blowers, and sludge pumps.

- Power Generation (Auxiliary Systems): Protecting boiler feed pumps, induced draft (ID) and forced draft (FD) fans, and cooling water pumps.

- Chemical & Petrochemical: Providing advanced protection for agitator motors, reactor feed pumps, and compressor drives.

Comparison with Competing Products

The ABB YPQ110A 3ASD573001A5 competes with other advanced motor protection relays such as the Siemens 7SJ82 (SIPROTEC), Schneider Electric Sepam, and GE Multilin 869. Its primary advantages are its deep integration within ABB’s electrical and automation portfolio, its strong focus on motor-specific thermal modeling, and its support for modern communication standards. Compared to traditional thermal overload relays and separate protection devices, it offers vastly superior functionality, accuracy, and diagnostic information in a single unit.

Selection Suggestions and Precautions

- Selection Advice: Select the ABB YPQ110A 3ASD573001A5 for the protection and management of medium to large, critical motors where advanced protection, condition monitoring, and system integration are required. It is ideal for new motor control centers or for upgrading existing protection schemes. Selection involves matching the relay’s current input range to the motor’s full-load current (via CTs) and ensuring the required protection functions and communication protocols are supported.

- Precautions:

- Accurate Motor Data: Correct configuration requires precise motor data from the nameplate (FLC, service factor, locked rotor current, thermal time constants). Incorrect data will compromise the accuracy of the thermal model.

- CT Selection & Wiring: Proper selection and connection of current transformers (CTs) are critical. Ensure CT ratio, accuracy class, and wiring are correct to guarantee accurate measurement and protection.

- Thermal Model Tuning: The thermal overload function may require tuning based on the motor’s actual cooling characteristics and operating environment for optimal protection.

- Testing & Commissioning: Perform comprehensive functional testing using a secondary injection test set to verify all protection settings and control logic before commissioning.

- Communication Configuration: Properly configure the communication protocol, address, and data mapping to ensure reliable integration with the control system.

ABB TU511-CS31 CO PLC

AI930S PLC

CI920AS ABB PLC

DRAO2 ABB PLC

ABB DAI05 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922